HaiStation

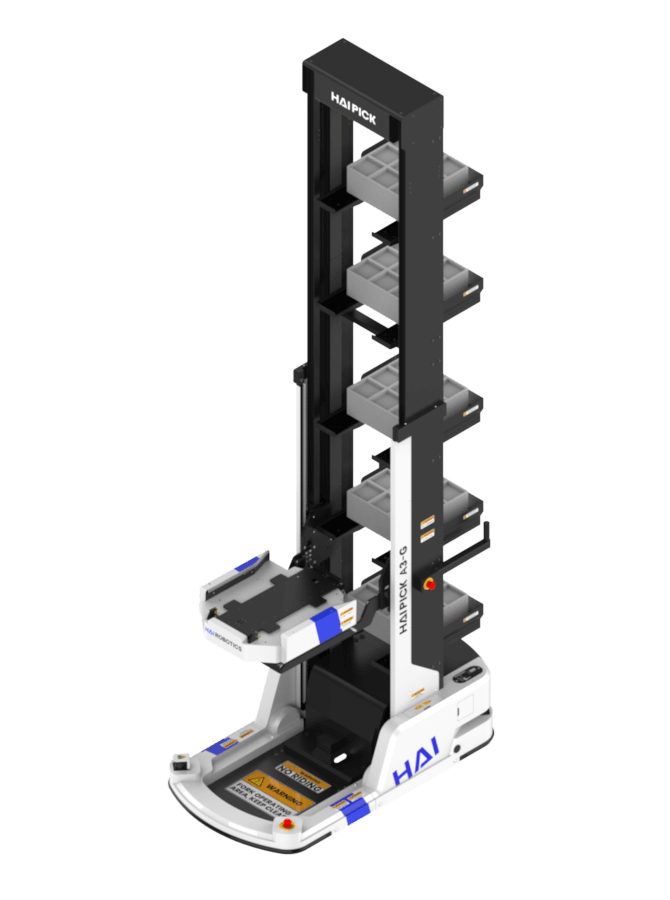

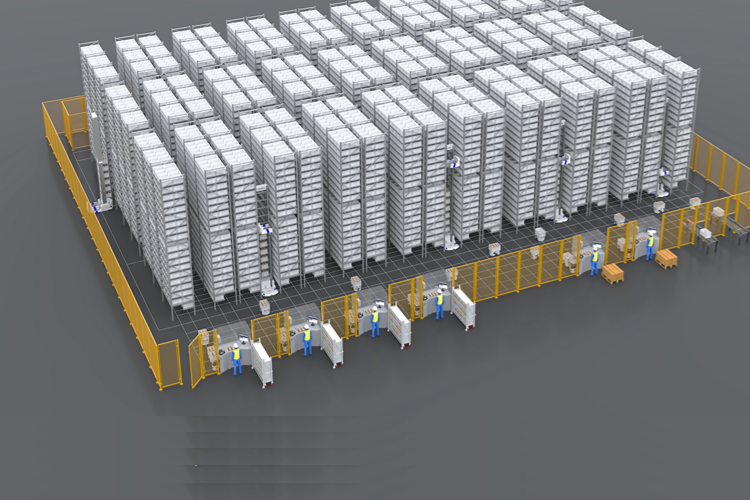

In the complete Goods to Person solution, HaiPick robots are dedicated to improving transport efficiency from warehouse to workstation. Hai Robotics also developed HaiStation, which is used to improve the efficiency of workstations to order cases.

HaiStation is a product portfolio that is composed of including HaiPort, conveyor, put wall, buffer wall, workstation, robotic arm, etc. As the backend of the whole warehouse solution, HaiStation provides ultra-efficient case loading and unloading connections to frontend robots with safe human-robot interactions.

