Top Internet Company

Complementary Product Warehouse

5,668

Storage Locations

2 times

Increase Storage Height

99.9%

Picking Accuracy

--Most of the items are small, including zippers, buttons and clothing labels. There is no bar code and it is difficult to manage

--The complete set of outbound picking is very difficult. The required assembly items need to be found from thousands of materials, manual picking efficiency is very low

--There are many kinds of SKUs, the storage density in the manual warehouse is low and effective picking area is small

--The warehouse is manually managed, lack of WMS system to manage information

Our Solution

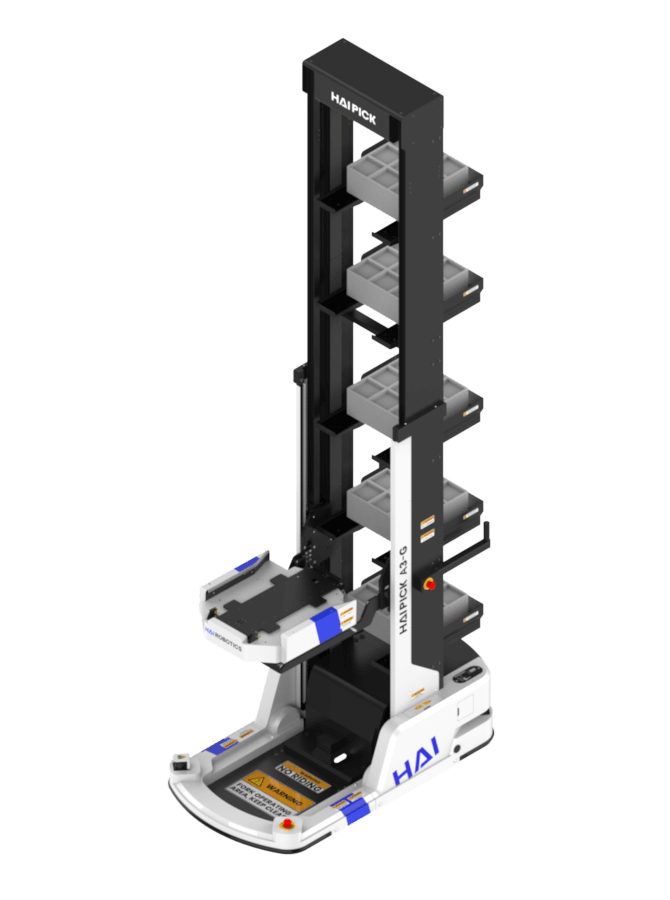

--Robot quantity & type: 11 units, A42

--Charging stations:4

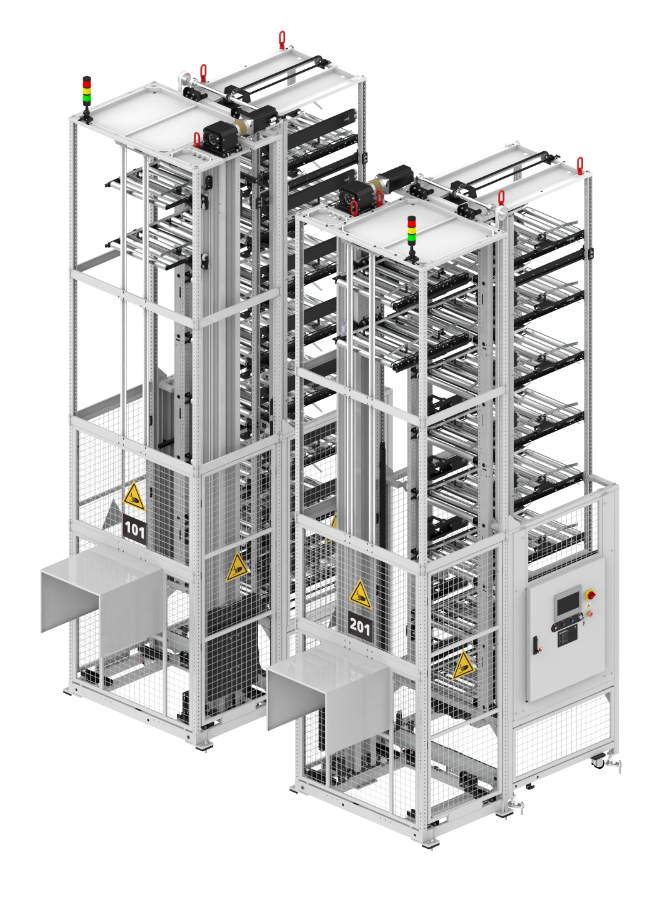

--Workstation type & quantity: 5 (3 on-shelving picking workstations + 2 on-conveyor picking workstations)

--Shelving height: 4,100mm

--Case type/size: tote 600mm(L)×400mm(W)×300mm(H)

--Warehouse area: 570m²; Provided 5,668 storage locations

--Codes are manually pasted, and the code information is sent to HAIPICK System through WMS, this way the goods can be identified and managed.

--HAIPICK ACR robots realize case-to-people handling, and the put-to-light system realizes semi-automatic distribution, which greatly improves the picking efficiency

--The maximum storage height is 4,000mm, which is twice the manual storage height, increasing the effective picking area

--HAIPICK system directly connects to customer’s WMS system with API to realize full information management.