HaiPick System 1

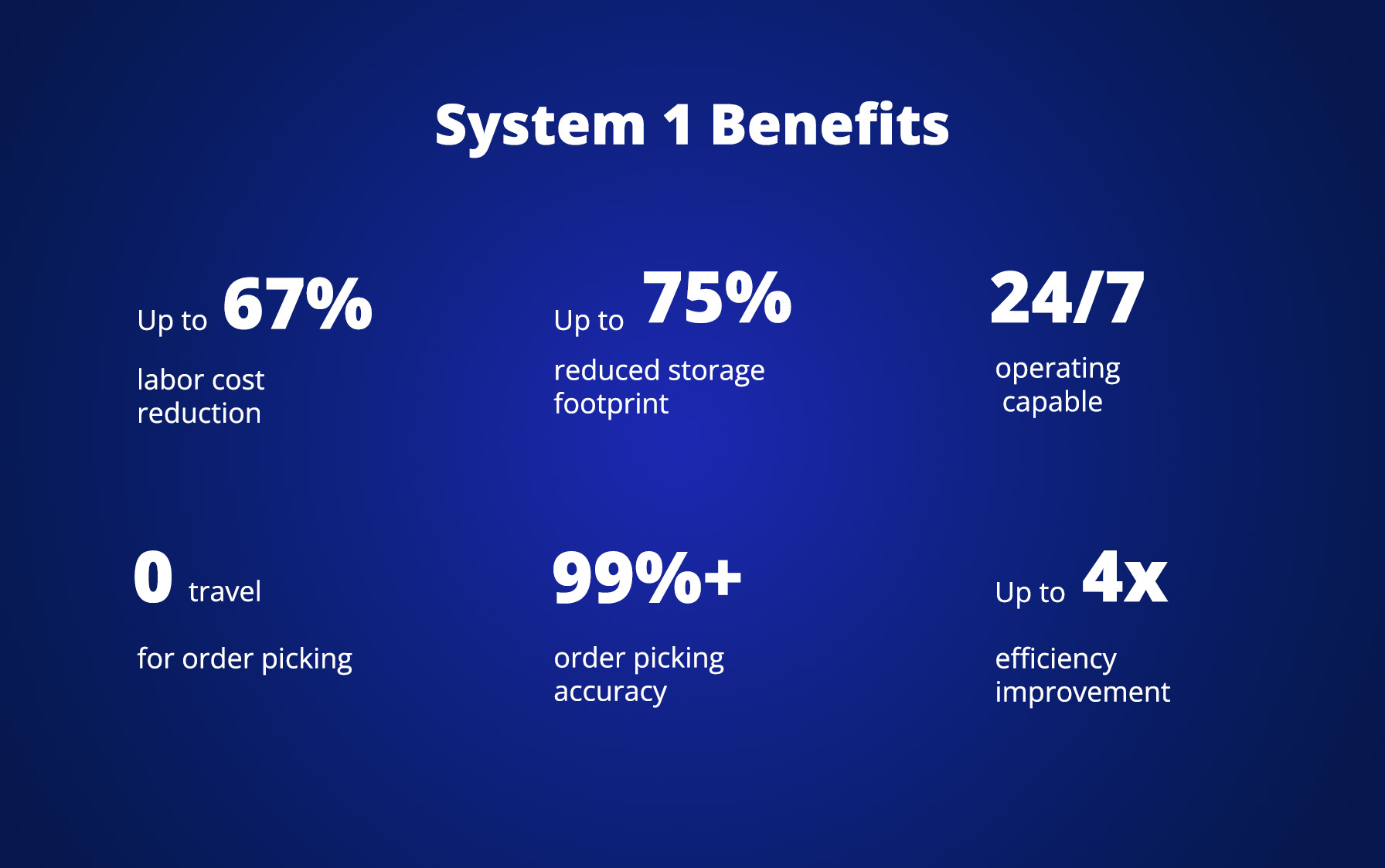

Our core goods-to-person solution, HaiPick System 1 is a versatile and scalable Automated Storage and Retrieval System (ASRS) designed to optimize warehouse operations by maximizing storage density, increasing order throughput, and reducing labor costs by up to 67%.

