Empowering the Warehouse with Innovative Robotics Solutions

With CeMAT Sydney just around the corner, here is all you need to know about the latest innovative and intelligent robotics solutions being showcased by Hai Robotics Australia team.

Hai as an organisation consistently strives to progress human civilization using robotics technology, and the latest products in its growing portfolio underpin this philosophy.

Since our inception in 2016, Hai Robotics has become a pioneer and leader in intelligent robotics solutions. As the world’s first company to launch an autonomous case-handling (ACR) system, the organisation is a leader of innovation and committed to designing products that help revolutionise and transform the warehouse.

Boasting more than 1,600 employees worldwide, more than half of which are engineers – Hai Robotics has completed over 1,000 projects for world-leading organisations in fashion, 3PL, retail, electronics, healthcare and e-commerce. As the first to enter the ACR market, Hai has also retained its status as the world’s leading provider of ACR systems.

After recently launching in Australia, Hai Robotics is gaining significant traction in the ANZ market and has quickly become a name synonymous with growth, expansion and future demand readiness for the Australian logistics landscape.

Australian distribution centres are frequently subject to operational workflows that are impacted by the extreme sizes of items in a typical e-commerce order. Many organisations are using archaic and loosely designed workflows to address orders that contain a combination of bulky and heavy pallet-based items, along with smaller tote-based items. This is extremely hard to address and leads to a high cost to serve.

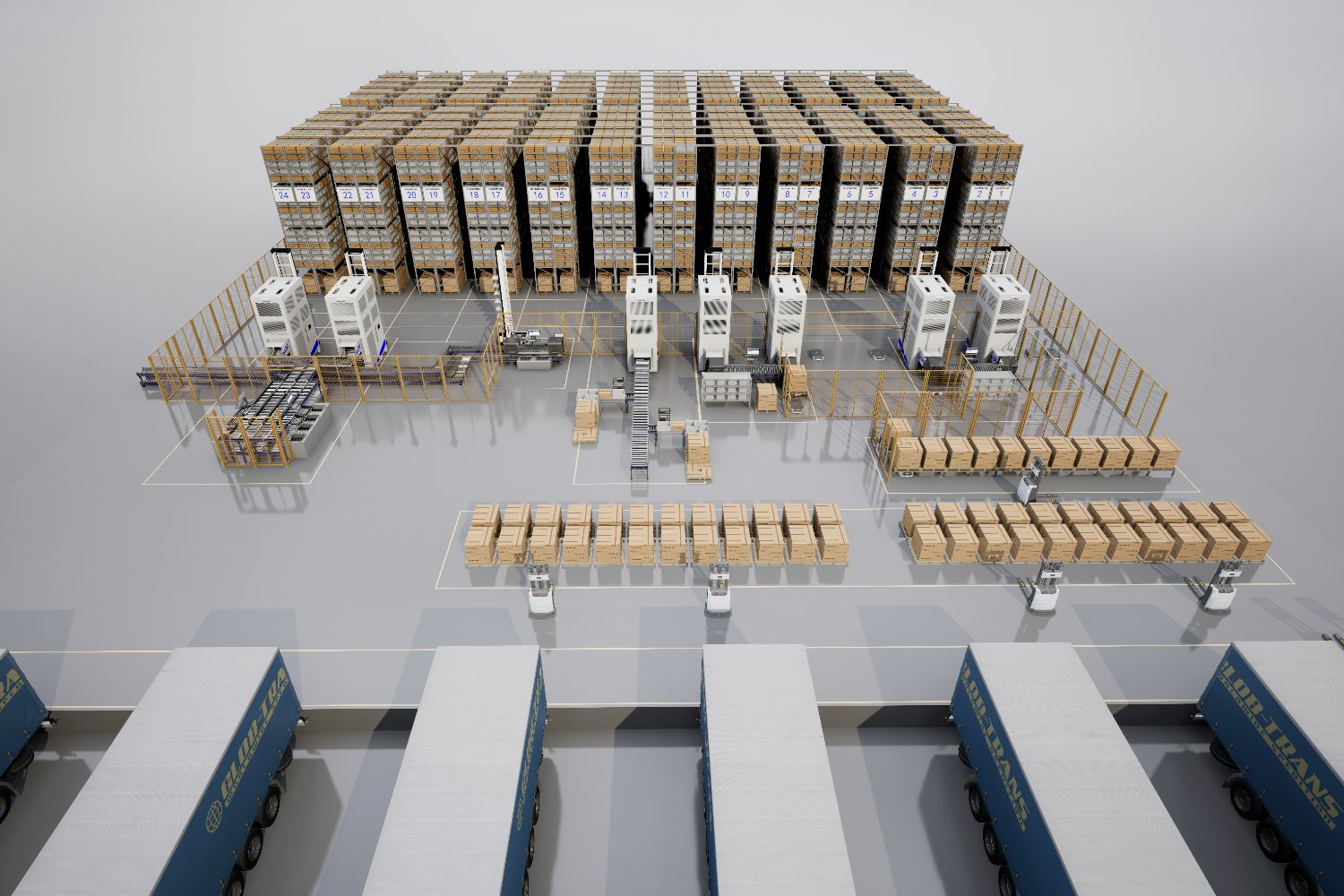

With the profile of e-commerce orders more diverse than ever, Hai Robotics has launched a new solution that can combine both pallets of product, and totes and cartons.

The new combined solution encompasses Hai’s standard HaiPick solution, along with the AMR-led solution, HaiFlex within the same operational grid. It allows a customer to pick both smaller items from a tote, as well as bulkier items from the AMR. For example, one order may contain pet food – which might weigh 20kg, but there may also be smaller items such as treats, pet collars etc. This new solution provides the flexibility to pick both of these items using the same automated solution.

