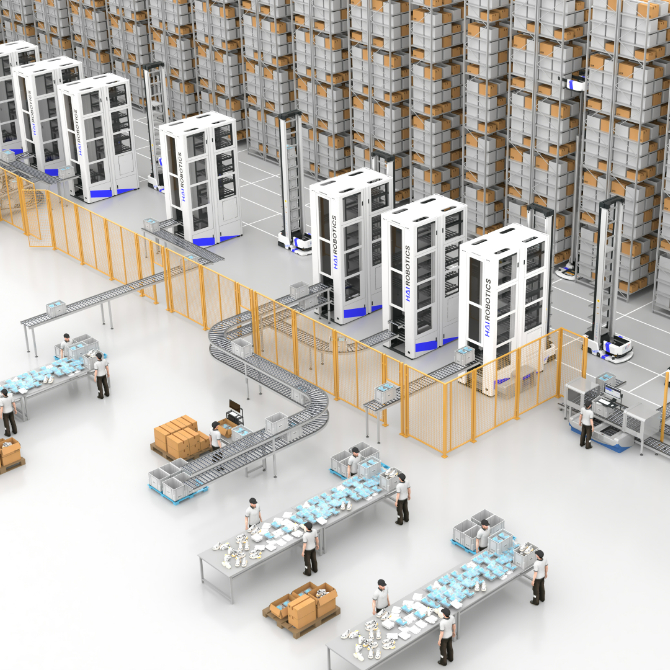

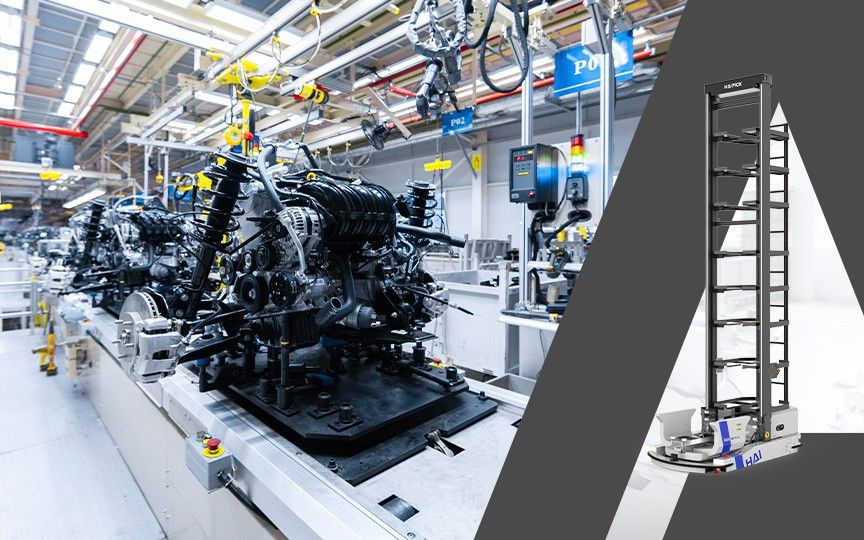

Multi-Layer ACR

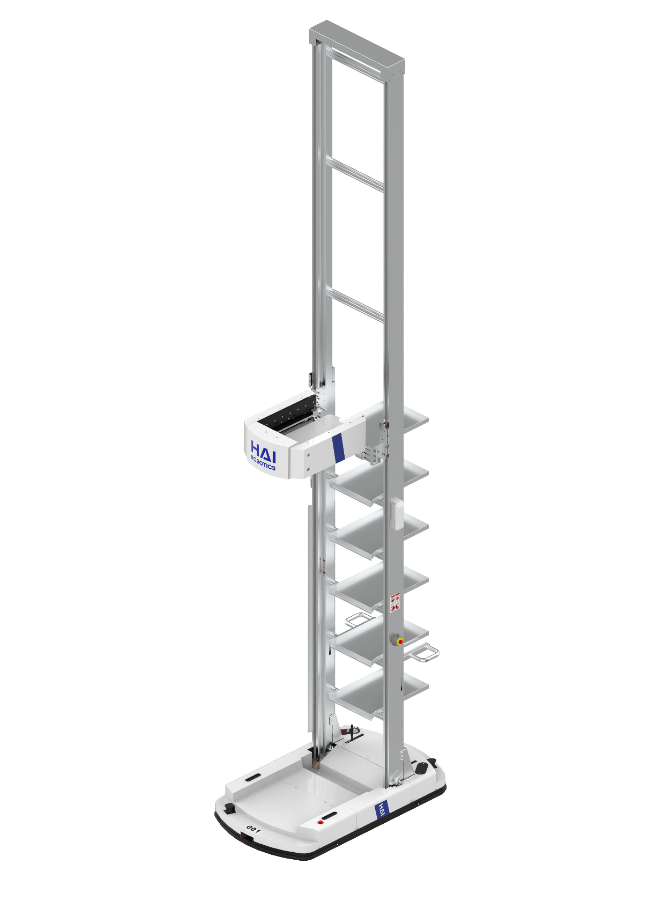

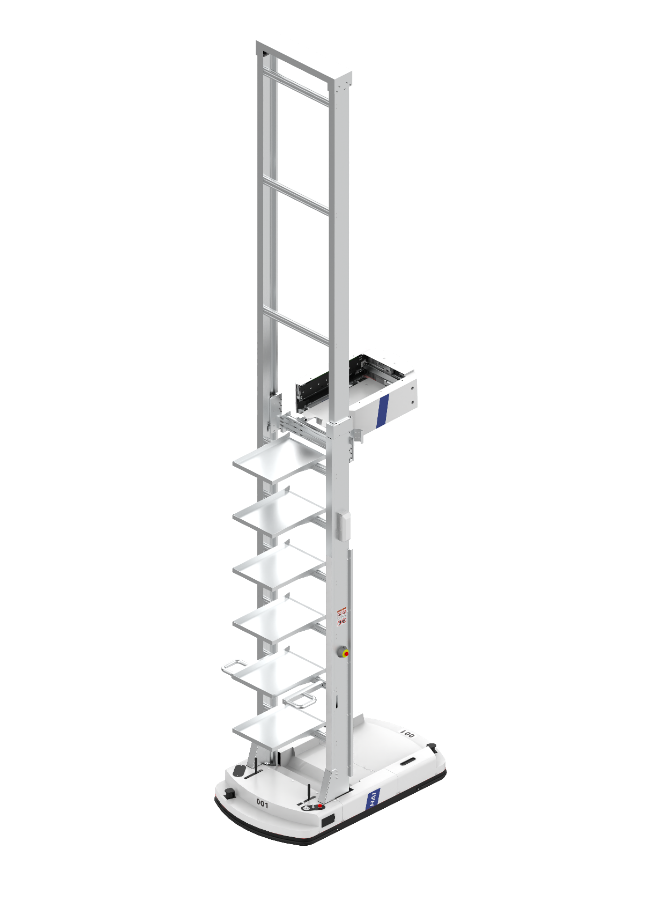

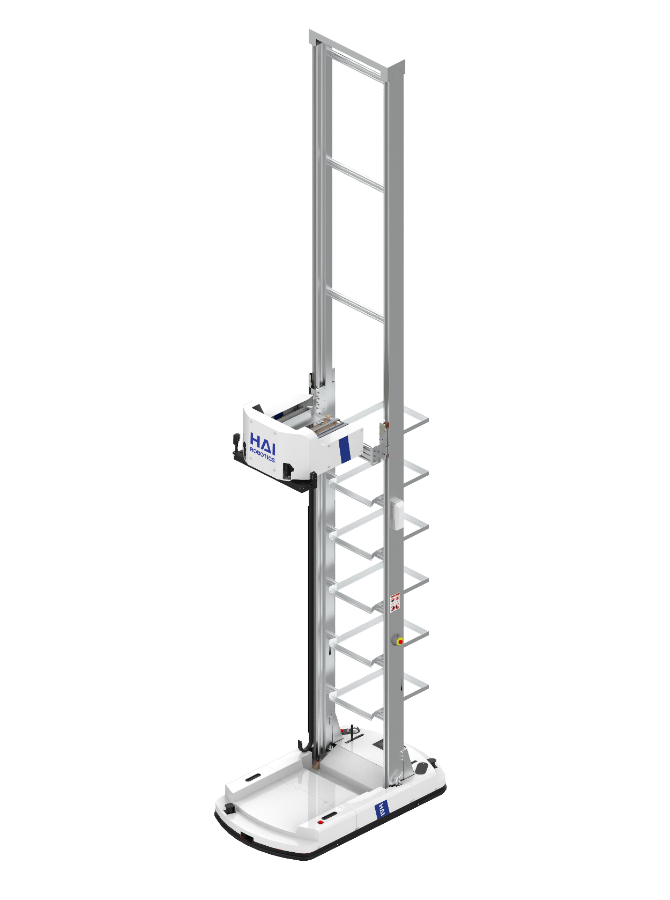

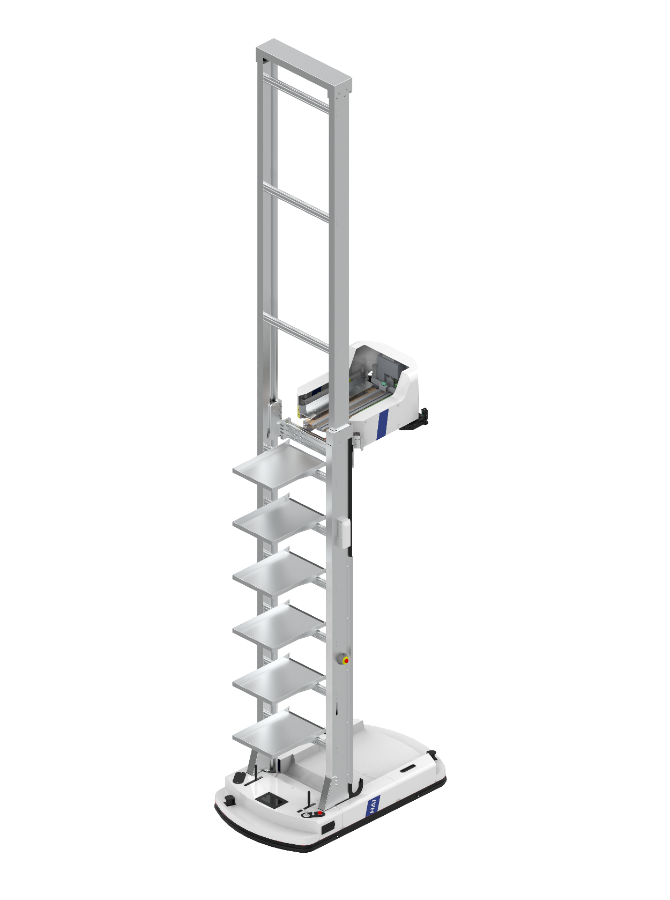

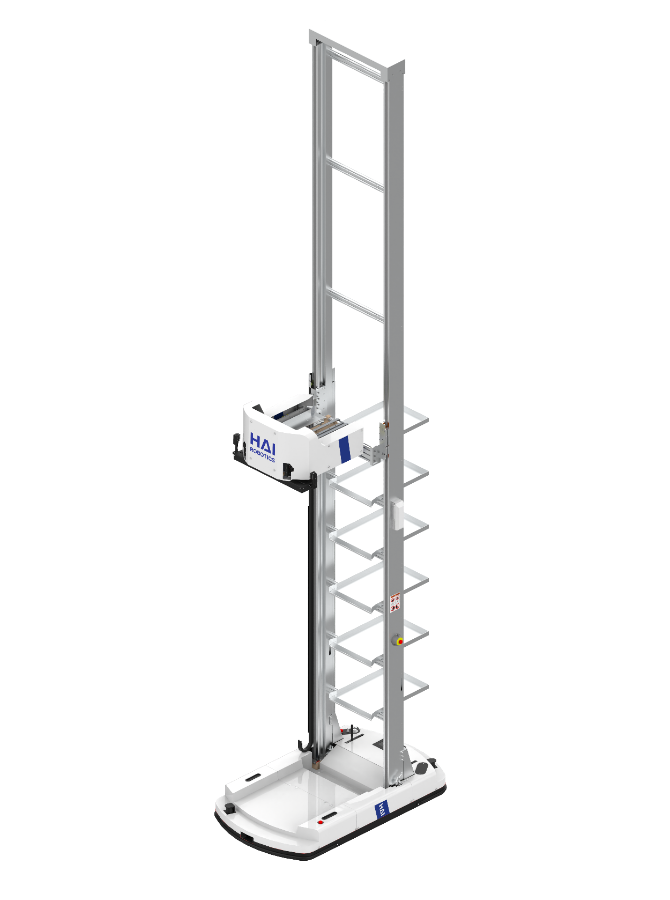