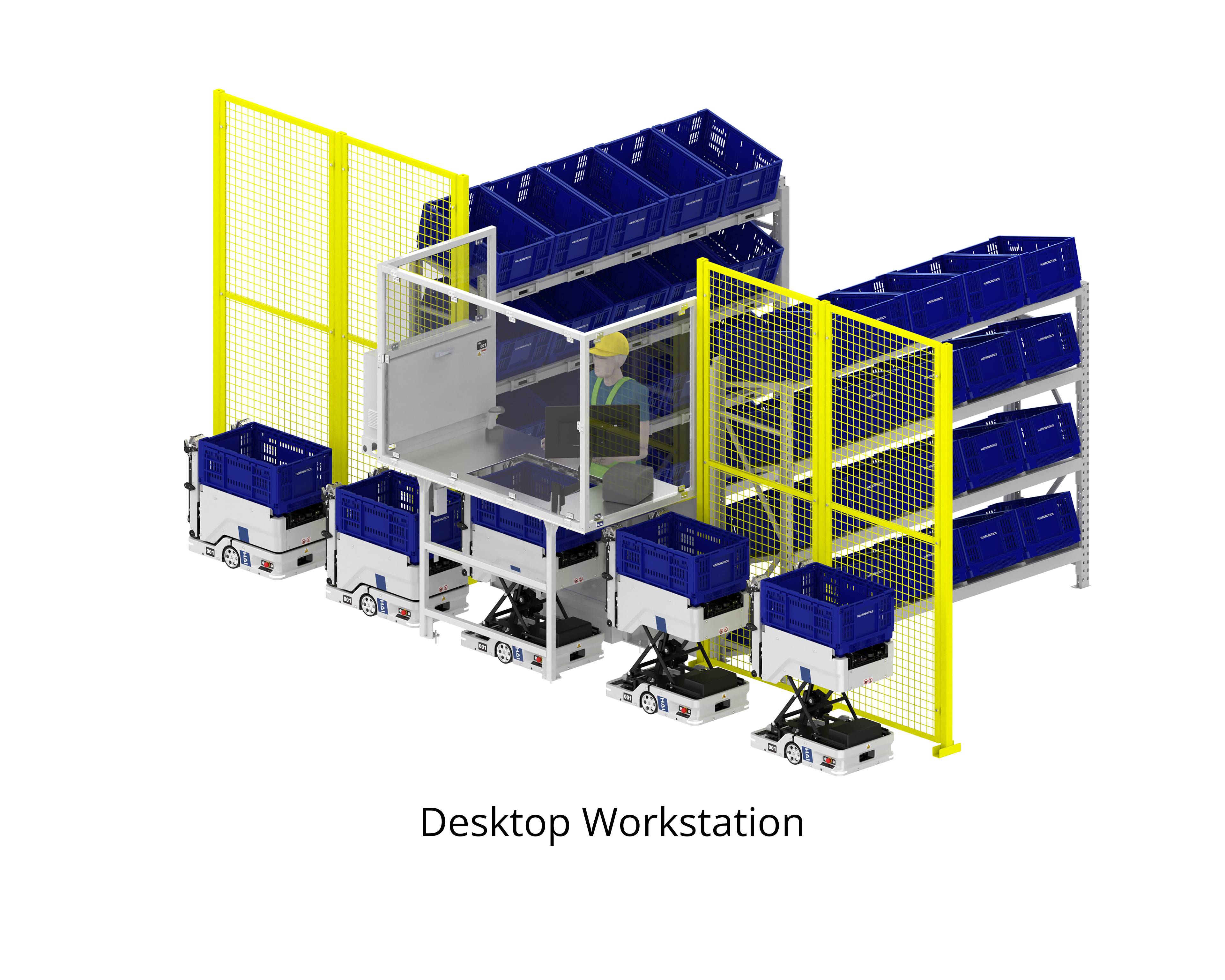

Desktop Workstation

The desktop workstation launched by Hai Robotics specifically configured for HaiPick System 3, collaborates with ACRs and AMRs to facilitate safe and efficient business operations. Besides, the use of automatic double doors reduces hand injury risks, ensuring personnel safety.This product is designed with an integrated structure for easy installation, featuring picking locations that conform to ergonomic standards to ensure utmost comfort for the workforce. The workstation, primarily used for outbound operations, is equipped with more user-friendly human-robot interaction (HRI) and enhanced system security.

- On-robot Picking

Direct collaboration with AMRs, requiring no additional picking and transferring.

- High Flexibility

Easily transported by using a pallet jack for fast, convenient relocation.

- High Safety and Reliability

Equipped with integrated supporting legs and structural designs including upper protective fence, automatic double doors, ensuring safe and reliable operations.

- User-friendliness

Well-designed height, conforming to ergonomic standards to ensure utmost comfort for the workforce.