System 1 leverages advanced Autonomous Case-handling Mobile Robotic (ACR) technology to achieve 99%+ order picking accuracy and enables fast, efficient order fulfillment with seamless integration into existing facilities and warehouse management systems.

How It Works

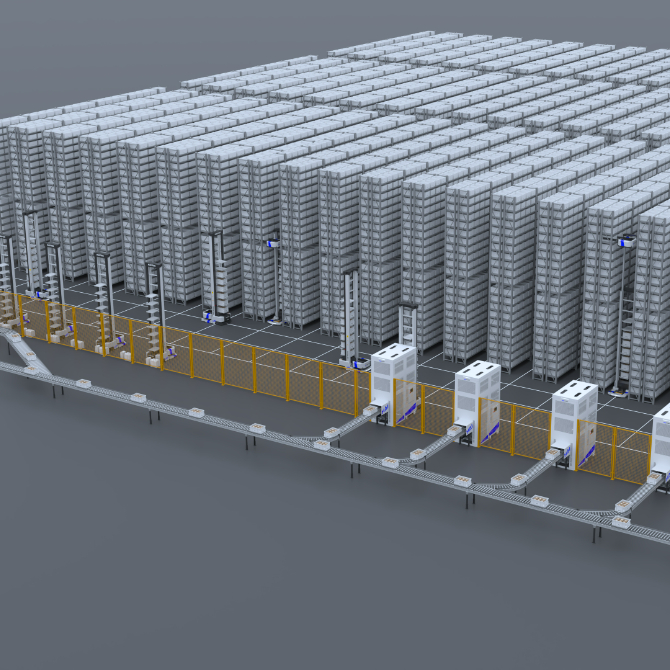

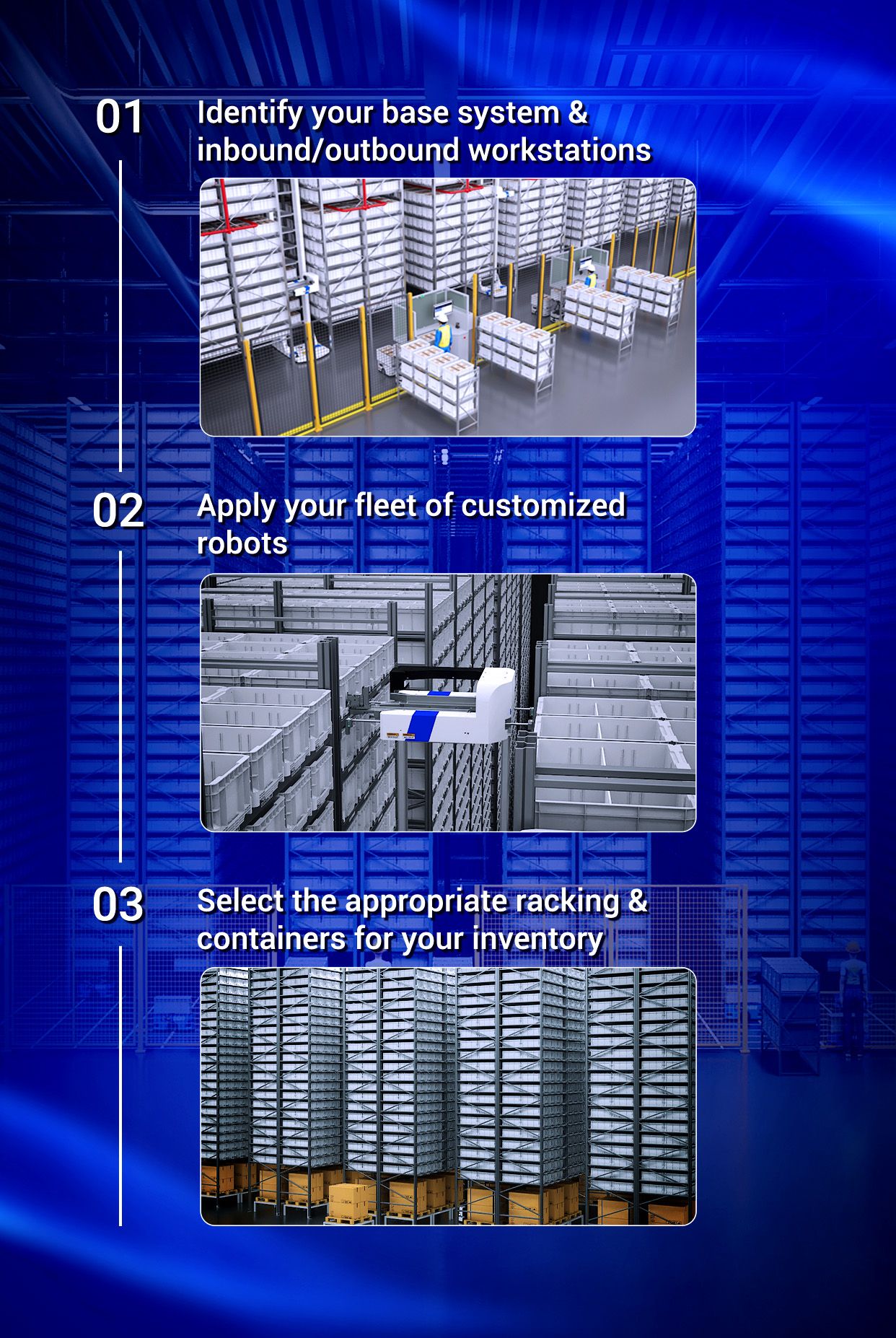

Each HaiPick System is a modular solution built from a range of components designed to fit your facility’s needs without the cost or complexity of fully custom automation.

In System 1, Autonomous Case-handling Mobile Robots (ACRs) strategically navigate confined storage zones, reaching up to 12 meters (39+ feet) high and 2 totes deep to transport inbound and outbound goods for storage and fulfillment. ACRs can batch deliver up to 9 containers simultaneously to a human-operated picking station, boosting workflow efficiency up to 400%.

System 1 elements include:

- HaiPick Autonomous Case-handling Mobile Robots (ACRs)

