ERAL

Apparel Factory

1,008

Storage Locations

50 cases

Peak Inbound/Outbound Efficiency Per Hour

26 cases

Storage Density Per Square Meter

7 days

Complete Deployment

--Customized items, increasing demand for multi-variety. Production in small batches.

--Warehouse demand is scattered. The processing completion time of each line type piece is different.

--Complex kitting process with thousands of items.

--The low-density storage area is designed for manual picking.

Our Solution

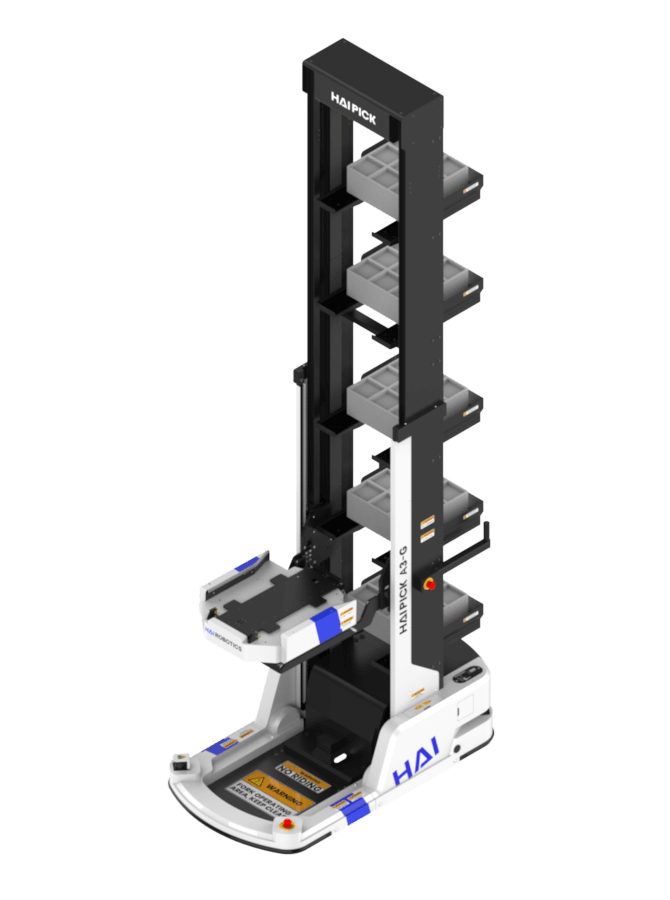

--Robot quantity & type: 2 units, A42

--Charging stations:2

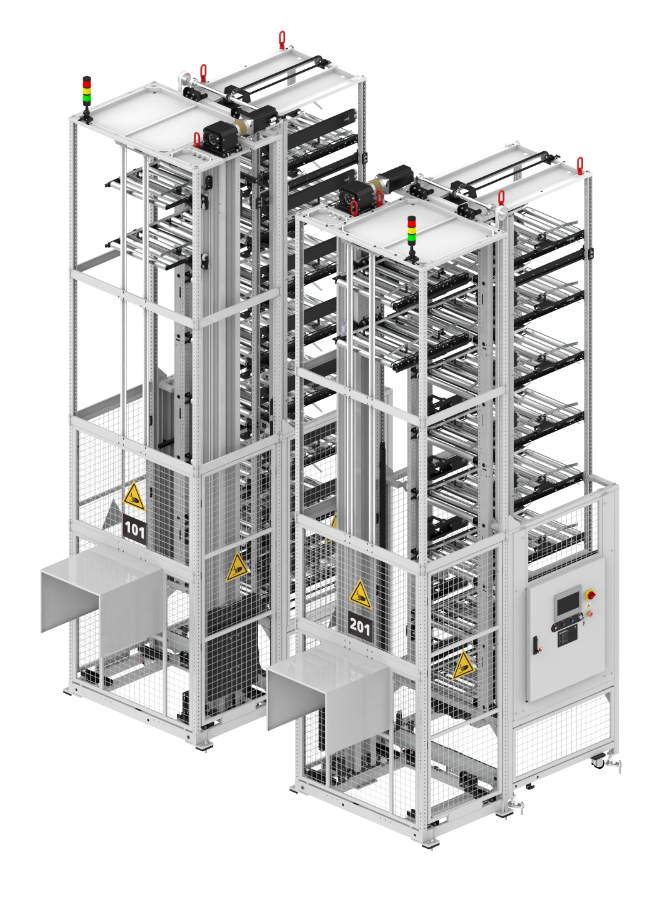

--Workstation type & quantity: 2 inbound workstations + 1 outbound workstation

--Shelving height: 4000mm

--Case type/size: tote 650mm(L)×440mm(W)×400mm(H)

By implementing Hai Robotics' advanced technologies, ERAL witnessed a remarkable improvement in its production and kitting processes. Automation streamlined these operations, reducing lead times and enabling the company to meet the growing demands of its customers more effectively.

Moreover, Hai Robotics' intelligent system revolutionized data management for ERAL. This not only saved valuable time but also enhanced the accuracy and reliability of data, allowing ERAL to make informed decisions swiftly.

Perhaps the most significant impact of Hai Robotics' solution was the optimization of storage density. Through their state-of-the-art technology, ERAL was able to maximize every inch of its warehouse, significantly reducing the storage area required. This not only saved costs but also allowed for the seamless expansion of inventory without compromising operational efficiency.

--Warehouse area: 47㎡, storage area: 38㎡, achieving 1,008 storage locations and 26 cases/sqm storage density.

--Each robot can carry up to 8 cases, significantly improving efficiency.

--HaiPick robots dock directly with workstations for inbound and outbound processes reducing manual operation.

--Inbound/outbound efficiency achieves 35 cases/hour, with a peak of 50 cases/hour.

--The HaiPick robots realizes outbound processes based on complete set of materials, significantly improving efficiency and accuracy.

--Automated picking and kitting processes.

--1 week for deployment, 1 month to go live.