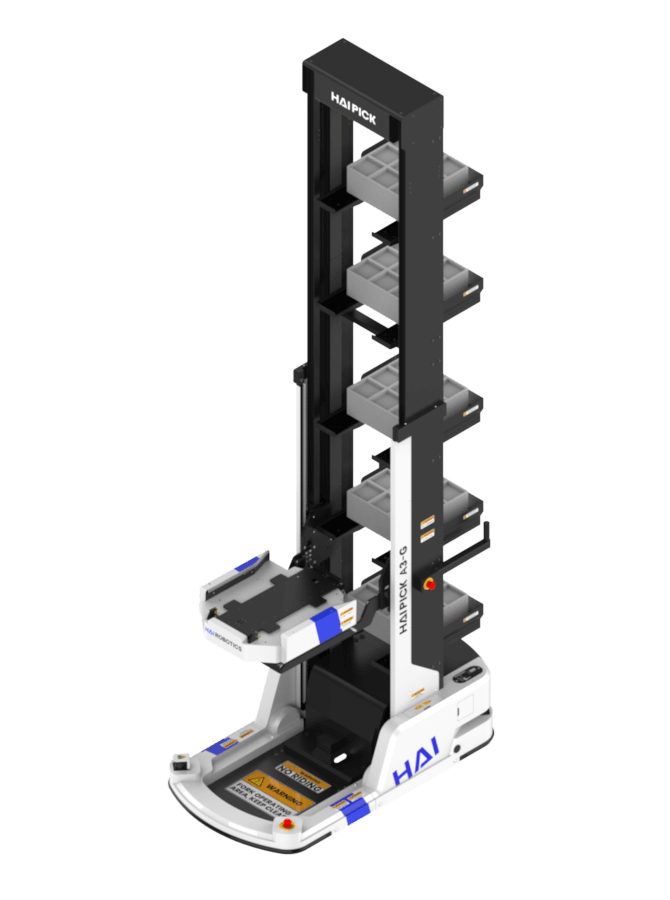

HaiPick A42

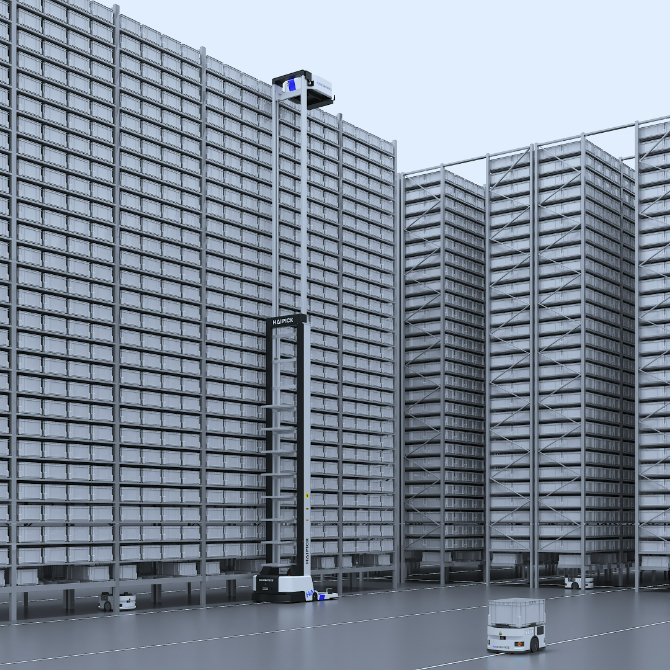

The A42-series offers picking and storage of cases up to a height of 6m (19.7 feet). The series consists of four models which handle a wide range of case dimensions and types. Compatible plastic tote and carton box in different sizes.

High Efficiency:

With multiple storage trays, our automated warehouse picking robot can handle up to 9 cases simultaneously. This greatly improves warehouse picking efficiency.

Flexible Payload Dimensions:

The robot supports separate and mixed picking of plastic totes and carton boxes. The robot can handle a wide range of case dimensions and types.

Flexible and Scalable:

Users can re-use existing racks and totes if they fit all requirements. Our automated warehouse picking system can also be easily deployed in a small part of the warehouse and scaled up to a bigger installation as the user's business grows.

