Baoshi Logistics

Apparel Warehouse Project

11,200

Storage Locations

1,435 cases

Warehouse Efficiency Per Day

99.9%

Picking Accuracy

Fast

Return on Investment

--Manual picking is inefficient and error-prone

--Low storage space and low density

--Information management is difficult

Our Solution

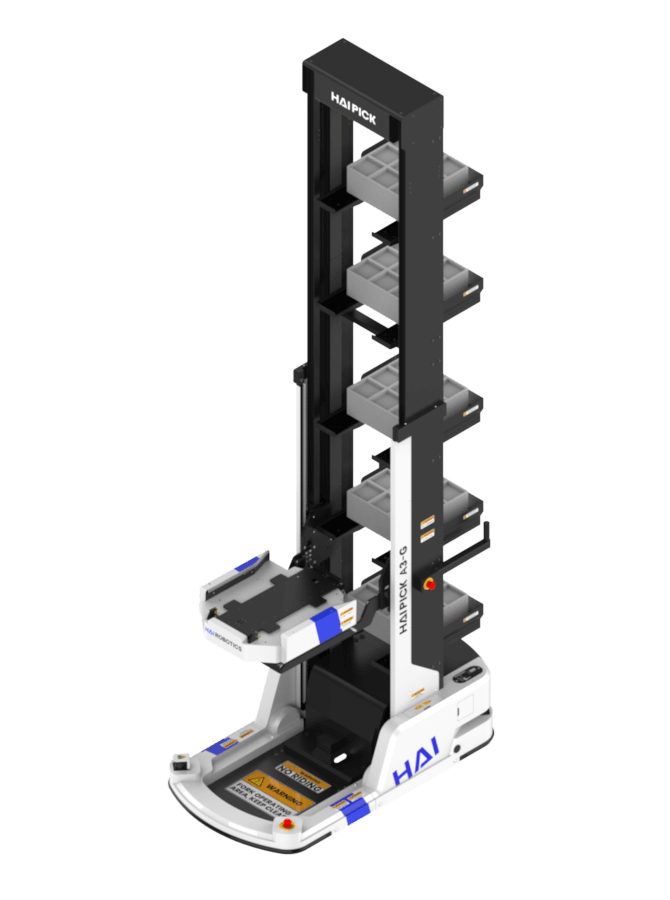

--Robot quantity & type: 5 units, A42

--Charging stations:2

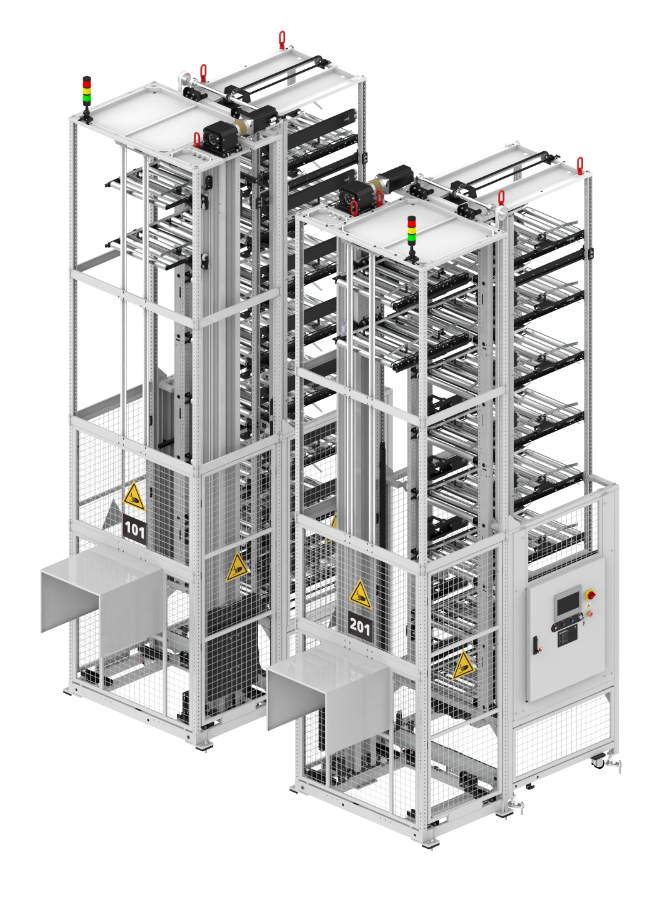

--Workstation type & quantity: 1 on-shelving workstation + on-conveyor workstation

--Shelving height: 4,100mm

--Storage unit type/size: Tote 600mm(L)×400mm (W)×300mm (H)

--Warehouse area: 500㎡, achieving 11,200 storage locations

--The robot automatically docks the conveyor line to take and unload the totes to improve the efficiency of the robot's work. The robot can carry 8 totes at a time

--Reducing manual walking and operating fatigue

--10 hours of operation per day, meeting the maximum total case handling efficiency of 1,435 cases/day (inbound + total outbound flow)