Umall

Sydney Dry Goods Warehouse

11,000

Storage Locations in a 1,000㎡ Area

8,000 pieces/d

Daily Delivery Efficiency

400 boxes/h

Inbound Efficiency

99.99%

Picking Accuracy

Operating in a high-velocity e-commerce environment, Umall faced several challenges within its Sydney warehouse:

- Labor-intensive picking processes increased operating costs and made workforce stability difficult to maintain.

- Manual operations limited picking efficiency and consistency, impacting fulfillment speed and accuracy.

- Storage capacity was constrained by the existing warehouse layout, restricting scalability within the same footprint.

- Managing a wide SKU range across different product categories added complexity to inventory control and daily operations.

These challenges made it clear that a more automated, scalable warehouse model was required.

Our Solution

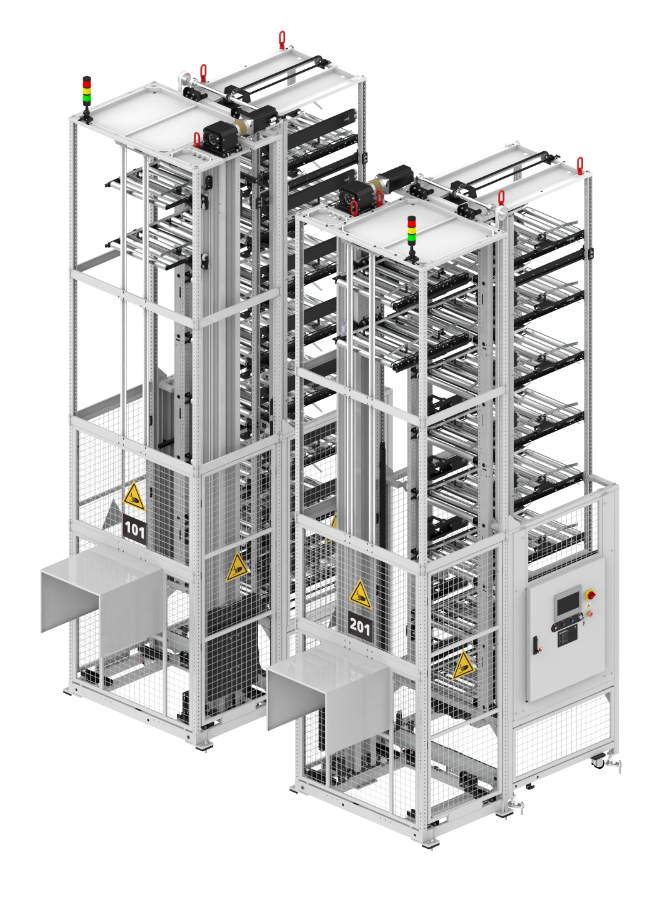

Umall partnered with Hai Robotics to deploy a HaiPick System 1 to transform its warehouse into a highly efficient, goods-to-person operation.

The solution combines autonomous case-handling robots, high-density racking, and optimized workstations to streamline inbound, storage, and outbound processes—while remaining flexible enough to adapt as business needs evolve.

Key features of the deployment:

