Award-Winning Goods-to-Person Automation

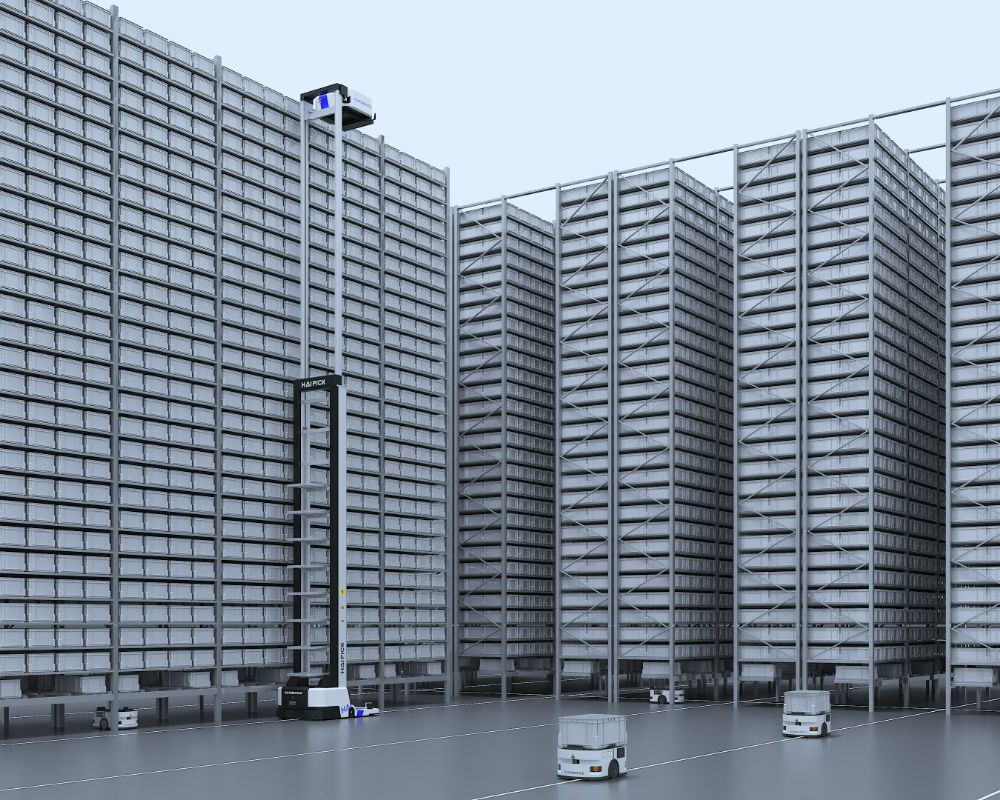

Our HaiPick Automated Storage and Retrieval Systems (ASRS) elevate the world's access to inventory by providing smart, fast, flexible, and efficient goods-to-person solutions that can accommodate any facility.

From small businesses to the world's biggest retailer, our advanced robotic systems are designed to adapt to your facility's unique needs — with proven results.

About HaiPick Systems

The family of HaiPick Systems are highly flexible Automated Storage and Retrieval Systems (ASRS) that seamlessly support evolving operational demands and business growth.

Built on a modular framework, HaiPick Systems allow for easy reconfiguration, expansion, and relocation. Each system is designed using pre-engineered robots and components from our catalog, enabling solutions engineers to customize a base model with the ideal system elements for your specific needs — delivering a tailored solution without the cost or complexity of full customization.

The HaiPick Systems are flexible Automated Storage and Retrieval Systems (ASRS) that support evolving operations and business growth. Built on a modular framework, they allow for easy reconfiguration, expansion, and relocation. With pre-engineered robots and components, solutions engineers can customize a base model to meet specific needs, offering tailored solutions without the cost or complexity of full customization.