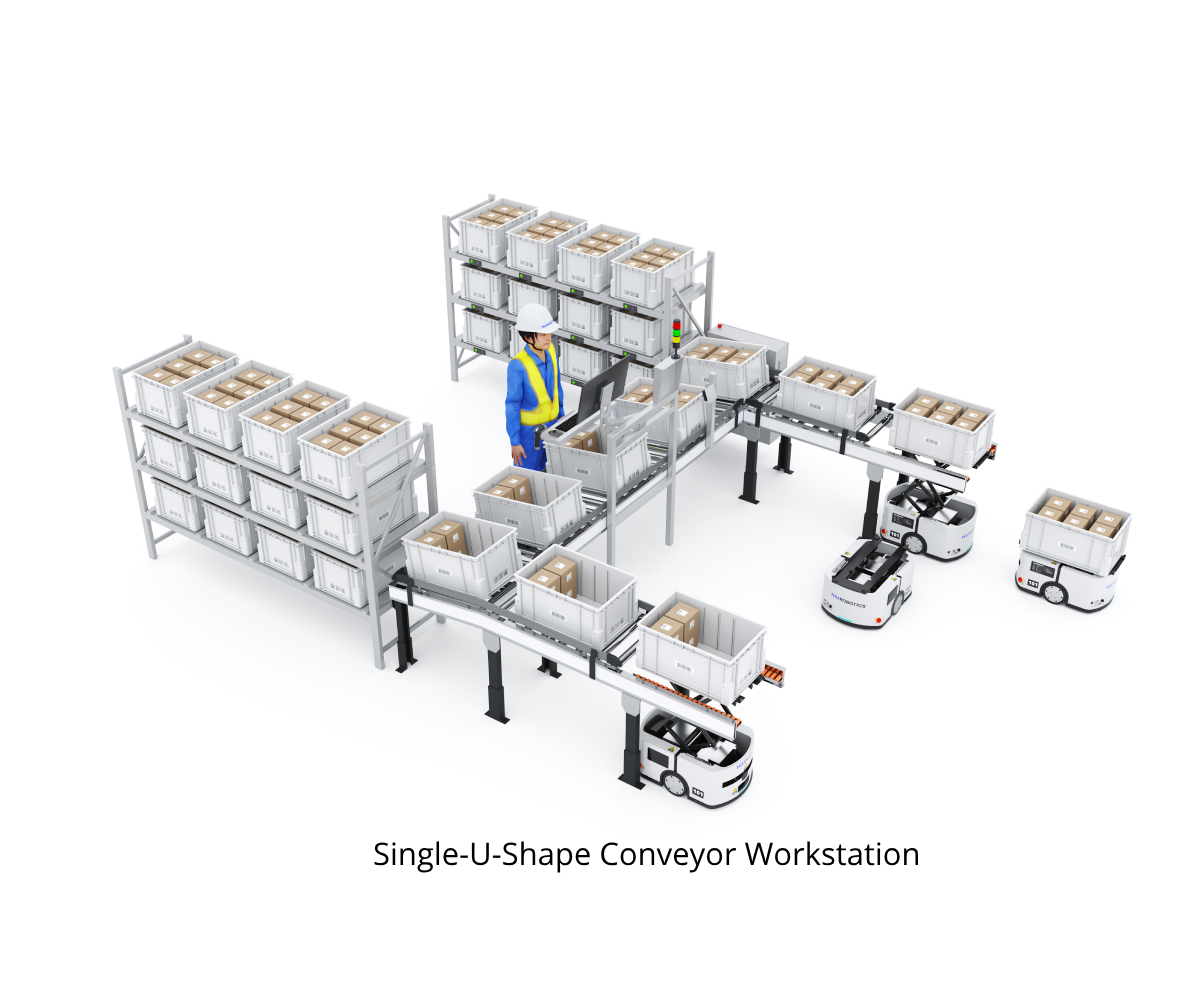

On-conveyor Picking Workstation

The on-conveyor picking workstation automatically conveys the cases unloaded by the HaiPick robot or the cases that need to be loaded, realizing automated storage and retrieval functions. It is composed of a conveyor line, visual Kanban, shelves, and pick to light system.

It offers an ergonomic design, the workers and HaiPick robots are indirectly connected, and the goods can be sorted on the conveyor line without too much movement. It delivers convenient operation and efficient warehousing.

Intelligent Sorting

The visual system Kanban manages work, guiding workers to sort goods more efficiently.

Easy to Operate

The worker can finish picking goods on the conveyor line without walking or moving.

Safe & Comfortable

Ergonomic design that allows safer and comfortable operations.

High Efficiency

Each robot can transport 25 – 30 cases/h for inbound operations and 25 – 30 cases/h for outbound operations, and the maximum efficiency of a single workstation can reach 300 cases/h.