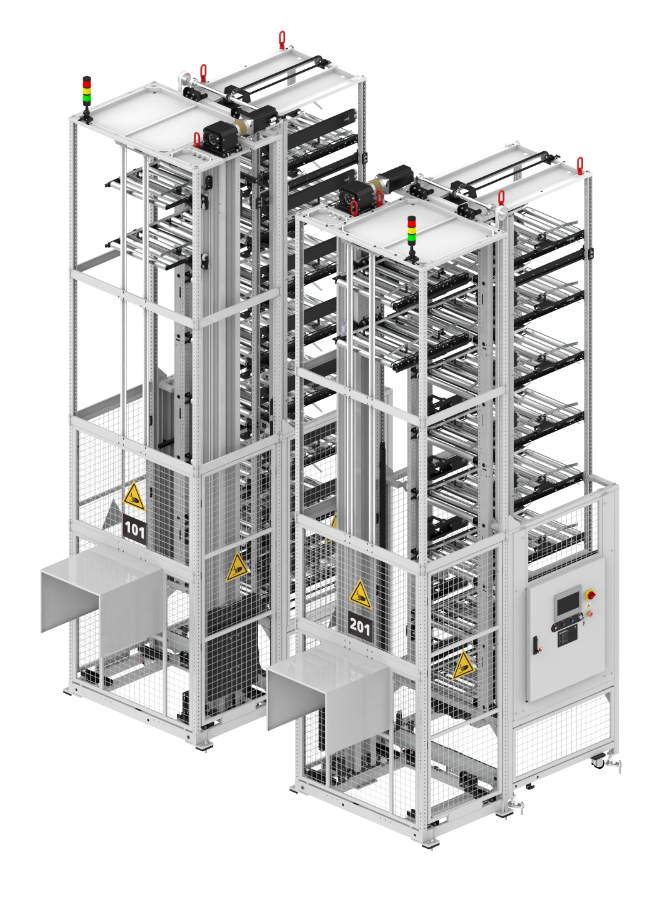

With the price of storage and industrial property at an all-time high, being able to increase density enables organisations to make better use of storage space.

Double deep tote storage is of particular interest to the ANZ market at the moment, when we’re seeing record rent prices and a severe shortage of available industrial property organisations are having to think of innovative ways to maximise their footprint.

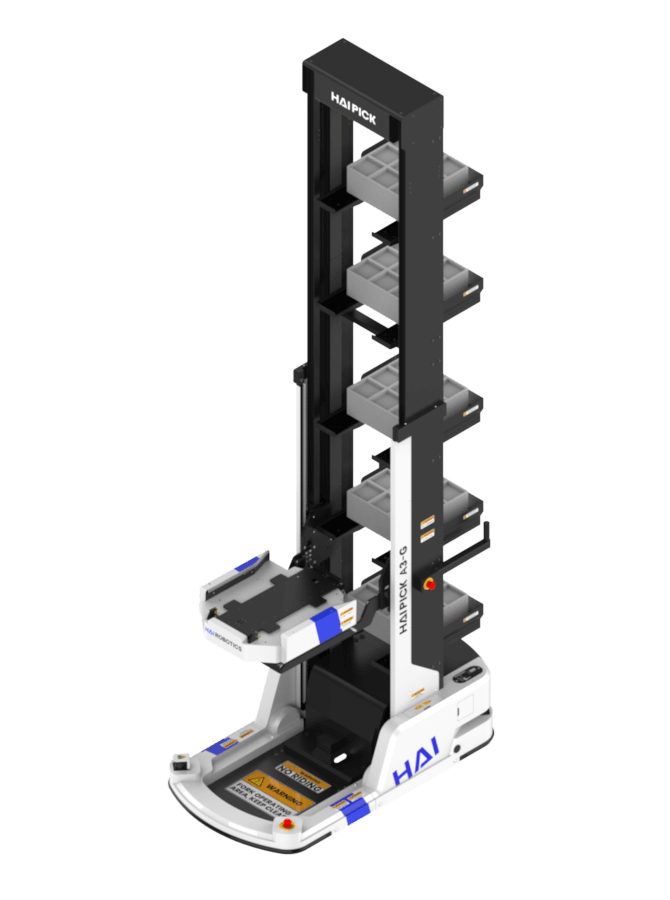

The combined power and capabilities of Hai’s popular HaiFlex AMR and the HighPick ACR addresses the need to pick and pack a combination of bulky items that are typically larger than a tote size, as well as smaller SKUs which are typically tote-sized items. In fact, the HaiPick ACR is now also available in a taller format achieving a height of up to 10m called HaiPick A42TD.

This combined automated solution offers a powerful automated consolidation of both items arriving directly at the user’s workstation, thus eliminating the need for warehouse operators to move around the warehouse floor for picking and additional packing.

There’s been a long-standing need for a solution in Australia that enables automated picking of both bulky and smaller items.

Up until now, warehouses have had to apply very archaic methods of processing orders that combine bulky and smaller items. While varying degrees of refinement of the process have been developed, HAI’s fully automated and speedy solution combining ACRs and AMRs to pick from multiple locations and consolidate the order items at a single workstation has entirely revolutionised this process.

This flexible solution has been successfully launched in EMEA, ANZ, SEA, South Korea, and China and is providing customers with a seamless and efficient automated workflow and a productivity increase of more than 60% – in addition to the benefits of high-density storage.