SAIC GM Wuling (SGMW)

Assembly Shop KLT Warehouse

10,752

Storage Locations within a 1,100m² Warehouse

660 cases/h

Increased Inbound & Outbound Efficiency

5.5 meters

Utilized Full Vertical Storage Space

99.99%

Picking Accuracy

SGMW realized with the expansion of its business that it needed to upgrade its traditional manual ‘person to goods’ warehouse. To help meet high-pressure performance metrics and rising consumer demand, Anji CEVA and SGMW needed to solve the following pain points:

--Scattered Kanban orders and lengthy, cumbersome personnel processes led to stocking, shelving and picking issues

--Insufficient operational efficiency due to business expansion

--Low facility space utilization led to inadequate material storage space

--Uncertainty in assembly line demands and sizable fluctuations in business volume contributed to low operational efficiencies with the manual production lines

Our Solution

The bespoke solution SGWM implemented consisted of the following:

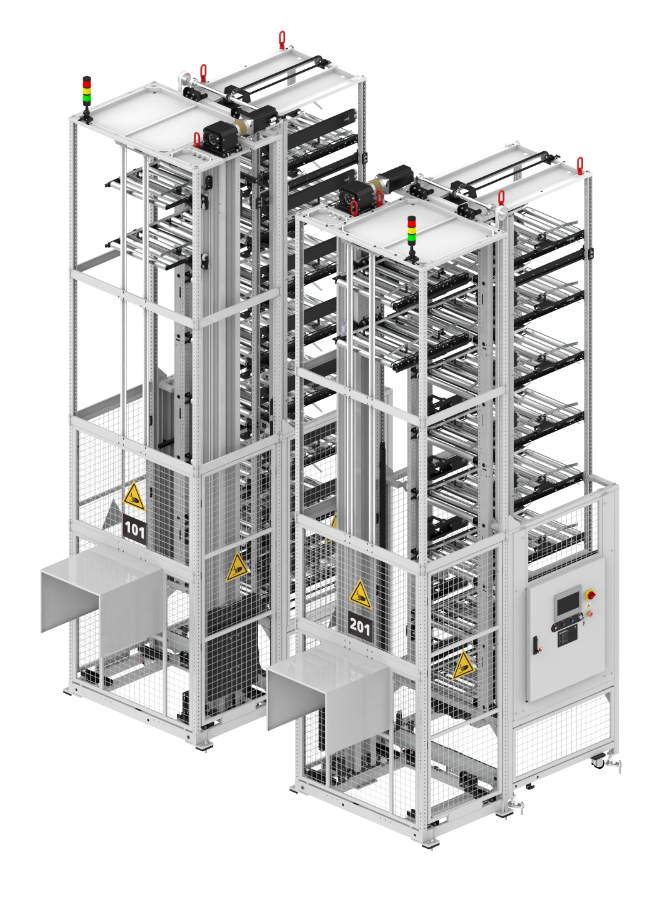

--15 Compact Twin Fork ACRs

To empower efficient goods-to-person inbound and outbound picking and placing

--Racking picking height: 5.5m

To take full advantage of the facility’s maximum storage height

--3 sets of Outbound and 1 set of Inbound HaiStations

To facilitate 99% accurate picking and streamlined operations

--Multi-size tote and cartons:

to accommodate various part sizes:

800mm(L)*600 mm(W)*280 mm(H)

600mm(L)*400mm(W)*280mm(H)

400mm(L)*300 mm(W)*280 mm(H)

300mm(L)*200 mm(W)*280 mm(H)

Anji | CEVA SGMW were able to overcome its facility’s challenges and accomplish milestones to propel expansion and improve their bottom line.