Efficient Deployment:

Our robotic warehouse automation system can help you rapidly automate your warehouse without impacting any running operations.

Product Safety:

CE+NRTL certified.

The A42-series offers picking and storage of cases up to a height of 6m (19.7 feet). The series consists of four models which handle a wide range of case dimensions and types. Compatible plastic tote and carton box in different sizes.

High Efficiency:

With multiple storage trays, our automated warehouse picking robot can handle up to 9 cases simultaneously. This greatly improves warehouse picking efficiency.

Flexible Payload Dimensions:

The robot supports separate and mixed picking of plastic totes and carton boxes. The robot can handle a wide range of case dimensions and types.

Flexible and Scalable:

Users can re-use existing racks and totes if they fit all requirements. Our automated warehouse picking system can also be easily deployed in a small part of the warehouse and scaled up to a bigger installation as the user's business grows.

Efficient Deployment:

Our robotic warehouse automation system can help you rapidly automate your warehouse without impacting any running operations.

Product Safety:

CE+NRTL certified.

Product Features

Optional Custom Features

Optional Custom Features

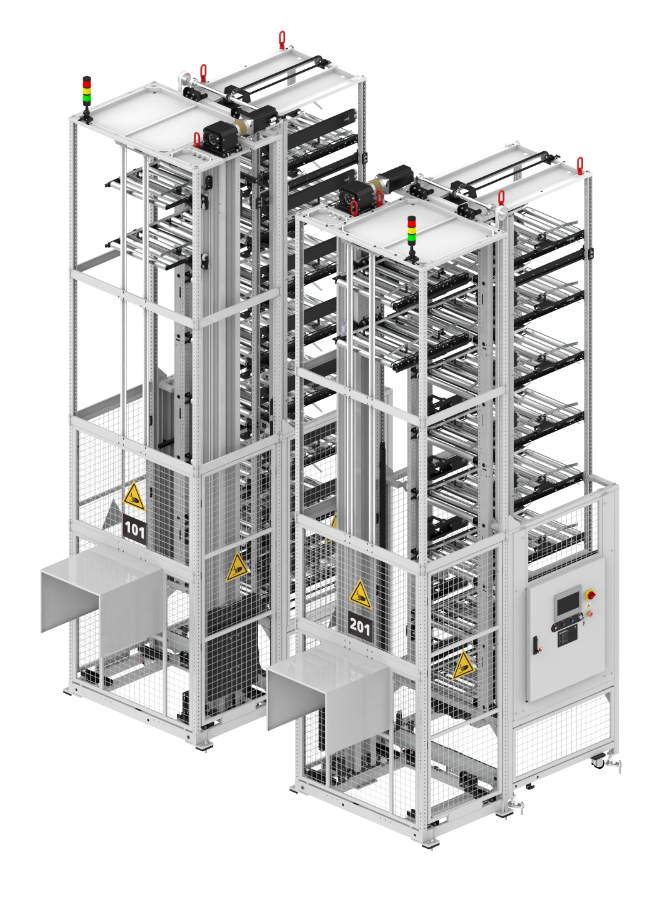

Double-deep Fork

Reduce aisle area by 50% and further increase storage density.

3D Visual Recognition

Support carton picking, compatible with multi-size cases.

Adapt to the situation that some containers cannot be identified by the code.

Flexible Width Fork Technology

The size of the cases can be automatically recognized for flexible pick and place.

Utilizing case spacing to increase the overall storage density by more than 30%.