- Warehouse Area: 1,000 square meters

- Shelving Height: 7.9 meters

- Robots: 13 HaiPick A42 robots, 7 HaiPick A42T robots

- Workstations: 3 inbound workstations, 10 outbound workstations

- Storage Capacity: Accommodating 11,000+ locations

- Outbound Efficiency: 8,000 pieces per day

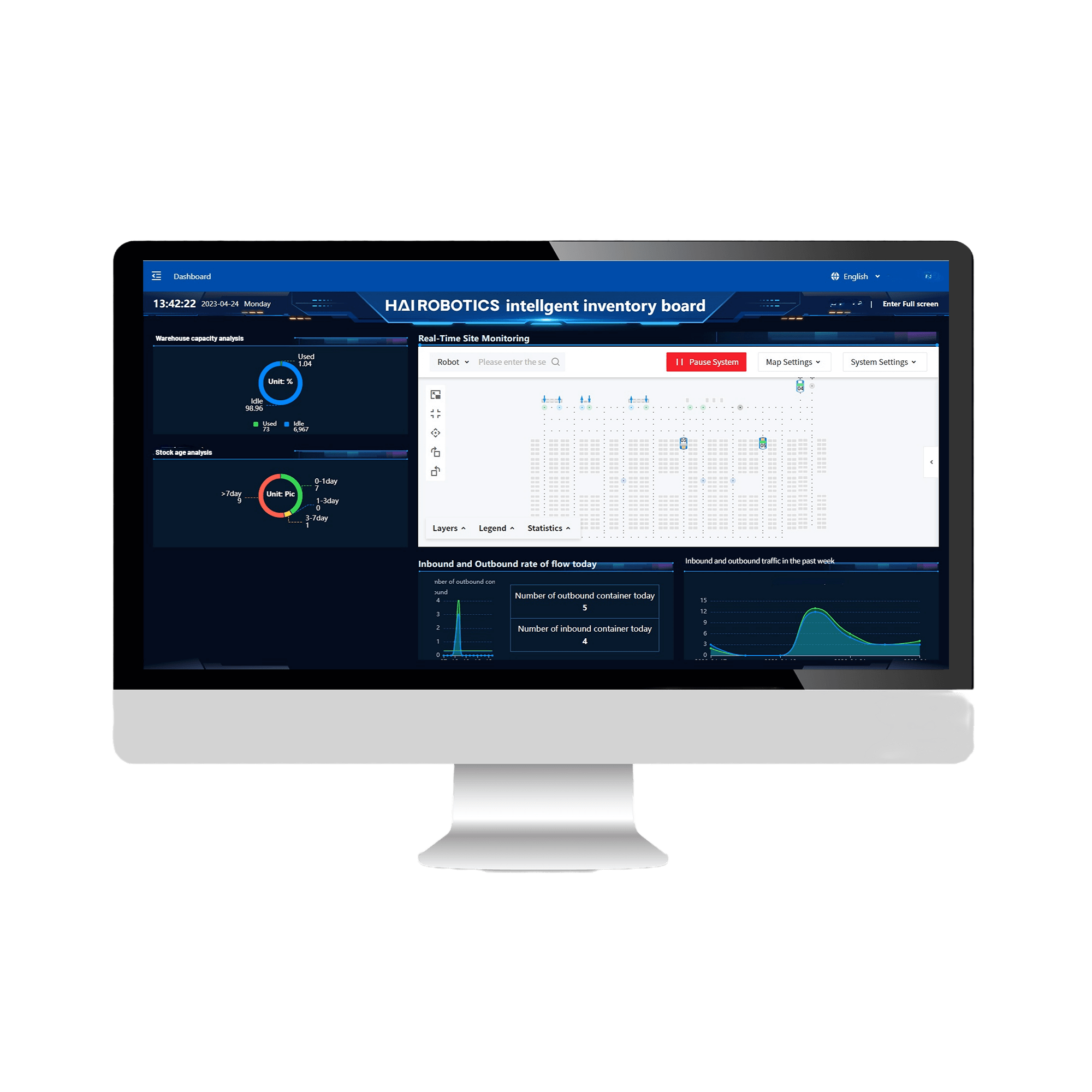

The HaiPick solution delivered immediate and measurable value to Umall’s warehouse operations:

- Higher storage density Vertical storage significantly increased capacity within the existing warehouse footprint.

- Improved picking efficiency Goods-to-person workflows reduced travel time and accelerated order fulfillment.

- Lower labor dependency Automation minimized manual handling, helping stabilize operations and control labor costs.

- Greater accuracy and inventory visibility Systematic automation reduced errors and improved inventory control.

- Better customer experience Faster, more reliable fulfillment supported shorter delivery times and higher customer satisfaction.

- Scalable operations for future growth The flexible HaiPick system enables Umall to expand throughput and capacity as demand continues to rise.