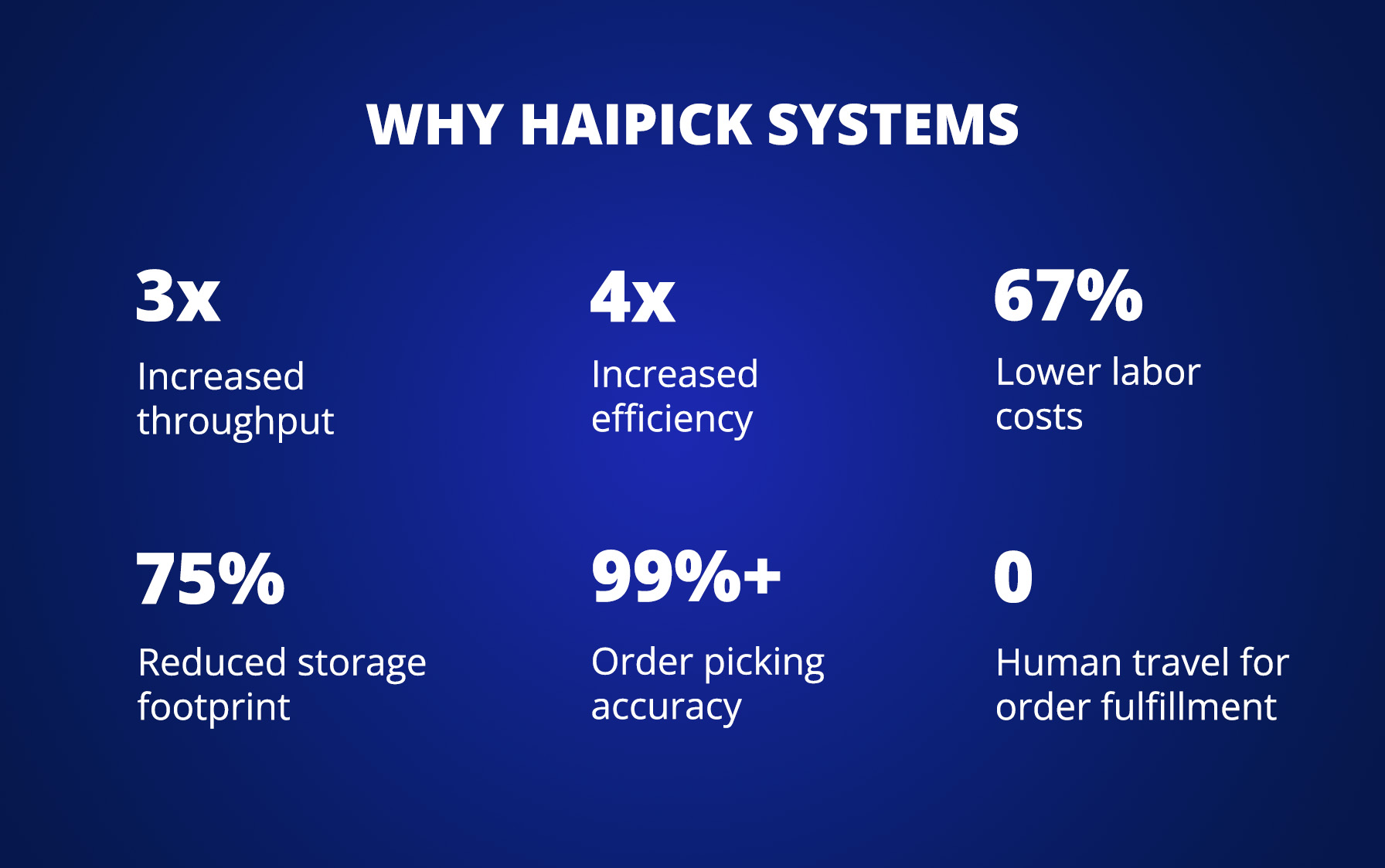

HaiPick System 1

Our essential goods-to-person solution. High-reach, high-density, and highly efficient inventory storage and retrieval for fast, accurate fulfillment that adapts and scales with your business.

- High-density vertical storage up to 12 meters (39+ feet)

- Up to 3x throughput for fast order fulfillment

- Labor cost reduction up to 67%

- 99%+ order pick accuracy with batch picking up to 9 containers per run

- 24/7 operating capability and easy integration with existing WMS/WES

- Flexible storage options with variable container types or no container if appropriate

HaiPick System 2

All the benefits of System 1 — with added bulk and mixed-type storage capabilities.

- Automated mixed goods-to-person picking or material-to-line operations for small/medium/large, bulk, and/or irregular items stored together

- High-density vertical storage up to 12 meters (39+ feet)

- Up to 6x increased efficiency, 5x reduced storage footprint, and 3x throughput

- Labor cost reduction up to 67%

- 99%+ order pick accuracy with batch picking up to 9 containers per run

- 24/7 operating capability and easy integration with existing WMS/WES

HaiPick System 3

Maximum storage density, speed, and flexibility for high-throughput applications.

- Extreme-density vertical storage up to 12 meters (39+ feet) and 43 totes per square meter

- Up to 3x throughput for fast order fulfillment

- High-speed Companion Bots drive fast-moving items for ultimate order responsiveness

- Labor cost reduction up to 67%

- 99%+ order pick accuracy with batch picking up to 9 containers per run

- 24/7 operating capability and easy integration with existing WMS/WES

The Robots

HaiPick's Autonomous Case-handling Mobile Robots (ACRs) integrate with industry-standard racking and containers for versatile, cost-effective goods-to-person operations, offering flexibility to store various container types and materials, reducing costs. Tailored to specific inventory and systems, ACRs can work together to enhance operational capabilities, and in some cases, products can even be stored without containers.

Industries

Our Partners

Hai Robotics has developed a refined global network of partners, providing local support and ensuring success to facilities with HaiPick Systems all around the world. Each of our partners brings a unique value and additional benefits to end users, helping to provide extended capabilities outside the HaiPick Systems, creating a vast selection of full warehouse solutions for facilities in all industries without limitations.

Contact Us

Hai Robotics Singapore

Address: 351 Braddell Rd, #01-01, Singapore 579713

Tel: +65 68022539

Email: info.sea@hairobotics.com