BPS Global Australia Selects Hai Robotics to Power Future Growth Plans for Harvey Norman Commercial Division

BPS Global Australia has selected automation solutions from Hai Robotics to expand Harvey Norman Commercial’s SKU capacity, improve lead times and target future growth at its Sydney facility.

BPS Global Australia has selected automation solutions from Hai Robotics to expand Harvey Norman Commercial’s SKU capacity, improve lead times and target future growth at its Sydney facility.

Harvey Norman Commercial Division provides an extensive selection of brand-name products to builders, developers, architects, and designers.

Committed to innovation and improving its service offering, the leading retailer has invested heavily in automation technology that is set to transform its operation at its facility in Sydney’s southwest.

The retailer’s new purpose-built facility features a range of automation technology, including materials handling robots from tech pioneer, Hai Robotics known for their next-genration robotic warehouse solutions that have been implemented in various industries, including fashion, 3PL, retail, electronics, healthcare, and e-commerce.

Located at Crossroads Logistics Centre, the Harvey Normal Commercial Division’s 18,000 sqm site stores more than 60,000 stock keeping units (SKUs), an impressive jump from its previous facility in Taren Point – which held 20,000 SKUs across 12,000 sqm.

“We’ve experienced rapid growth across our service offerings in the past couple of years and have made the decision to invest significantly in our supply chain capabilities,” said Kabe Franklin, Merchandise Manager at Harvey Norman Commercial Division.

Harvey Norman Commercial Division selected BPS Global Australia to advise, design and implement the full system. BPS selected Hai Robotics as it’s a key component of the automation solutions.

According to Paul Philips, General Manager at Hai Robotics ANZ, as the retailer deals with a lot of small electrical and general merchandise products, the Hai solutions were a perfect fit for Harvey Norman Commercial Division.

“Our multi-layer autonomous case-handling robot features a next-level autonomous navigation method that does not rely on a rail system, enabling to travel freely around the workspace. Harvey Norman selected 10 of our ACR robots which deliver efficient handling as well as provide high density and high throughput,” Paul says.

The HaiPick robots and paired HaiPort tote dispensers, deliver multiple totes to workstations for seamless picking.

“The system eliminates all walking within the aisles of the fulfilment centre. The products are presented in totes in an efficient manner to the user at the workstation after which the product is picked into the order tote and sent off for subsequent workflows of packing and transportation,” Paul says.

Designed and installed by BPS Global Australia, Harvey Norman Commercial Division has invested in an array of state-of-the-art technology – including goods to person pick stations, a CMC automated packaging machine, satchel pack machines, very narrow aisle stock pickers by Toyota Material Handing and a Warehouse Management System (WMS) by Thomax Technology.

“Harvey Norman Commercial Division is focused on future growth and needed new technology to achieve its ambitious targets. We have worked with the leading retailer to find and design the most suitable automation technology for its new facility – and the Hai solution is a central part of this,” Malcolm Druce, Managing Partner at BPS Global Australia says.

BPS reviewed Harvey Norman’s existing operation and the new site was then designed so that the retailer could flex up as its sales and customer base grow.

“We have worked with Harvey Norman to ensure that the build is fit for purpose, we’ve reviewed the forklift operations to design better processes and we’ve designed the entire system layout. The Hai Robotics solution serves as the lynchpin to the entire operation,” Malcolm says.

The Hai Robotics solution allows Harvey Norman Commercial Division to scale up and down as demand fluctuates and also enables same-day picking – with waves of orders being picked and packed in less than 90 minutes.

Whilst the new solution is in its infancy, the go-live and project launch went extremely well.

“We’ve successfully transferred to a new site with all of the new technology and we haven’t had any downtime. We’ve been operating a progressive go-live with staggered testing and UAT so as to reduce the risk on the business,” Malcolm Druce says.

According to Hai’s Paul Philips, a further benefit of the solution is the user experience. “The interface presented to the user is very simple to understand and has removed the need for extensive training. Users can enjoy a safe environment with minimal handling and there is now no walking required to pick products and fulfil orders,” he says.

Kabe Franklin, Merchandise Manager at Harvey Norman Commercial Division says by partnering with BPS Global Australia and Hai Robotics, he’s confident the retailer has deployed the right automation. “This tech suite is exactly what we need to grow, and we look forward to delivering the very best experience and service for our customers,” he says.

