Largest Japanese Apparel Retailer

Distribution Center Project

42,000

Storage Locations

90%

High Utilization Rate

2,800 cases

Inbound/outbound Efficiency Per Hour

99.9%

Picking Accuracy

--Manual operation delivers low efficiency and is error prone

--Manual operation leads to low efficiency, low storage density and limited operational height

--Many operational errors during peak hours

--High labor cost

Our Solution

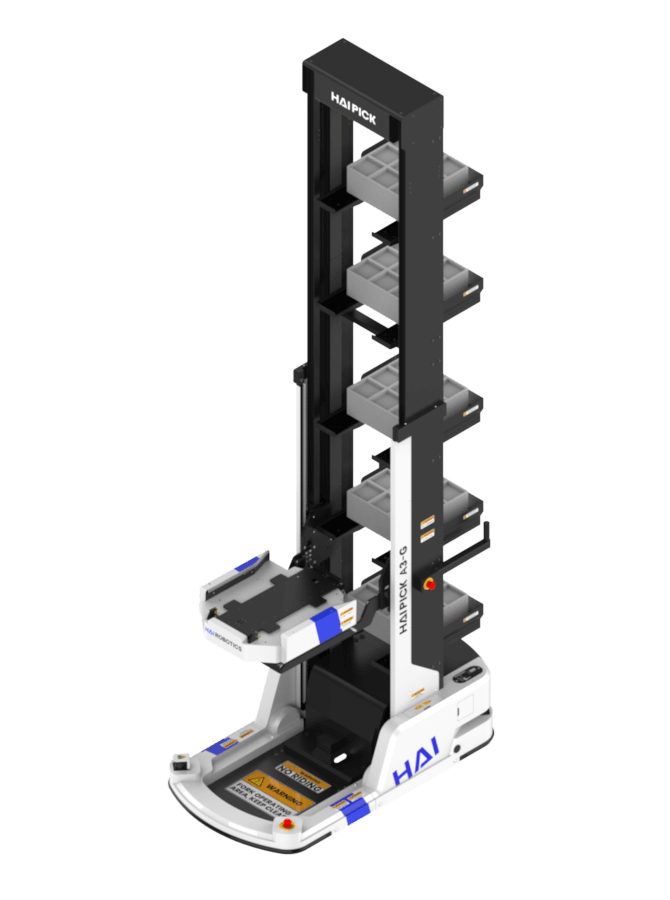

--Robot quantity & type: 130 units, A42N

--Charging stations:33

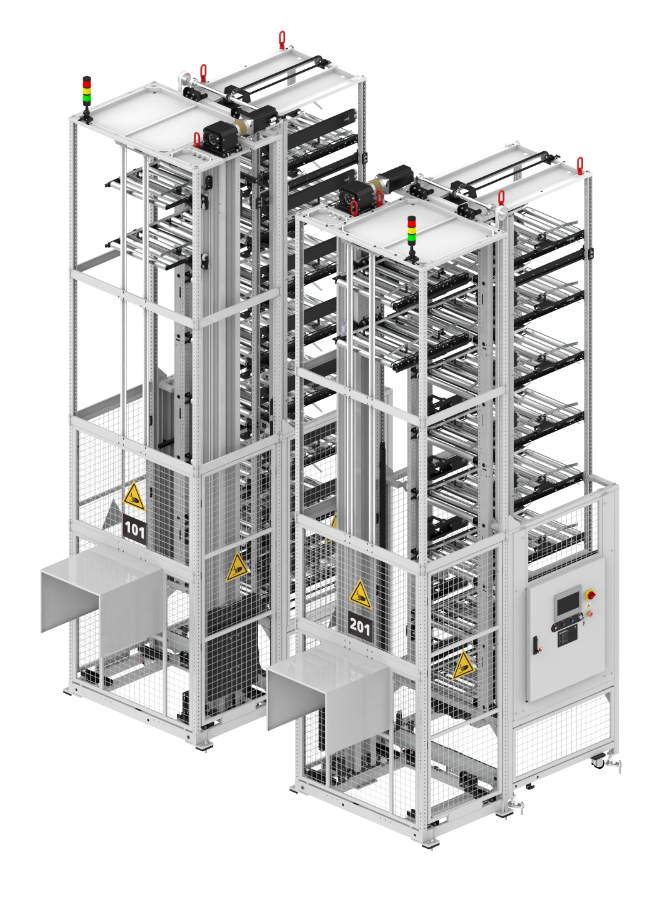

--Workstation type & quantity: 30 sets u-shaped on-conveyor picking workstation

--Shelving height: 4,300mm

--Case type/size: tote 650mm(L)×440mm(W)×300mm(H), carton 650mm(L)×440mm(W)×350mm(H) ~ 400mm(L)×300mm(W)×200mm(H)

--Warehouse area: 7,800㎡, achieved 42,000 storage locations, increasing storage density by 60%: adding storage locations in the existing warehouse space

--90% high utilization rate

--Inbound efficiency: 2,800 cases/hour; outbound efficiency: 2,800 cases/hour

--Suitable for totes and cartons