Qiaodan

Apparel Logistics Center

31,230

Storage Locations with 4,300㎡

3 times

Increase Mixed Case Picking Efficiency

600 pieces

Return Putaway Efficiency Per Hour Per Person

99.9%

Picking Accuracy

--Low labor efficiency, manual picking realizes 100-120 pieces/hour/person

--Manual warehouse storage density is low, and the effective picking area is small

--Too many return processing steps and the putaway efficiency is low, overall only 50 pieces/hour/person

--Use manual paper picking, difficult to guarantee the accuracy and timeliness of information and data

--The number of SKUs in the return warehouse is low, but with a large variety, which makes it difficult for manual picking

Our Solution

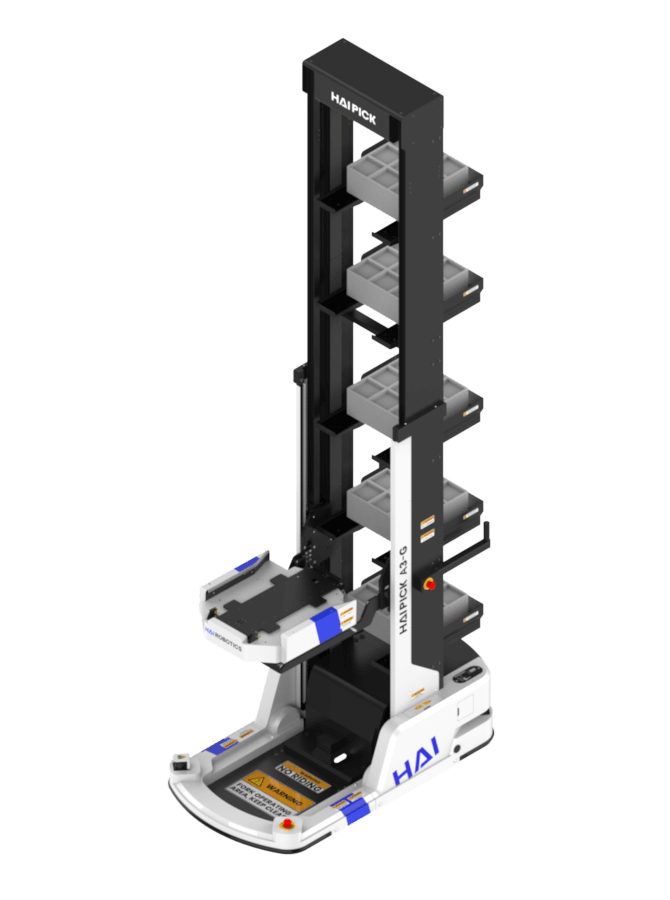

--Robot quantity & type: 26 units, A42L

--Charging stations:9

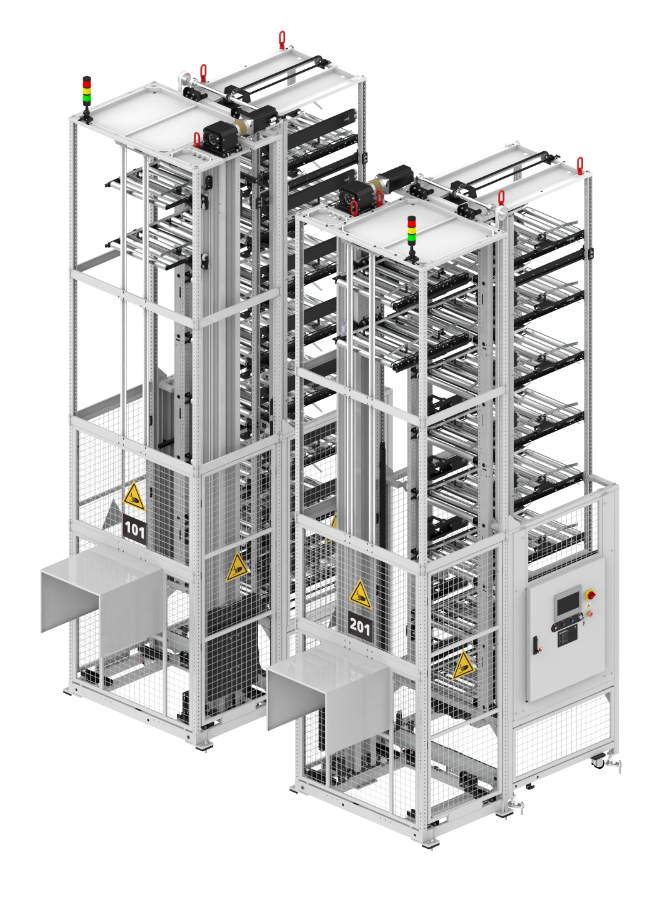

--Workstation type & quantity: Outbound: 1 conveyor ring 3 workstations + 4 HAIPORT

--Inbound: 1 conveyor ring 3 workstations

--Shelving height: 5,300mm

--Storage unit: totes 650mm(L)×440mm(W)×400mm(H)

--Shelving area of 4,300㎡ provided 31,230 storage locations

--Case-to-person method, B2C picking efficiency achieves 420 pieces/hour/person

--5.3m high shelves increase storage density by 0.5 times

--Autonomous putaway of returns + case-to-person picking, achieves a return putaway efficiency of 600 pieces/hour/person

--Through grid storage + visual picking, the efficiency of mixed case picking increased more than 3 times

--Outbound efficiency 400 pieces/hour/person, inbound efficiency 600 cases/hour/person, reducing inbound/outbound time

--Inventory information and pick information in real time significantly improves the reliability of information system