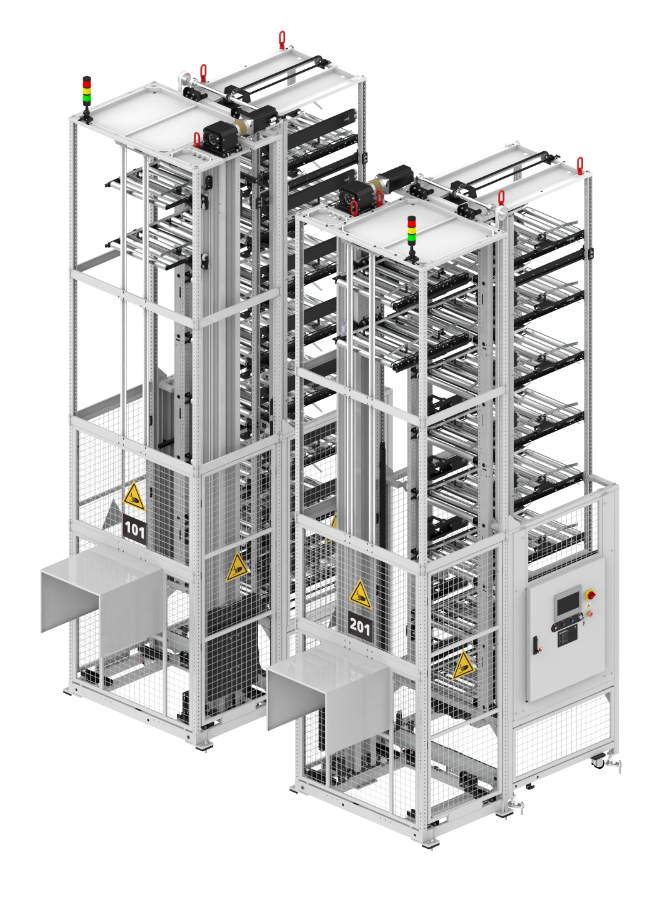

Fork-Lifting ACR

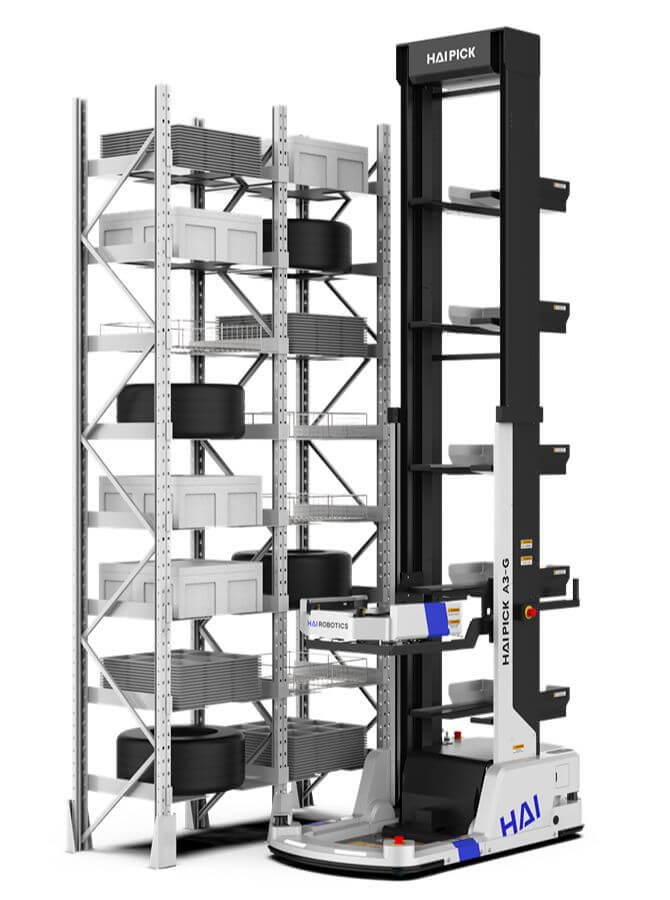

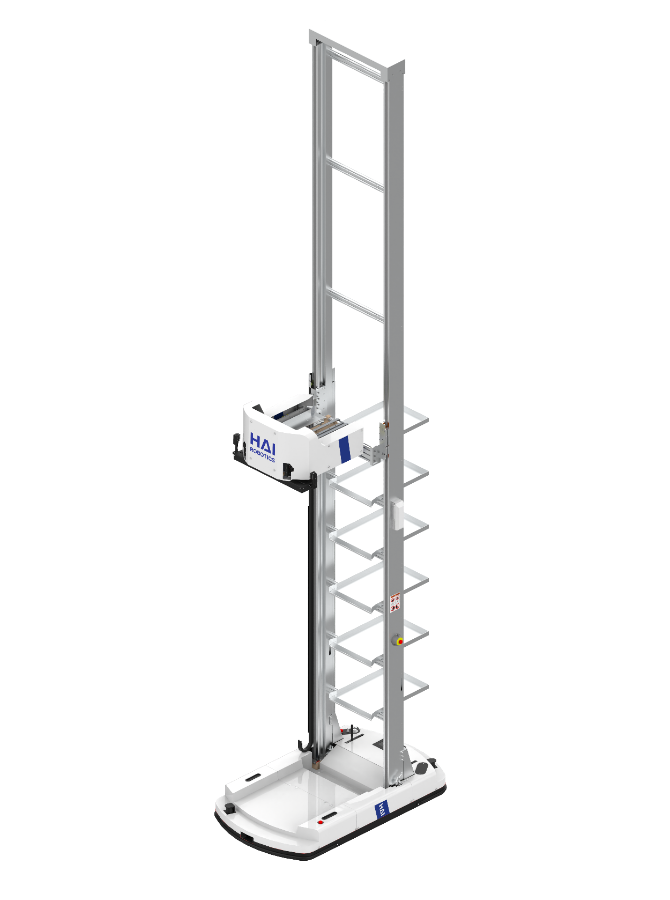

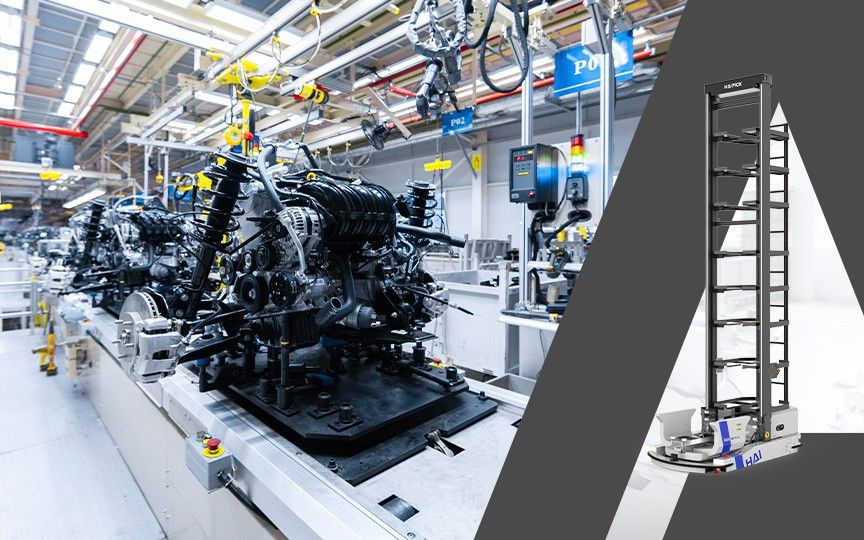

HaiPick A3

With up to 5.5m(18 feet) picking height, the A3 series provides high utilization of storage space. Adaptable to manufacturing operations, the series can store, pick and move goods of different shapes such as tires, trays and foam boxes. Our autonomous warehouse robots are also suitable for dust-free requirements, handling goods such as PCBs.

Picks a Wide Variety of Materials:

Trays, tires, foam boxes, and many others, meet the needs of manufacturing industries, such as electronics, automotive, etc.

Class10000 Cleanliness and Anti-static:

The load handling device is dustproof and anti-static, suitable for handling goods such as PCBs.

Customizable:

A large range of standard customizations is available. The A3-series can work with different types of shelves, conveyors and other docking equipment.

Integration Flexibility:

