The Common Challenges

-

Manual planning struggles to keep up.

When demand changes by the week, spreadsheets and static layouts can’t adjust fast enough.

-

Peak volume exposes inefficiencies.

Overflow inventory, walk-time delays, and re-slotting issues get magnified during peak.

-

There’s little time to test automation options.

Pilot programs take time—but peak season won’t wait. The window for experimentation is closing fast.

-

It’s hard to build a clear ROI case.

Even if the pain points are obvious, gaining leadership buy-in requires hard numbers and visual clarity.

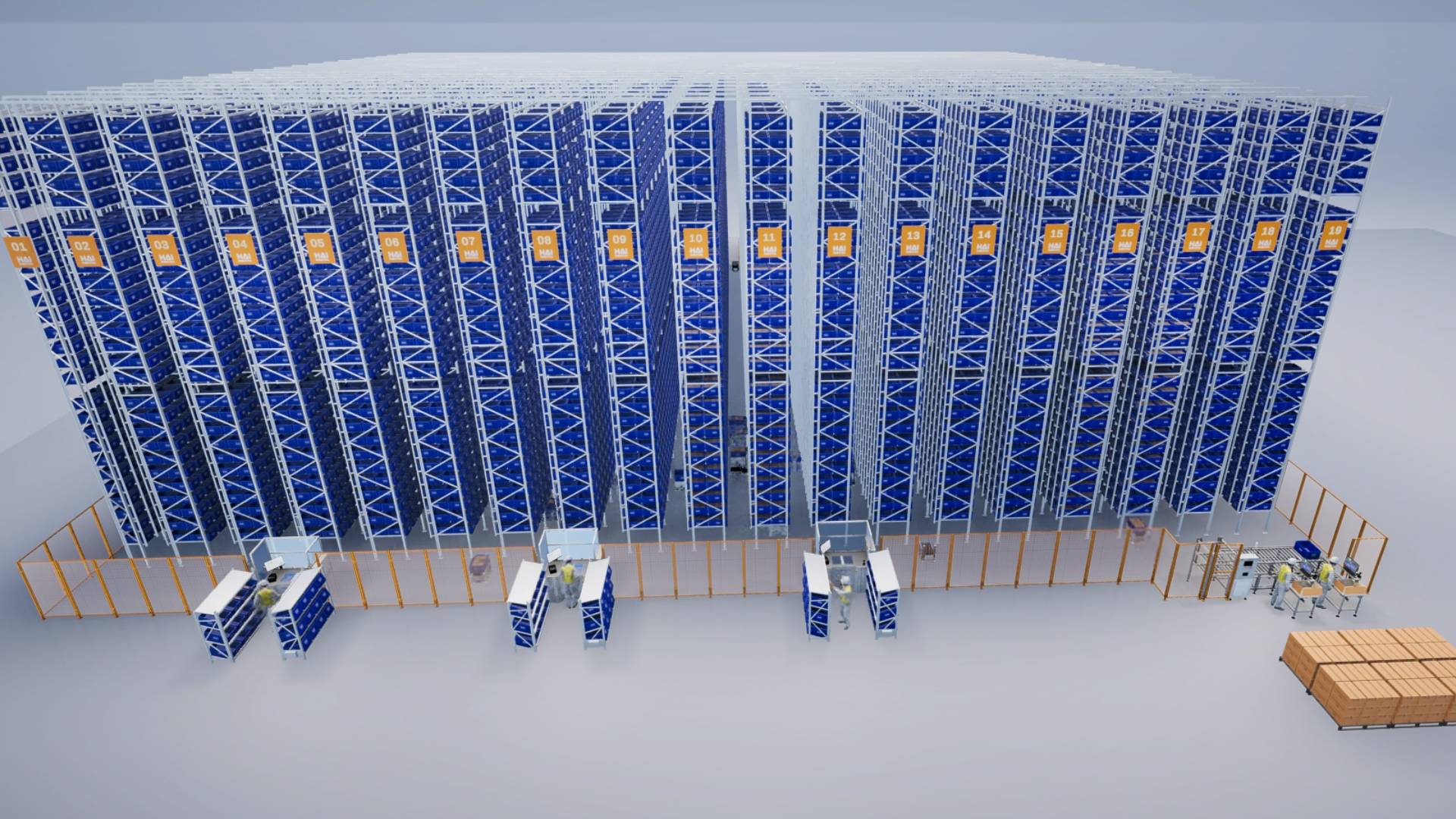

That’s where the Virtual Warehouse comes in

Whether you're planning for automation now or 12 months from now, our Virtual Warehouse helps you make confident, data-driven decisions.

Explore Without the Learning Curve

The Virtual Warehouse lets you experience how the system operates — without manuals, training, or technical prep. You’ll see the full workflow, interface, and operator tasks in context, making it easier to assess fit and plan for change.

Simulate Scalability Before You Invest

The Virtual Warehouse lets you explore how different layouts scale with your business. Test phased deployments, zone adjustments, or storage expansions before making changes in the real world.

Justify the Investment

The Virtual Warehouse simulations help you forecast performance, throughput, and payback before anything is installed. Build a business case based on real data — not assumptions — and move forward with confidence.

Request Your 1-on-1 Consultation

Do you want to discuss your logistics challenges and further explore how our automation solutions can optimize your operations?

Book a consultation with one of our specialists today.

Want to Learn More About Our Systems?

From high-density tote-to-person systems to flexible robot fleets for fast-moving items — Hai Robotics offers multiple automation systems to suit different warehouse types and business goals.

View the System Overview (PDF)