A Global Premium Brand in Consumer Electronics

New Automation Deployment

40,000

Storage locations

1,170

Outbound totes per hour

4,000+

SKU

Fast-Scaling Operation:

The fulfilment center needed to accommodate aggressive SKU and volume growth from a global brand.

High Storage Density:

Efficient use of vertical space was critical to meet long-term capacity requirements within the 41m x 70m warehouse footprint.

Throughput Pressure:

High daily order volumes demanded a system capable of handling thousands of totes per day.

Manual Inefficiencies:

Prior to automation, fulfilment was constrained by low outbound speed and labor-intensive operations.

Our Solution

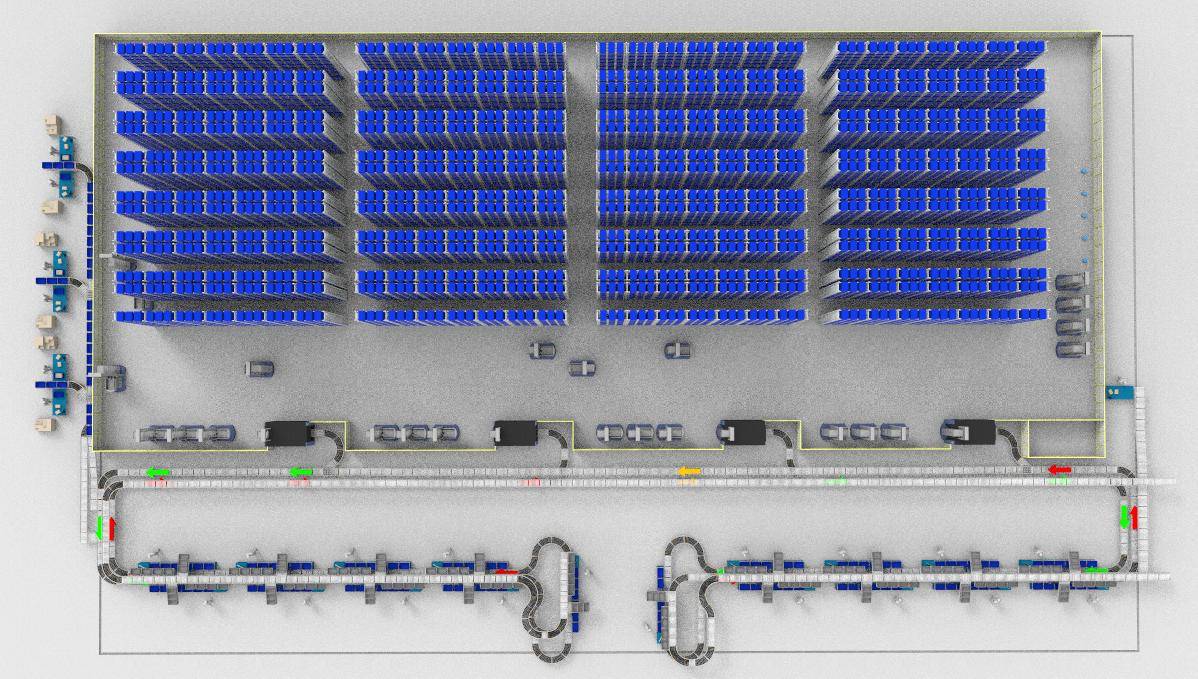

To address these challenges, Hai Robotics deployed a modular automation layer based on its flagship autonomous case-handling robot (ACR) system. The solution was delivered in close collaboration with Inteq - the appointed system integrator for the project.

-

43 HaiPick A42T robots, enabling vertical picking up to 10 meters

-

15 charging stations to sustain continuous operation

-

3 pairs of HaiPort, supporting high-speed tote handover

-

ESS-to-HaiPick system integration, enabling real-time coordination across all robot movements

The automation zone spans the entire 41m x 70m footprint with 10 meters of clear height, maximizing cubic utilization. A dedicated picking zone includes 16 workstations operating in conjunction with the HaiPort interfaces, forming the core of a highly efficient goods-to-person workflow. System architecture enables up to 1,170 tote transfers per hour, evenly distributed across the three HaiPort pairs.

Hai Robotics was also responsible for the robot layer and its scheduling system (ESS), which integrates seamlessly with the broader warehouse automation infrastructure delivered by Inteq.

Why Hai Robotics

As part of the project partnership, Inteq worked with Hai Robotics to integrate a best-in-class ACR system. Hai Robotics was selected for its depth of expertise in high-density, high-throughput fulfilment, and for its flexible, modular approach to integration.

- Dedicated technology focus: While other vendors proposed hybrid solutions combining AMR and ACR, Hai Robotics provided a fit-for-purpose ACR solution tailored to high-density fulfilment.

- Scalable architecture: The modular system enables the client to scale capacity incrementally in alignment with business growth.

- Customer-first mindset: Hai Robotics worked closely with both the 3PL and Inteq to co-develop a tailored solution, emphasizing long-term value over short-term standardization.

Results & Impact

Although the project is still ramping up after a soft launch in late 2023, the fulfilment center is already achieving strong early performance indicators:

-

Storage Efficiency: Estimated capacity of ~40,000 storage locations in a compact footprint

-

High Throughput: System architecture supports up to 1,170 outbound totes/day across e-commerce and retail channels

-

Future-Ready Design: Built to support five years of projected growth without significant structural modification

By combining Hai Robotics’ advanced ACR capabilities with Inteq’s full-stack automation integration, the client has created a high-performance fulfilment operation that balances density, speed, and scalability - ready to meet the evolving demands of the UK market and beyond.