- Inbound/outbound workstations

- Industry-standard racking or shelving

- Any container, or no container for appropriate applications

- HaiQ software

The Robots

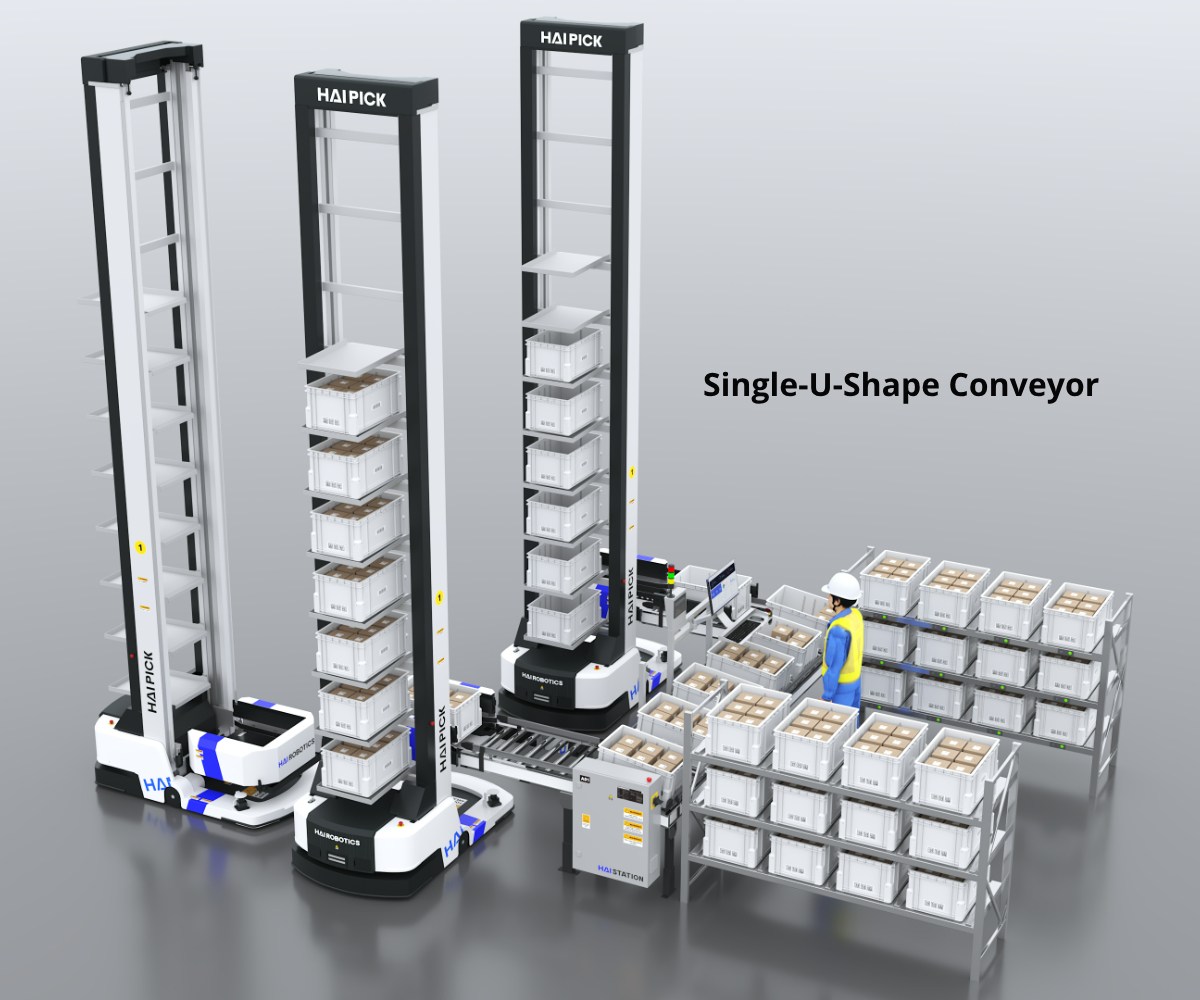

Our Autonomous Case-handling Mobile Robots (ACRs) are designed to operate seamlessly with nearly any industry-standard racking and containers within a HaiPick System — enabling versatile and cost-effective goods-to-person operations.

Unlike traditional Automated Storage and Retrieval Systems (ASRS) that require high-precision environments, HaiPick ACRs offer the freedom to store various container types and materials, reducing storage costs and increasing flexibility. In System 1, products can even be stored without containers.

Each robot is equipped with features tailored to the specific inventory it handles. Additionally, various models of ACRs can be employed within System 1 to enhance operational capabilities.