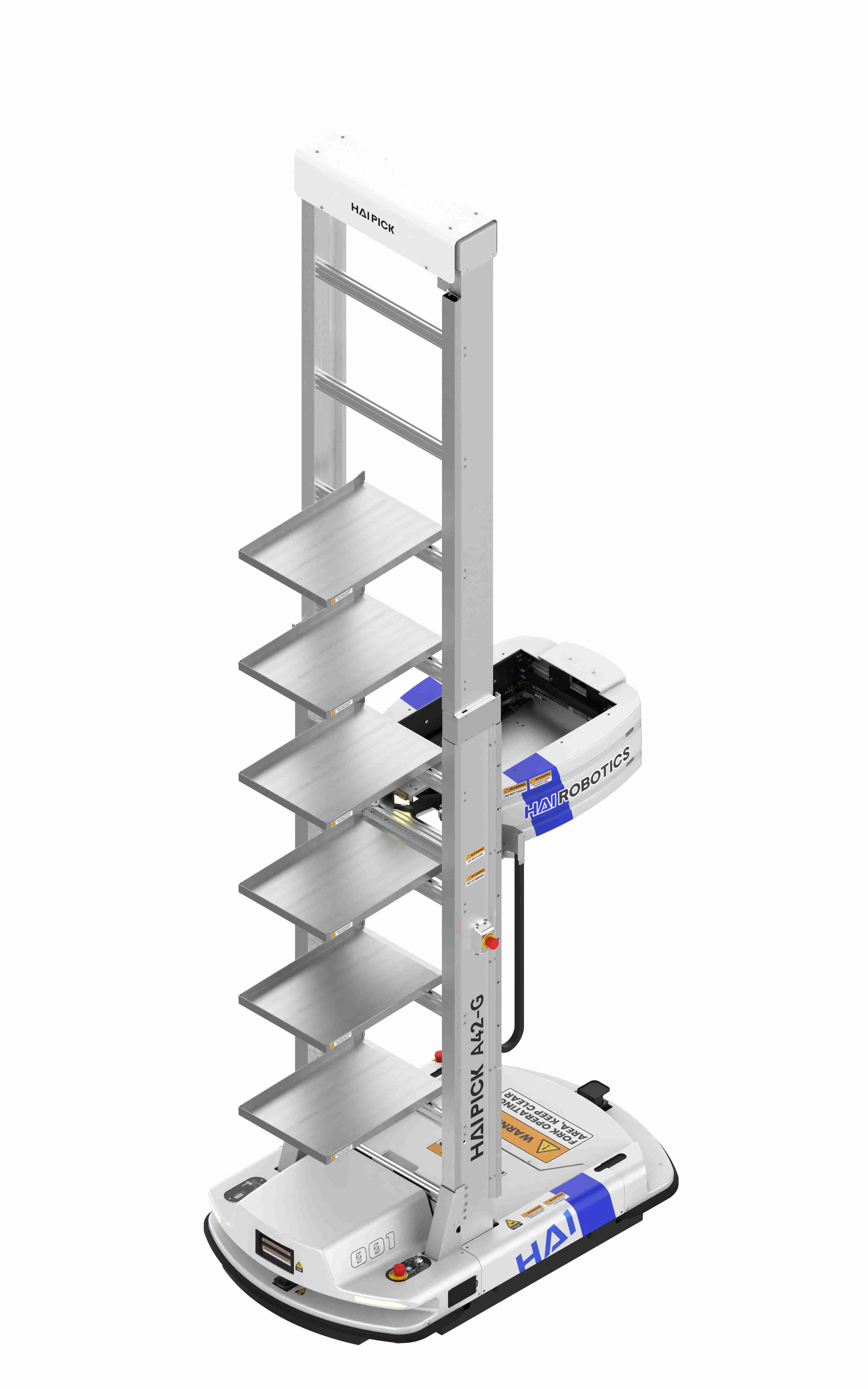

HaiPick A42-G

HaiPick A42-G-E4, the multi-layer autonomous case-handling robot (ACR), helps handle cases intelligently with the maximum payload of up to 300 kg. It features a next- level autonomous navigation method that does not rely on a rail system, enabling it to travel freely around the workspace. Additionally, the robot can detect obstacles and plan for charging automatically, ensuring uninterrupted operation.

Features

• Accurate positioning and navigation: using the IMU and DM code navigation method

• Efficient handling: capable of processing up to 8 totes simultaneously as equipped with multiple storage trays

• High compatibility: providing an adjustable-width fork option for complex picking scenarios that contain both totes and cartons

• Smooth traveling: adopting a differential-wheeled design that ensures smooth traveling and rotating

• Easy usability: coming with a twin alert system that integrates both an indicator and an audio player

• Multiple protection functions or mechanisms: including but not limited to the emergency stop buttons, bumpers, obstacle avoidance, and battery protection

• Compliance: CE/NRTL

In July, Hai Robotics will be attending CeMAT in Sydney to showcase a number of its innovative robotic solutions.

On display and for demo will be the newly launched solution, that encompasses Hai’s flagship ACR solution, HaiPick, along with the AMR-led solution, HaiFlex within the same operational grid. Attendees will also be able to learn more about Hai’s innovative micro-fulfilment solutions. Featuring a mini-AMR solution, Hai’s micro-fulfilment utilises both ACR and AMR technology to increase throughput, accuracy and is Hai’s highest density and throughput solution to date.

Visit Hai on Stand F16 to learn more about the latest robotic solutions to hit Australia and New Zealand.