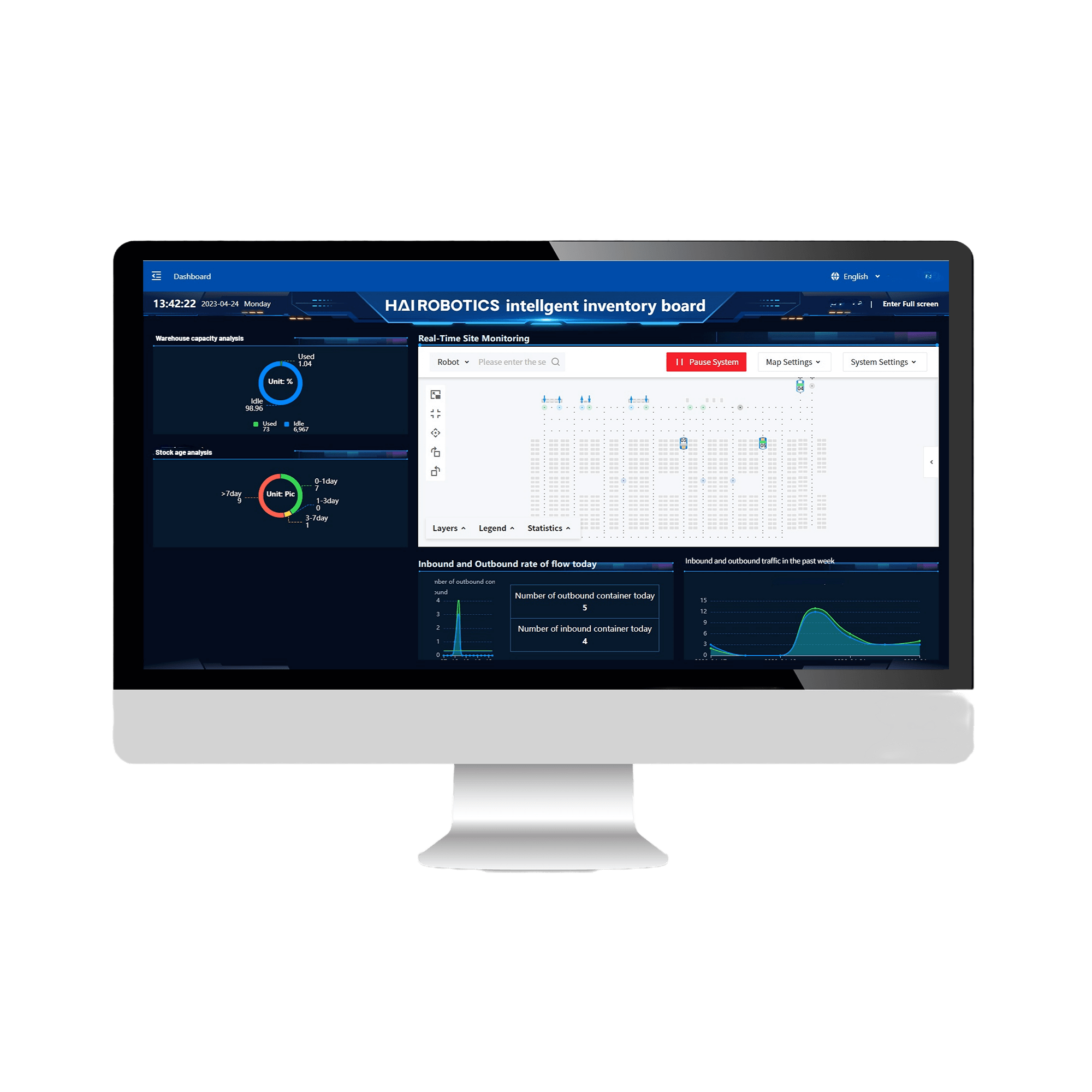

Increase storage density by 80-400% and space utilization rate.

Easy to expand, transform, and relocate, quick response to market demands, and business changes.

Increase operational efficiency by 3-4 times per worker, working accuracy 99.99%.

Support 2B, 2C, bonded warehouse, and other businesses to meet diverse needs.

Optimize operation procedures, improve storage efficiency, and shorten investment return cycles.

Flexibly respond to customized production requirements and facilitate efficient manufacturing.

Reduce operating costs and meet diverse production and industry scenarios.

Download Whitepapers & Brochures

Download our latest industry report and learn how ACR powers different sectors. You'll learn exactly what ACR is and why it's different and so powerful.

Download the white paper and discover what industry leaders think about the future of warehouse automation, the impact it would have on workforces and sustainability, the risks facing the industry, and the potential avenues for collaboration to drive forward progress.

If you are exploring ASRS solutions for your facility, know these 6 critical tips to help you identify the best solution for you. Discover tips to identify inefficiencies in your facility workflows and what to look for when exploring automated storage that can help you achieve the largest return.

If you're exploring automated storage and retrieval systems (ASRS) for your facility, understanding — and correctly calculating — your SKU batch factor will help you choose and design the right-sized solution, and save you from over- or under-buying what you actually need.