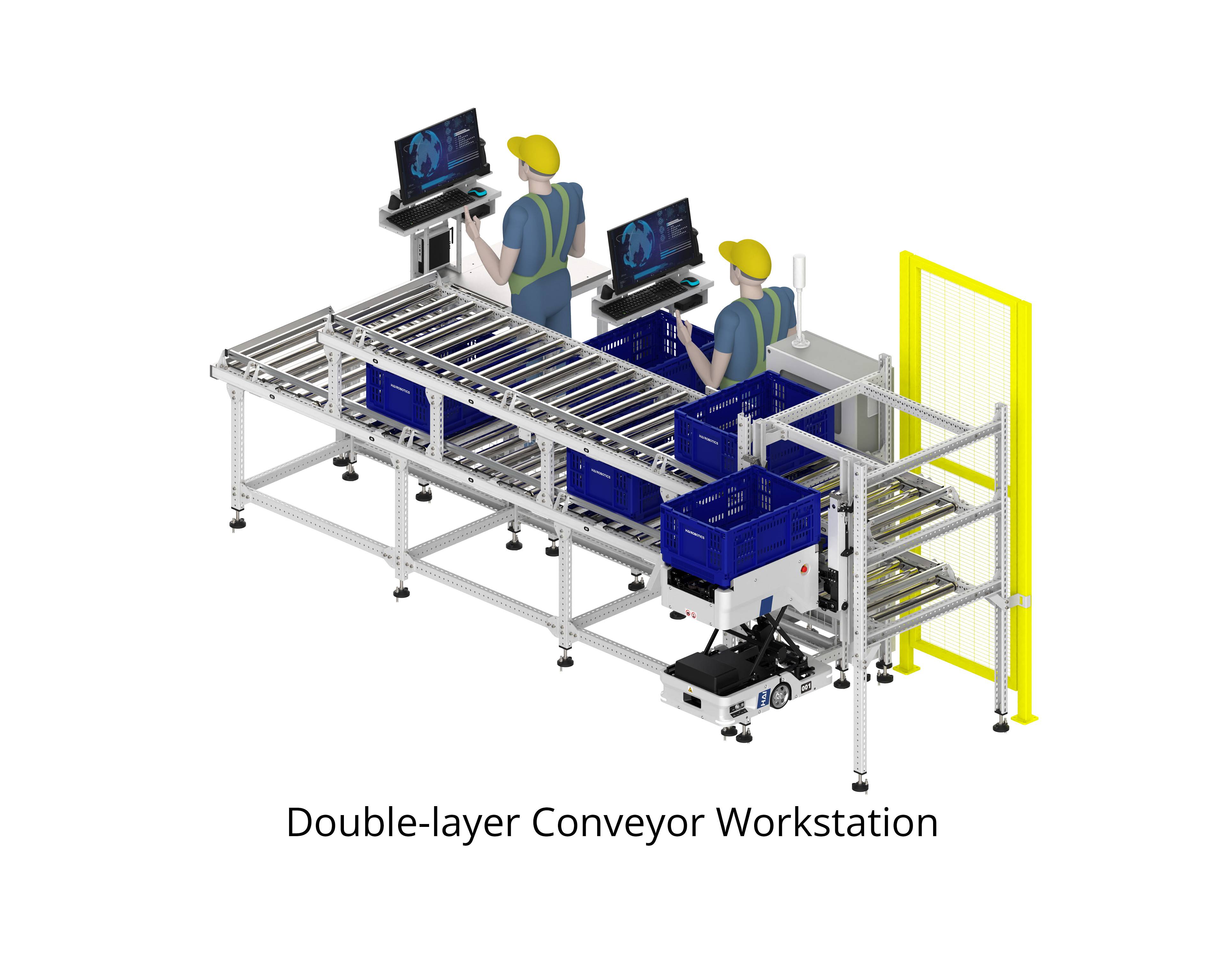

Double-layer Conveyor Workstation

The Double-Layer Conveyor Workstation is a cutting-edge solution designed for the HaiPick Climb system to optimize inbound operations. Featuring a dual-level conveyor system, this workstation enables HaiClimber robots to deliver empty totes and retrieve full totes for inbound in one trip, increasing inbound efficiency.

-

Automated Inbound Process

HaiClimbers can autonomously exchange empty and full containers in a single trip, streamlining the inbound process and reducing manual handling.

-

Optimized Ergonomics

The workstation provides an ergonomic picking process, minimizing worker strain, improving accuracy, and reducing errors.

-

Flexible and Scalable

The modular design allows for easy expansion and customization to accommodate versatile needs.