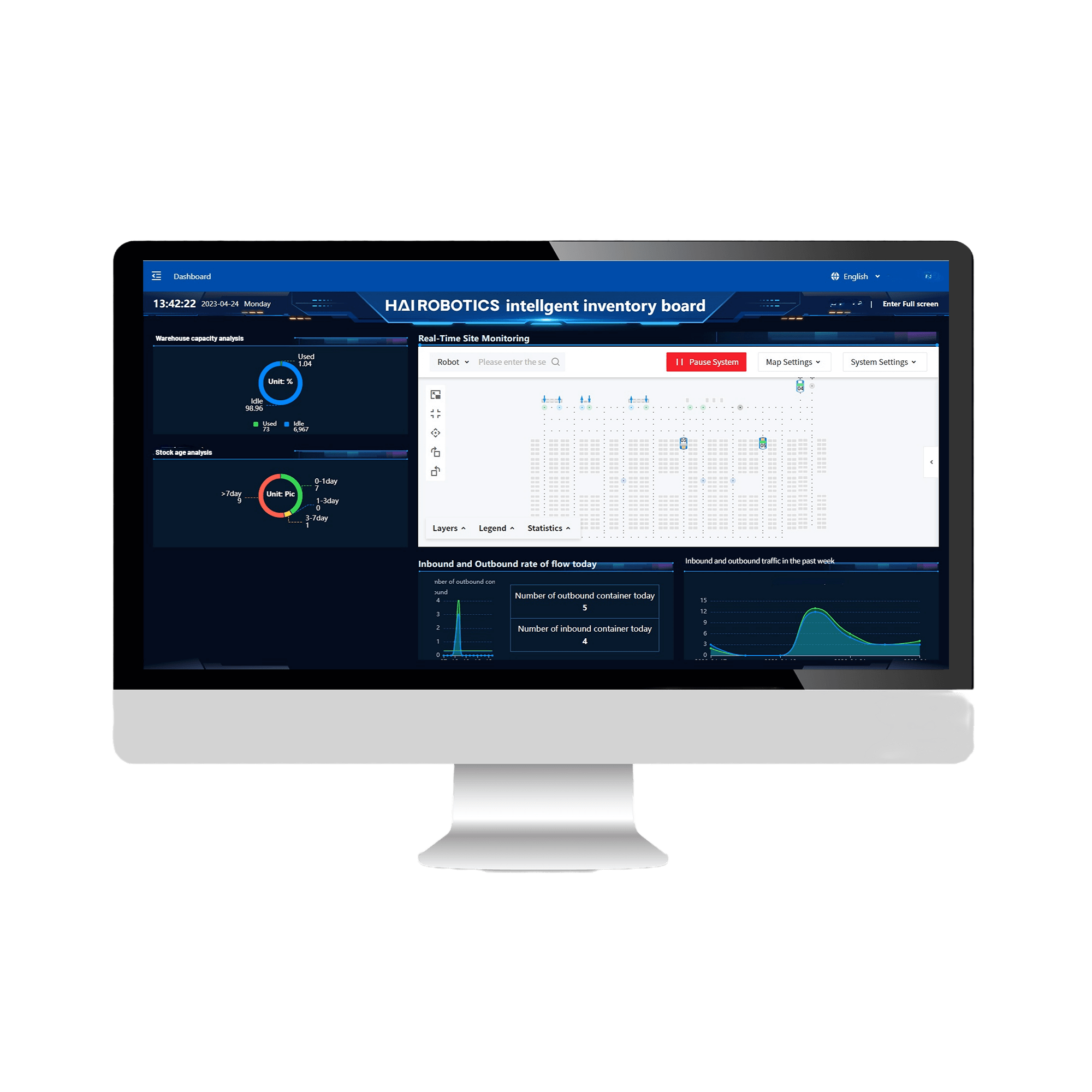

As with any HaiPick-series, the software platform can integrate with almost any upstream software platform for the purpose of orchestrating and automating processes within warehousing and manufacturing.

Product Safety:

CE+NRTL certified.

* The HaiPick A3 models are not available in Japan. Please contact us for more information.

With up to 5.5m(18 feet) picking height, the A3 series provides high utilization of storage space. Adaptable to manufacturing operations, the series can store, pick and move goods of different shapes such as tires, trays and foam boxes. Our autonomous warehouse robots are also suitable for dust-free requirements, handling goods such as PCBs.

Picks a Wide Variety of Materials:

Trays, tires, foam boxes, and many others, meet the needs of manufacturing industries, such as electronics, automotive, etc.

Class10000 Cleanliness and Anti-static:

The load handling device is dustproof and anti-static, suitable for handling goods such as PCBs.

Customizable:

A large range of standard customizations is available. The A3-series can work with different types of shelves, conveyors and other docking equipment.

Integration Flexibility:

As with any HaiPick-series, the software platform can integrate with almost any upstream software platform for the purpose of orchestrating and automating processes within warehousing and manufacturing.

Product Safety:

CE+NRTL certified.

* The HaiPick A3 models are not available in Japan. Please contact us for more information.

Product Features

Reduce operating costs and meet diverse production and industry scenarios.

Flexibly respond to customized production requirements and facilitate efficient manufacturing.

Optimize operation procedures, improve storage efficiency, and shorten investment return cycles.

Downloads

Download our latest industry report and learn how ACR powers different sectors. You'll learn exactly what ACR is and why it's different and so powerful.

Download the white paper and discover what industry leaders think about the future of warehouse automation, the impact it would have on workforces and sustainability, the risks facing the industry, and the potential avenues for collaboration to drive forward progress.

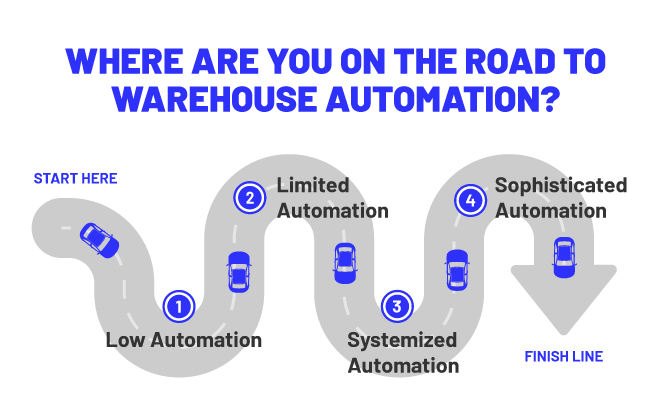

If you are exploring ASRS solutions for your facility, know these 6 critical tips to help you identify the best solution for you. Discover tips to identify inefficiencies in your facility workflows and what to look for when exploring automated storage that can help you achieve the largest return.