Bosideng

Apparel Warehouse

48,526

Storage Locations

3,000 cases

Outbound Efficiency Per Hour

99.9%

Picking Accuracy

Fast

Return on Investment

--Higher requirements to improve outbound efficiency

--High local labor costs; high labor turnover

--Standardized operations need to be automated

Our Solution

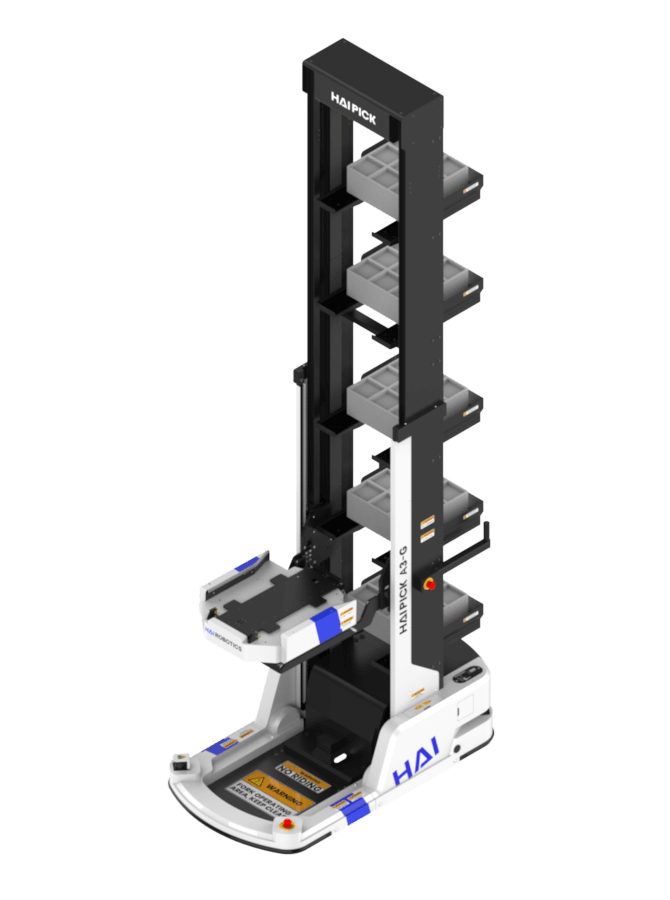

--Robot quantity & type: 87 units, A42N

--Charging stations:24

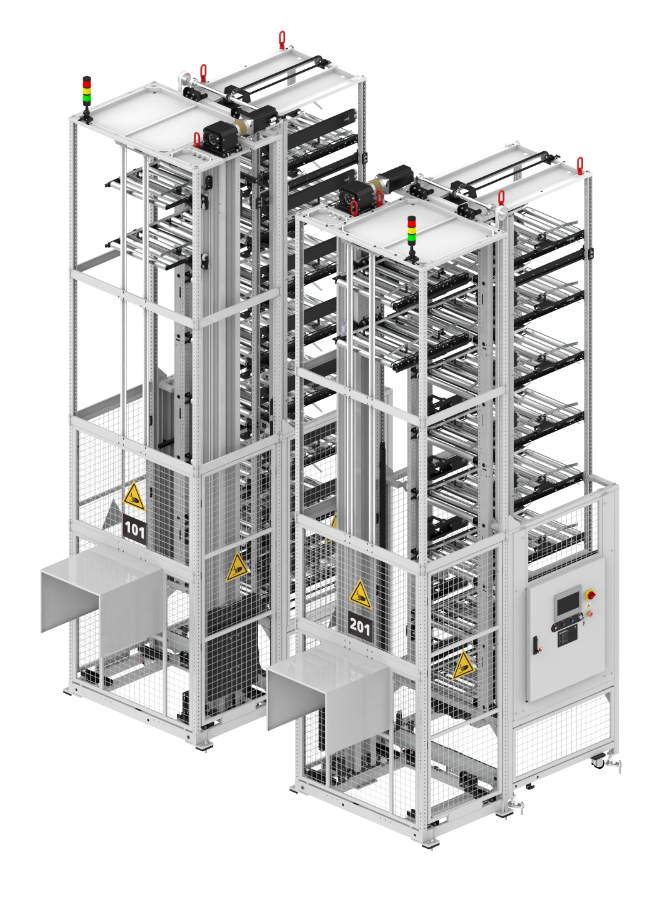

--Workstation type & quantity: 18 (10 on-conveyor picking workstations + 3 on-shelving picking workstations + 5 outbound HAIPORT-powered workstation)

--Storage unit type/size: tote 600mm(L)×400mm(W)×400mm(H)

--Shelving area: 7,000m², achieved 48,526 storage locations

--Excellent outbound efficiency: B2B area 3,000 cases/hour

--HAIPICK A42N, is perfectly meets the requirements of all sizes of cartons and totes

--5 HAIPORT workstations delivered high operation efficiency