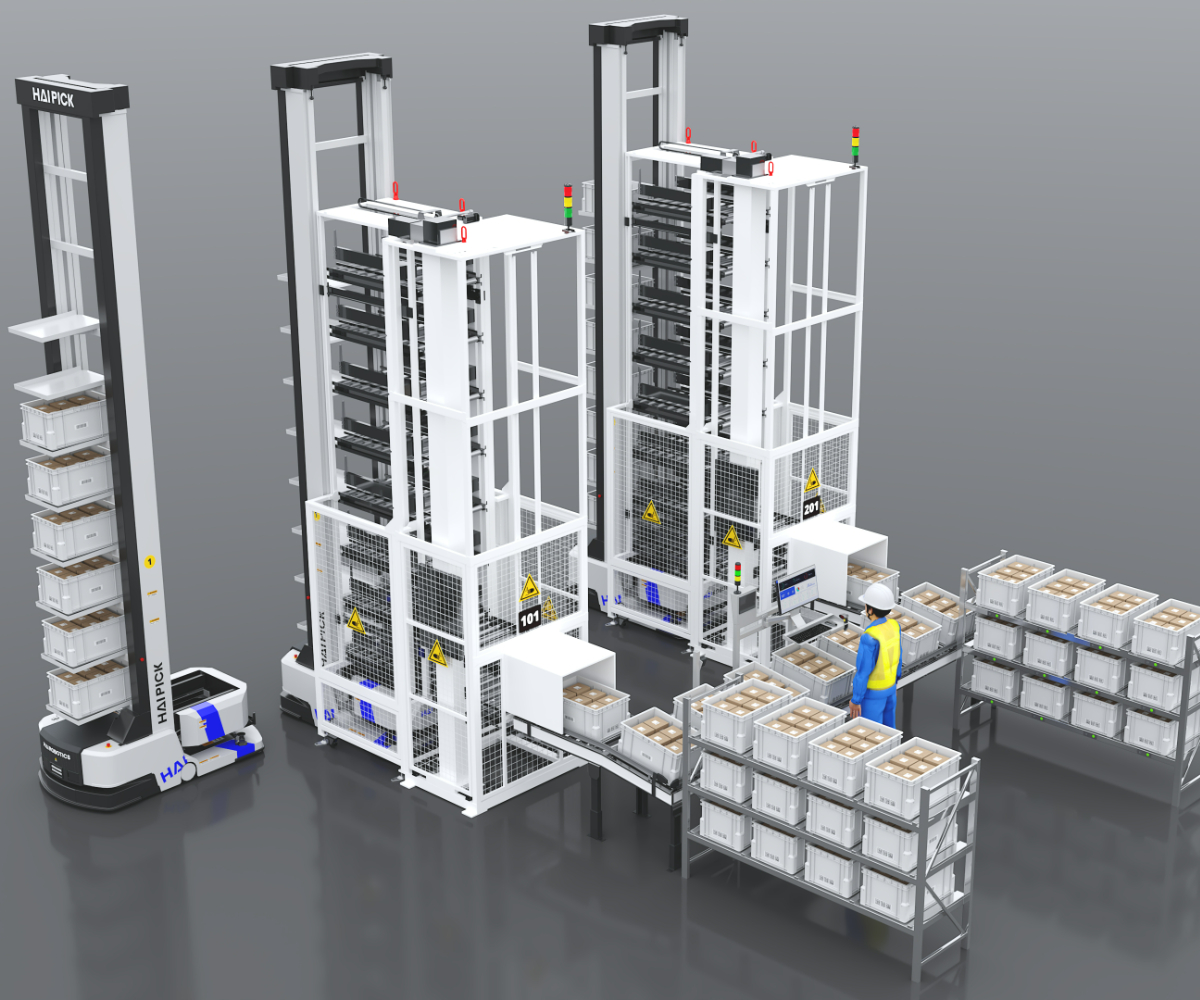

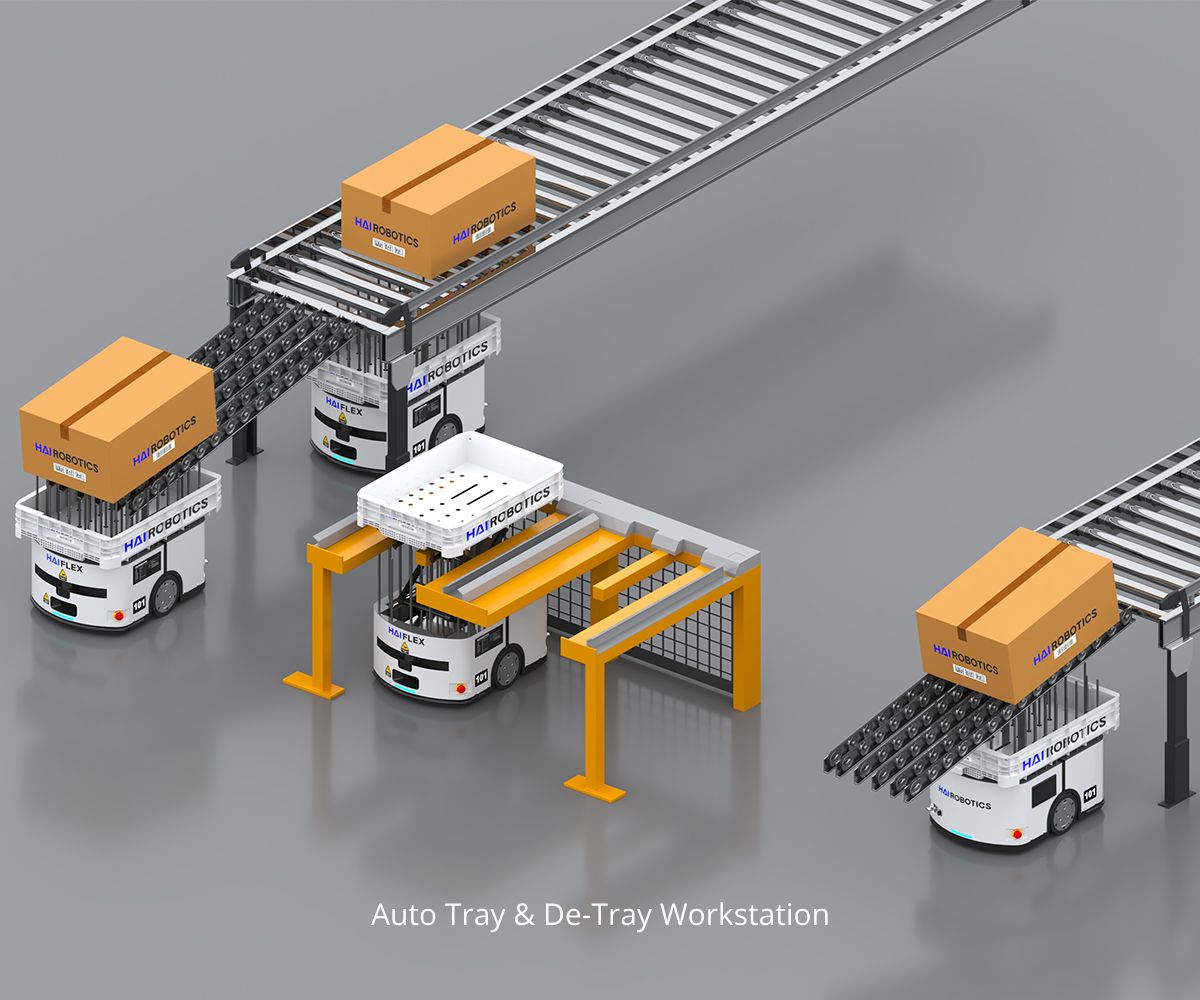

Auto Tray & De-Tray Workstation

The automated Tray and De-Traying workstations allow inventory to be automatically entered into the HaiPick System. Goods are scanned in and placed on the conveyor where it is automatically placed onto a tray on Companion Bot and stored into the HaiPick System. Inventory is just as easily automatically removed from the trays when they return to the workstation for order fulfilment.

This workstation allows facilities to easily automate the management of medium size irregular inventory, inventory with varied packaging, or other kinds of diverse inventory that needs to be automated together.

- Automated Storing Prep

Inventory is automatically placed on a tray for them to be processed in the HaiPick System. Goods are automatically removed from the tray when they return to the workstations for order picking.

- Full case in - Full case out

Ideal for stores and facilities with larger fulfilment quantity needs, full cases of inventory can be automatically stored and retrieved.

- Irregular Goods Management

Goods with varied sizes, packaging, or container types can be automatically stored and managed together in a single system.

- Removes Heavy Lifting

For industries including Food and Beverage and Manufacturing that often manage heavy cases and cartons of goods, inventory is brought to an ergonomic height to minimize lifting and twisting to maneuver the inventory.

