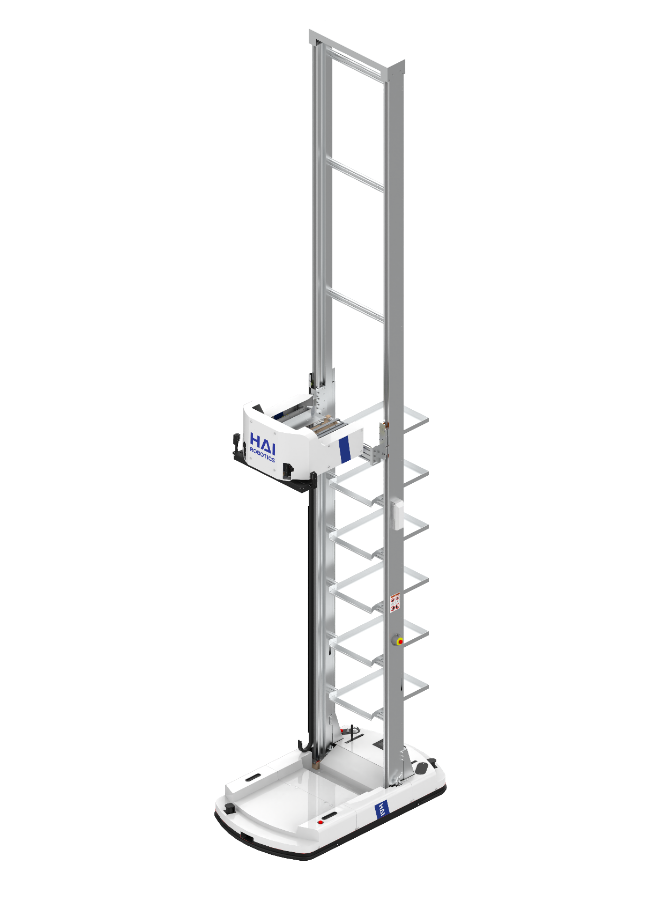

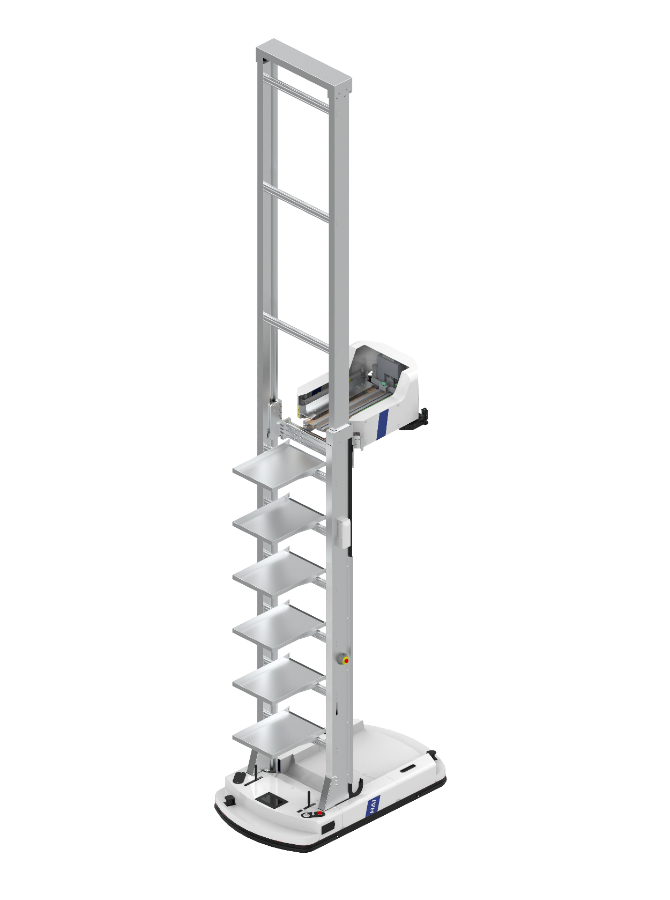

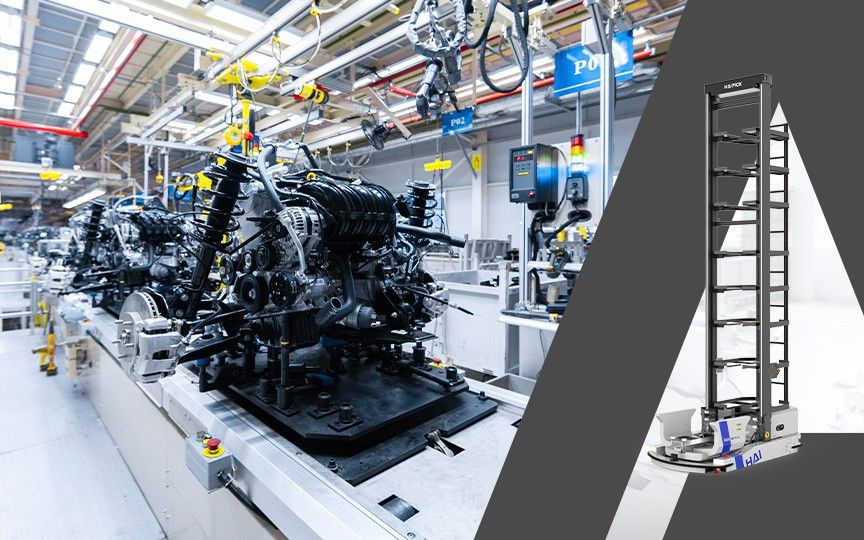

Grappling-hook ACR

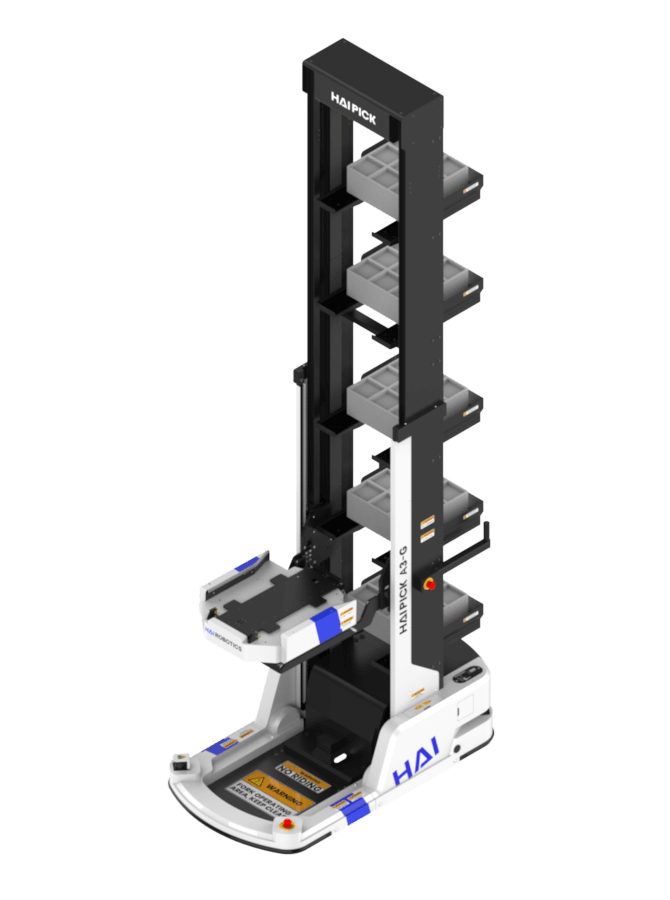

HaiPick A42-E6S

HaiPick A42-E6S Grappling Hook Automated Case-handling Mobile Robot (ACR), has been specially designed to handle totes stored on single- up to triple-deep racks, and its maximum payload can reach up to 300 kg. With this state-of-the-art product, you can experience enhanced storage density and area efficiency.

Ultimate space reduction

• Horizontal case space reduced down to 30mm

• Longitudinal case space reduced down to 0mm

Multiple deep options

• Up to three-deep tote storage, improve storage density by 150%

Highly automated warehousing

• Shorter turnaround time, increases handling efficiency by 30%

Quick disassembly

• Saves 10% of transportation and maintenance costs

Enhanced Safety Features

• Experience superior case-handling stability features and LiDAR collision avoidance. Our multiple security measures ensure robust reliability and top-of-the-line facility safety.