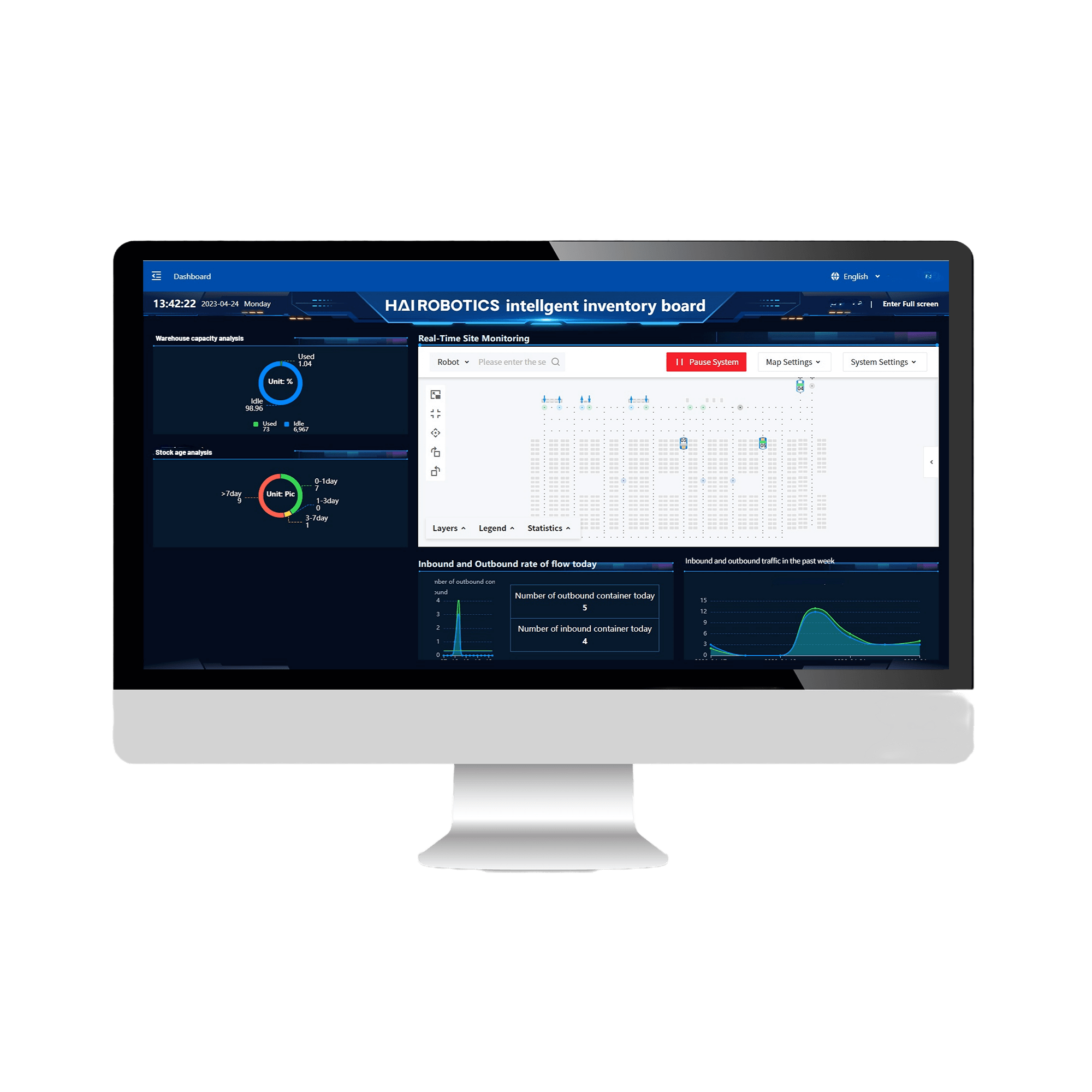

--Maximized storage utilization by achieving 10,752 storage locations in a storage area of 1100㎡

--Increased inbound & outbound efficiency to reach 660 cases/h

--Utilized full vertical storage space to implement shelves as high as 5.5 meters

--Accelerated the precise and timely scheduled management of parts

--Improved parts delivery accuracy to empower SAIC-GM-Wuling’s production goal of 70 cars per hour

The current intelligent system solution, whether regarding efficiency or storage density metrics, is a substantial improvement in production requirements.

The current intelligent system solution, whether regarding efficiency or storage density metrics, is a substantial improvement in production requirements.