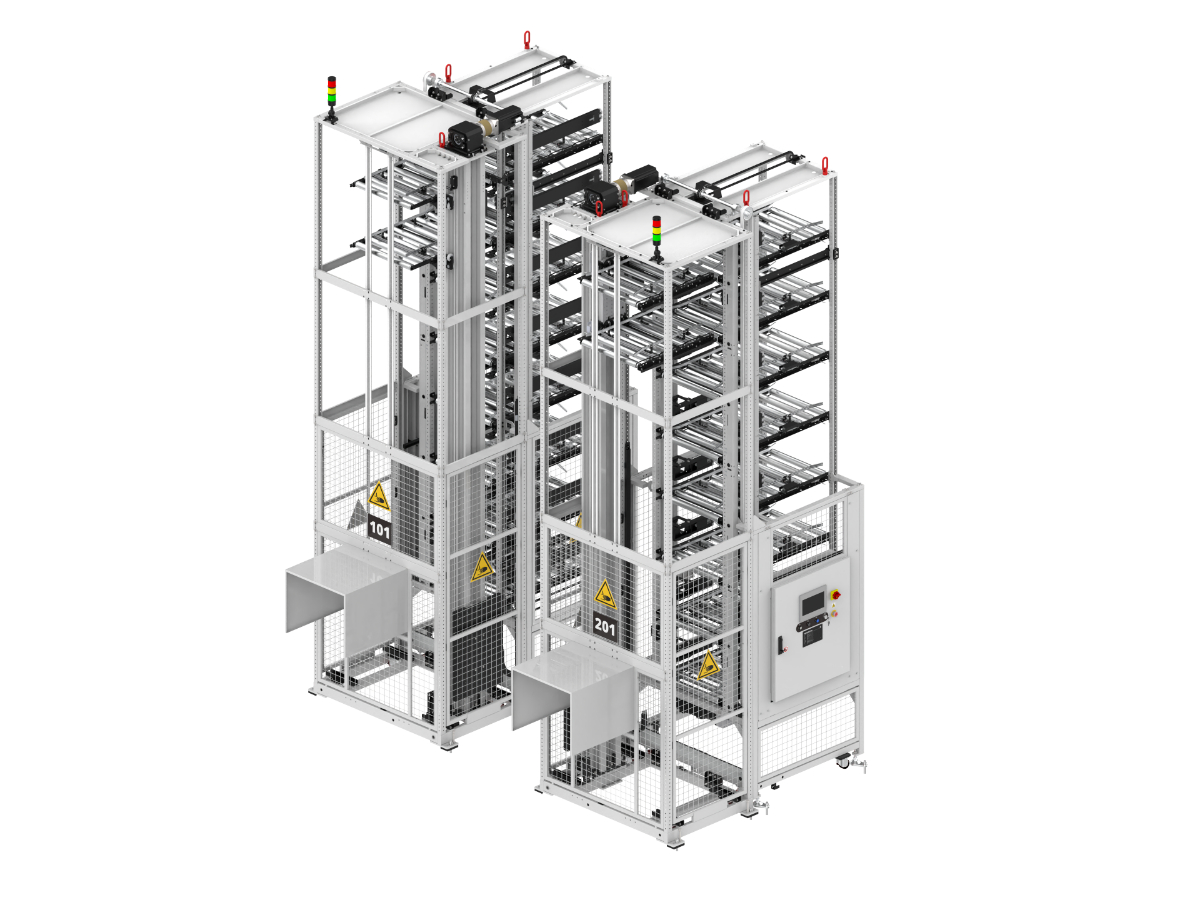

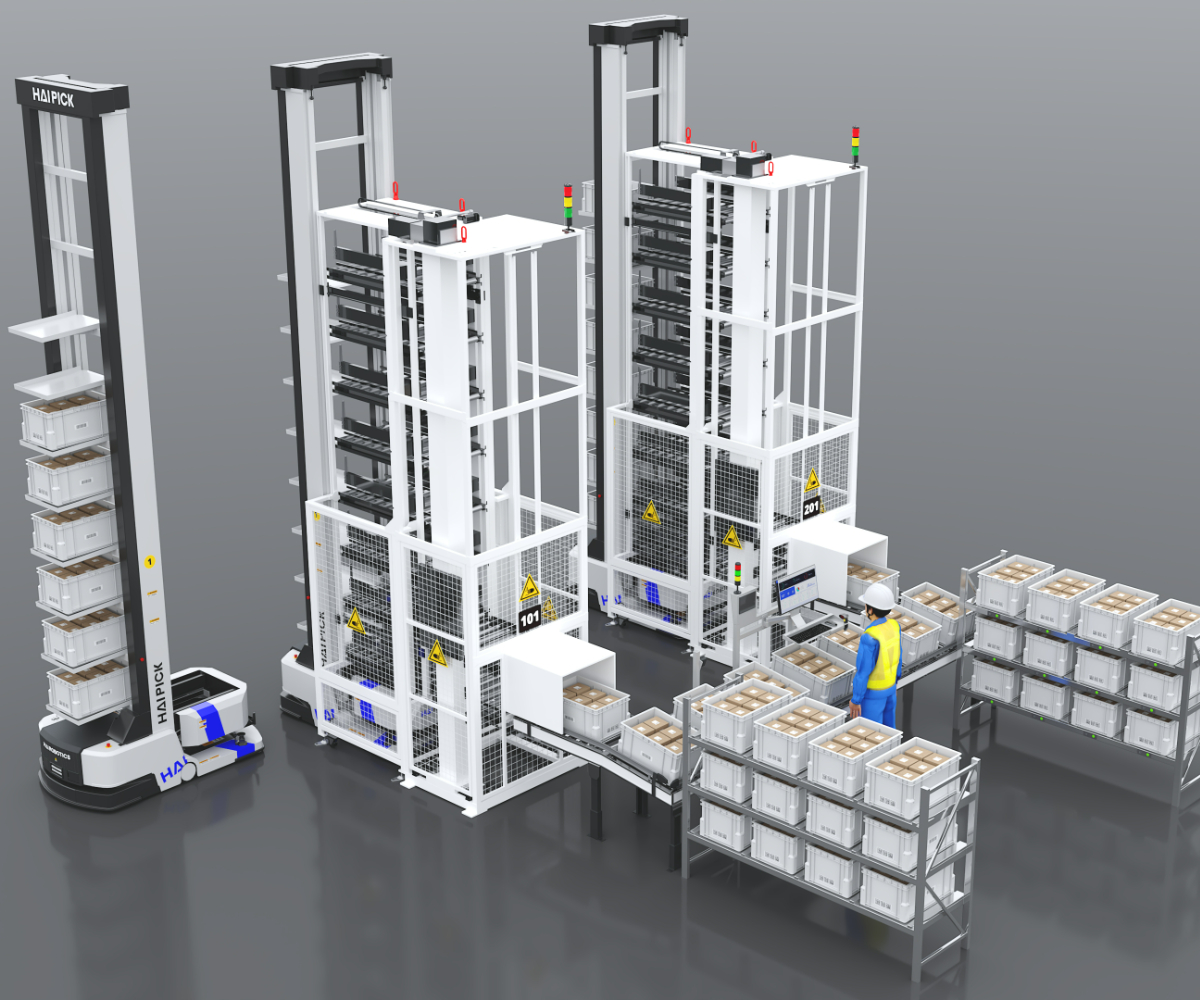

HaiPort-powered Workstation

HaiPort-powered workstation is an automatic loading and unloading machine. It is composed of HaiPort, conveyor, visual Kanban, put wall, pick to light system, and can easily dock with HaiPick ACR to automatically unload, transport, and load cases from the robot's storage tray, optimizing inbound and outbound processes.

The workstation enables more efficient loading and unloading of cases. It can load 8 cases in 3 seconds and unload 8 cases in 5 seconds, which significantly increases HaiPick ACR's efficiency.

Its modular design, flexibility, and easy transport capabilities support rapid increase/decrease of equipment, meeting high efficiency and low cost requirements. Workers and storage robots are separated to ensure safety. The ergonomic design of the on-robot picking workstation delivers convenient operation, high efficiency, and low cost.

High Efficiency

Handles up to 8 cases at once – fully loading / unloading handoffs in seconds.

Best and Fastest

Loads 8 cases in 3 seconds, unloads 8 cases in 5 seconds.

Human-robot Cooperation

With an ergonomic design, HAIPICK robots and workers are indirectly connected.

400% Faster

Reduced loading and unloading time by 80%.

Efficient Deployment

Modular design ensures easy deployment and redeployment when changing warehouse workstation layouts.

Product Safety

CE /NRTL certified.

Download whitepapers and brochures

Download the white paper and discover what industry leaders think about the future of warehouse automation, the impact it would have on workforces and sustainability, the risks facing the industry, and the potential avenues for collaboration to drive forward progress.

If you are exploring ASRS solutions for your facility, know these 6 critical tips to help you identify the best solution for you. Discover tips to identify inefficiencies in your facility workflows and what to look for when exploring automated storage that can help you achieve the largest return.