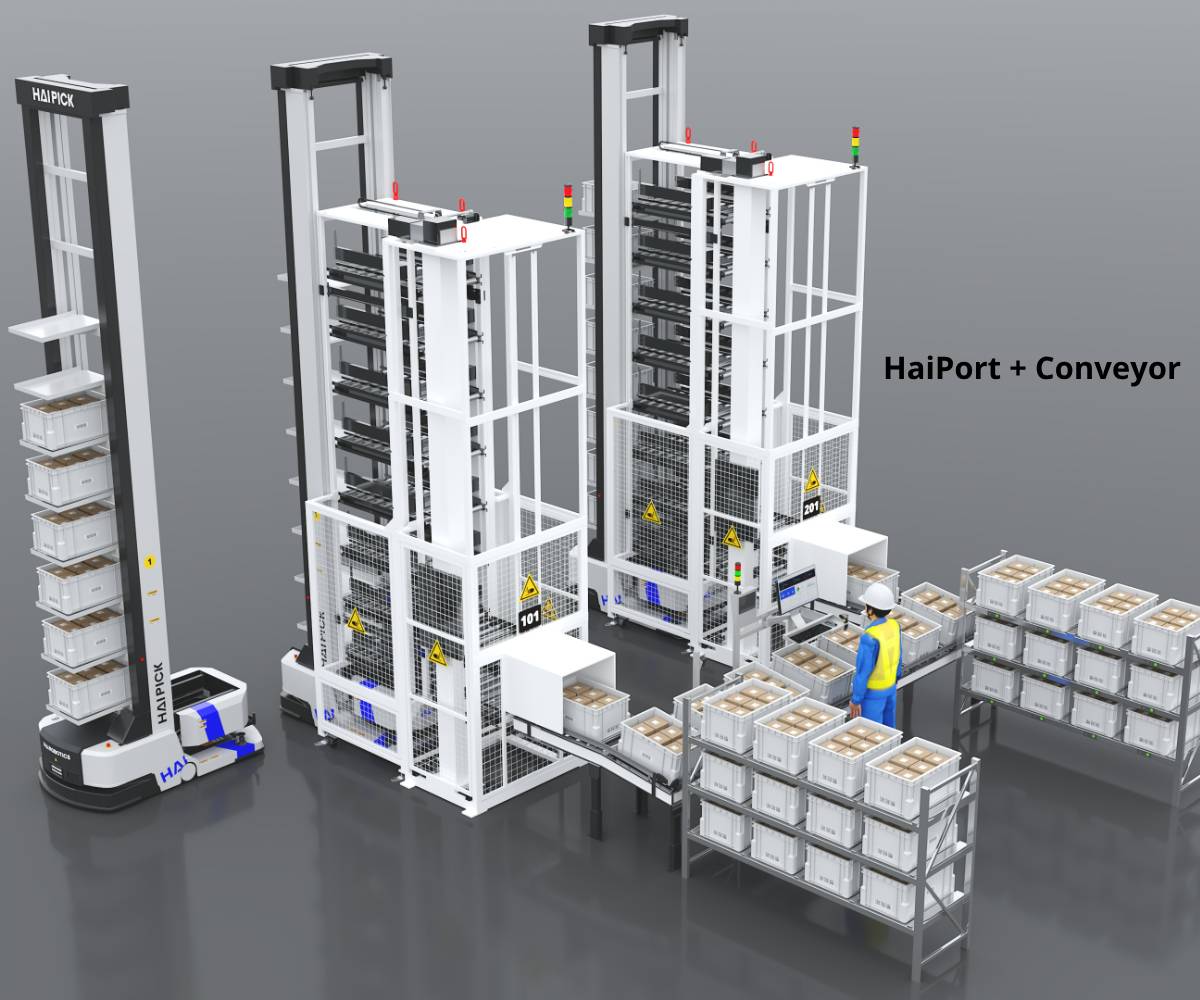

The Workstations

HaiPick Systems are accessed via workstations where inbound and outbound inventory is picked up and delivered by HaiPick Robots. Ergonomically designed, all workstations deliver a 99%+ order pick accuracy rate and can be tailored to maximize workflow efficiency and throughput, or facilitate seamless handoff to other technologies and operations.

Eliminate Human Travel for Order Picking

HaiPick Systems bring containers directly to operators, cutting out travel time for order picking and speeding up fulfillment.

Variable Workstations

Each HaiPick System can connect to different types of workstations operating simultaneously, supporting various workflows within a single system.

Lineside Delivery

HaiPick Systems deliver containers for manufacturing, kitting, and other processes through lineside delivery, conveyor systems, or other technology handoff points.

Safety

CE and NRTL certified.

HaiQ Software

HaiPick Systems can integrate seamlessly with almost any existing Warehouse Management System (WMS) or Warehouse Execution System (WES). HaiQ Software provides clear digital insights into inventory counts and details, optimizing robotic pathways to minimize travel and maximize order pick speed and efficiency.

Racking & Containers

HaiPick Systems are compatible with almost any industry-standard racking and shelving. Our HaiPick Robots are built to work within real-world tolerances, providing flexibility to manage inventory automatically without the limitations of traditional Automated Storage and Retrieval Systems (ASRS).

Any Rack

Most HaiPick Systems can operate with various types of racking, not requiring a specific type. Non-intelligent and non-mobile system elements can be chosen based on application needs, preferences, and budget.

Any Container

HaiPick Systems are material-agnostic and can handle a wide range of containers, including totes, trays, cardboard boxes, styrofoam, metal baskets, and others of varying sizes.

No Container

For products that are appropriately sized and consistent, using a container may not be necessary.

What Makes a HaiPick System

Explore Your HaiPick Design

To explore how a HaiPick System can advance your facility and connect with a local system engineer with experience in your industry, try our Solutions Generator.