Hai Robotics Launches the World's First Telescopic Lift ACR Reaching New Picking Heights

Hai Robotics launched the world's first telescopic lift ACR, HaiPick A42T, enabling an ultra-flexible warehouse. As a result, the robot realizes another breakthrough, creating an ultra-high storage density and flexible warehouse automation solution.

As a pioneer in autonomous case-handling robots (ACR), Hai Robotics launched the world's first telescopic lift ACR, HaiPick A42T, enabling an ultra-flexible warehouse.

HaiPick A42T robot is equipped with an intelligent telescopic lift function, which can flexibly cover a range from 0.25m to 6.50m making unreachable warehouse storage spaces accessible. Furthermore, this function suits various warehouses with irregular sizes.

As a result, the robot realizes another breakthrough, creating an ultra-high storage density and flexible warehouse automation solution.

Telescopic Lift ACR, HaiPick A42T

1. No need for modular customization with an intelligent telescopic lift

Compared with modular, customized robots, the HaiPick A42T robot has an intelligent telescopic lift function, extending its 3.6m body frame up to 6.5m, maximizing the use of warehouse space and realizing ultra-high and flexible storage.

2. 0.25m to 6.5m picking range

HaiPick A42T has made a significant breakthrough for warehouses by increasing the robot's picking height. The robot's minimum access range is as low as 0.25m, and the maximum goes up to 6.5m, covering more storage space and improving storage density.

3. High & Stable

Safety and reliability are critical factors in improving the quality of the robot. In addition, the height of HaiPick A42T is only 3.6m tall, enhancing the robot's running speed and stability. Simultaneously, it realizes the picking, handling, and sorting of bins on the 6.5m shelf, delivering the "3 highs", high stability, high efficiency, and high-density storage.

4. Customization that meets multiple needs

HaiPick A42T provides flexible customization options, which can customize the robot's height to meet each warehouse's different needs and apply it to a broader range of scenarios.

Countless Possibilities for All Kinds of Warehouse Requirements

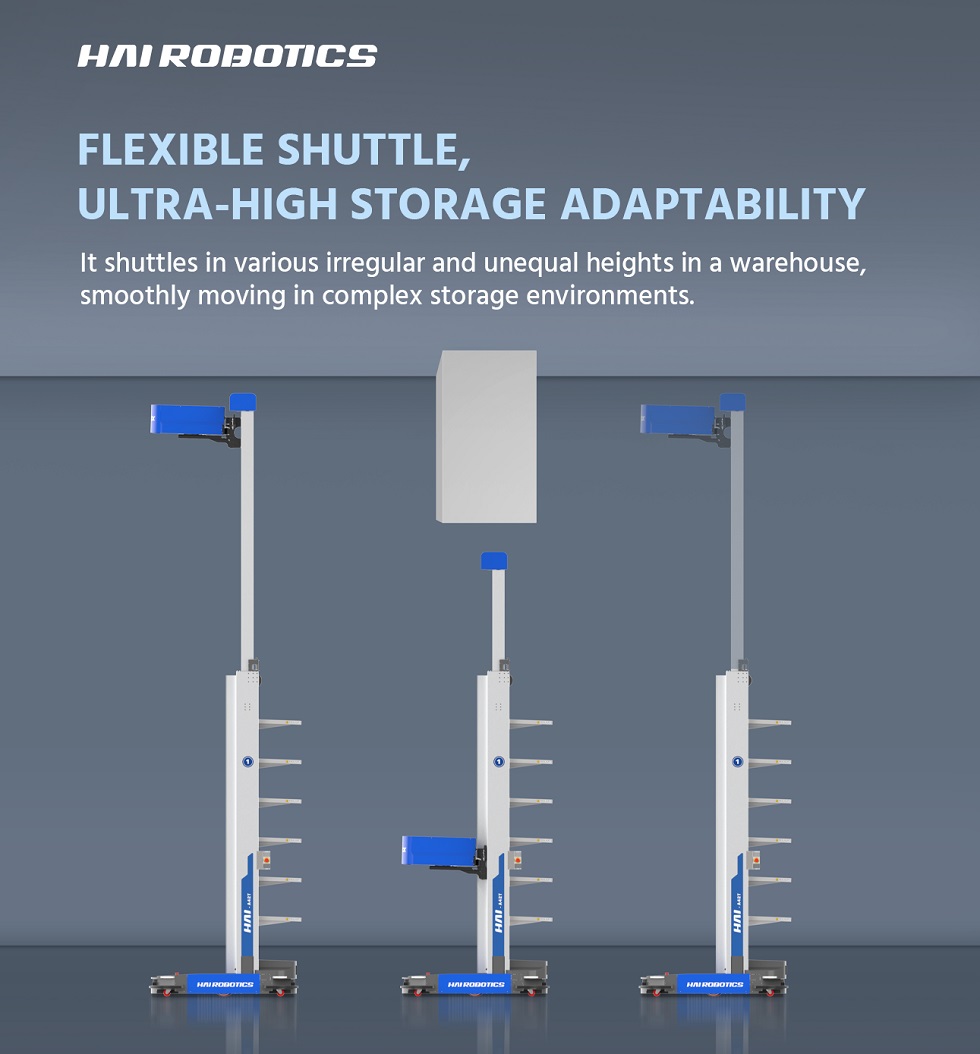

1. Intelligently adapt to irregular warehouses

HaiPick A42T further improves the storage adaptability, flexibly shuttles through various irregular and unequal heights of different warehouses, and smoothly responds to the complex warehouse environment caused by fire-fighting pipelines, building beams, etc. It reduces the threshold of warehouse automation transformation and exerts the storage density limit to empower more storage.

2. The same level of efficiency for different areas separated by the firing threshold

It is easy to obtain uneven operational efficiency between two areas separated by the firing threshold. The HaiPick A42T's unique attribute allows the robot to shuttle between two or more areas. As a result, warehouses can move robots from one side to another easily when needed. It delivers a flexible response to the high operational requirements of varying storage areas and realizes the mutual transfer of robots between areas, achieving the highest robot utilization rate.

3. A robot that can take elevators!

HaiPick A42T can now ride elevators, allowing free shuttle between floors, and covering a wider range of warehouse operations. In addition, it can realize the docking of warehouse areas and production lines on different floors, combining customized solutions to meet various customer needs.

4. Convenient transportation and rapid deployment

HaiPick A42T's "compact" body is more convenient to transport and handle, speeding up deployment, improving overall project implementation efficiency, and increasing efficiency for the customer.

HaiPick A42T robot results from a continuous focus on solving customers' pain points. It marks another innovative milestone for the company's ACR products, helping more companies realize storage automation transformation, increasing storage density, and creating ultra-high flexibility storage for every warehouse.

About Hai Robotics

Hai Robotics is a pioneer in autonomous case-handling robots (ACR). The company is committed to providing efficient, intelligent, flexible, and customized warehouse automation solutions through advanced robotics technology and smart algorithms and creating value for each factory and logistics warehouse. Hai Robotics focuses on the R&D and design of autonomous case-handling robot systems (ACR).

The company realizes the independent R&D of core elements such as robot body, bottom positioning algorithm, control system, robot scheduling, and intelligent warehouse management system, and has carried out global patent layout.

In 2015, the company developed HaiPick, the first autonomous case-handling robot system, and put it into commercial operation. Since then, it has been applied in 3PL, footwear, e-commerce, electronics, energy, manufacturing, medicine, and other industries. By using the HaiPick system, customers can realize warehouse automation transformation in a week, increase storage density by 80% - 130%, and improve workers' work efficiency by 3-4 times.