HaiPick A42-E6S Grappling Hook Automated Case-handling Mobile Robot (ACR), has been specially designed to handle totes stored on single- up to triple-deep racks, and its maximum payload can reach up to 300 kg. With this state-of-the-art product, you can experience enhanced storage density and area efficiency.

Ultimate space reduction

• Horizontal case space reduced down to 30mm

• Longitudinal case space reduced down to 0mm

Multiple deep options

• Up to three-deep tote storage, improve storage density by 150%

Highly automated warehousing

• Shorter turnaround time, increases handling efficiency by 30%

Quick disassembly

• Saves 10% of transportation and maintenance costs

Enhanced Safety Features

• Experience superior case-handling stability features and LiDAR collision avoidance. Our multiple security measures ensure robust reliability and top-of-the-line facility safety.

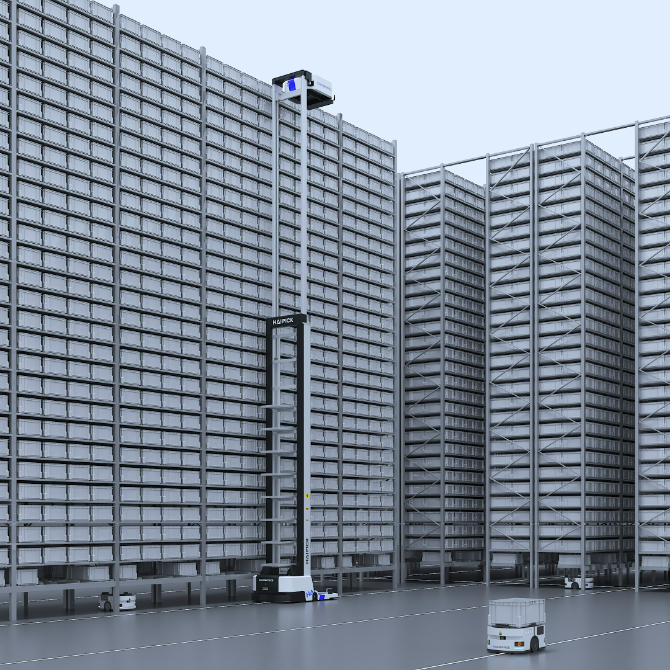

Product Features

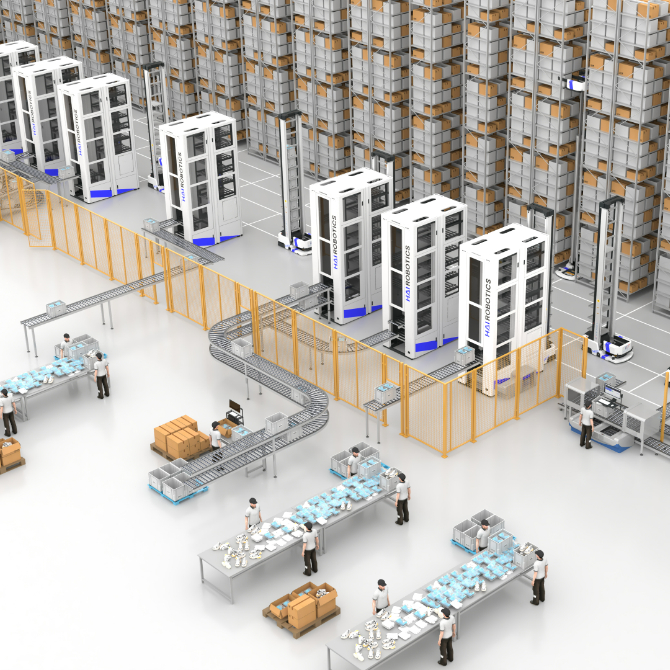

Discover the power of our ACR solutions – your key to conquering the challenges of modern grocery fulfillment.

Increase storage density by 80-400% and space utilization rate.

Easy to expand, transform, and relocate, quick response to market demands, and business changes.

Increase operational efficiency by 3-4 times per worker, working accuracy 99.99%.

Support 2B, 2C, bonded warehouse, and other businesses to meet diverse needs.

Flexibly respond to customized production requirements and facilitate efficient manufacturing.

Optimize operation procedures, improve storage efficiency, and shorten investment return cycles.

Reduce operating costs and meet diverse production and industry scenarios.

Downloads