Automation Solutions for Fashion & Apparel Logistics

Fashion and apparel logistics are operating under unprecedented pressure. Shortened product lifecycles, expanding size and color matrices, and omnichannel fulfilment demands have transformed warehouses from cost centers into strategic enablers.

Today’s apparel operations must support rapid assortment changes, store-ready replenishment, and fragmented e-commerce orders - often from the same inventory pool and within the same facility. To stay competitive, fulfillment must become faster, more adaptable, and capable of evolving without structural overhaul.

Trusted by Industry Leaders

All Your Apparel Fulfillment Needs, Covered

Fast handling of complex assortments

Maintain speed and accuracy across a high SKU variety, frequent collection changes, and fragmented orders.

Store-ready and omnichannel fulfillment

Support sequenced store replenishment and e-commerce fulfillment from one unified inventory pool.

Returns reintegrated without disruption

Bring returned items back into available stock quickly to protect sell-through windows.

Higher capacity without higher cost

Scale throughput and storage within existing space and labor constraints.

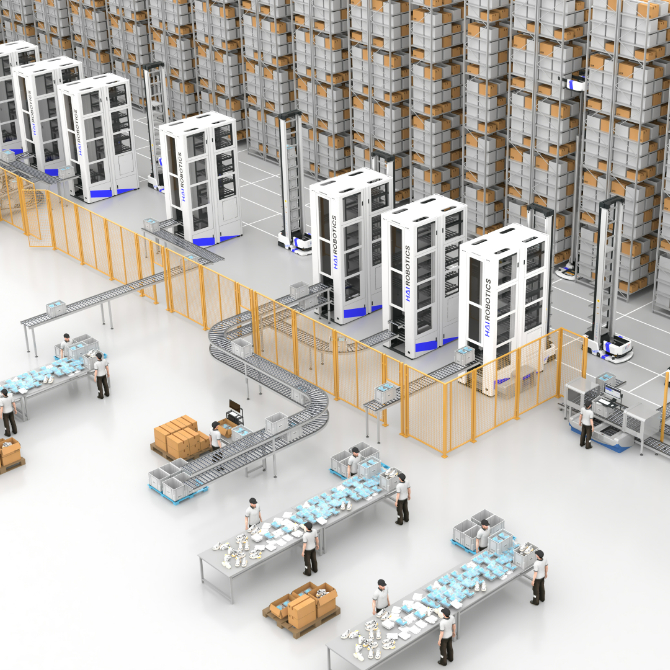

Fast Fulfillment for High SKU Volatility

Apparel assortments are constantly changing. HaiPick Systems are designed to keep fulfillment fast and accurate as SKU mix, size curves, and collections evolve week by week.

-

Goods-to-person fulfillment eliminates walking and reduces picking time, even for fragmented apparel orders.

-

Smart order grouping and sequencing logic support rapid processing of mixed SKU orders and store replenishment flows.

-

Consistent accuracy at scale, maintaining reliable order quality during seasonal peaks and new collection launches.

Store-Ready and Omnichannel Fulfillment from One System

Apparel warehouses increasingly serve two opposing flows: precision-driven store replenishment and fast, unpredictable e-commerce fulfillment. HaiPick enables both—without splitting inventory or workflows.

-

Sequenced picking for store-ready delivery, aligned with size curves, color groupings, and merchandising logic.

-

Unified inventory pool serving B2B and B2C orders with equal service levels.

-

Flexible fulfillment logic that adapts daily to shifting channel priorities without reconfiguration.

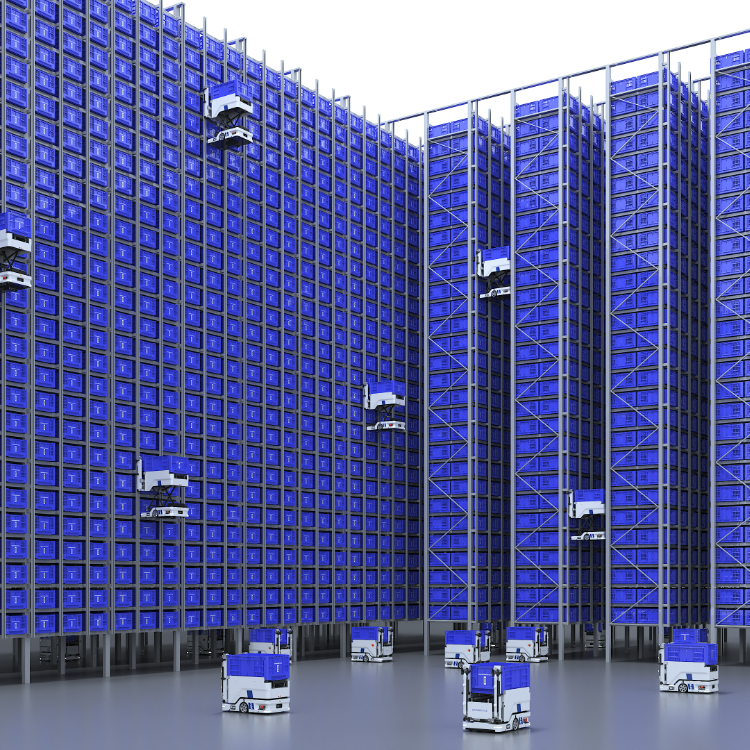

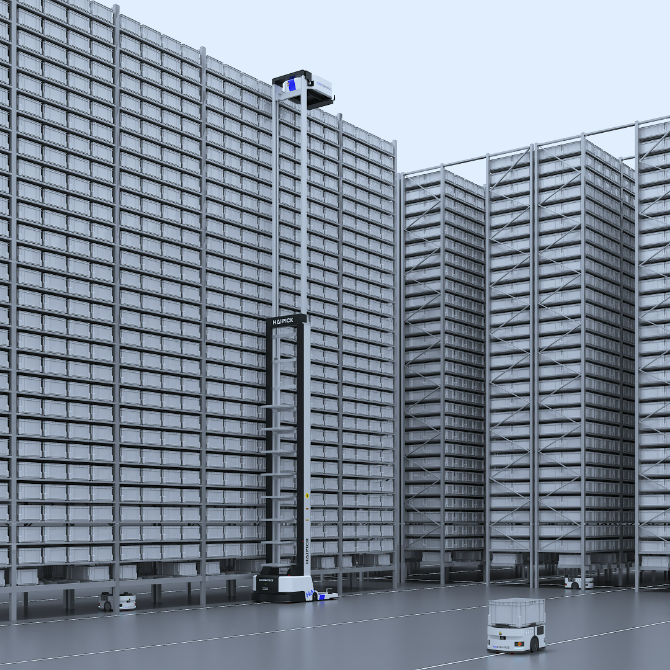

Higher Capacity with Lower Operating Cost

Space and labor constraints are structural challenges in apparel logistics. HaiPick increases capacity and stabilizes performance within the footprint and workforce you already have.

-

Vertical storage up to 10–12 meters unlocks high-density capacity without expanding buildings or adding mezzanines.

-

Consistent throughput with smaller teams, enabled by simplified tasks and goods-to-person workflows.

-

Predictable performance at scale, maintaining fast order cycles and high accuracy during peaks.

Built to Evolve with Fashion Cycles

Fashion growth rarely follows a straight line. HaiPick Systems are engineered for continuous adaptation, allowing apparel operations to scale and reconfigure as the business evolves.

-

Modular scalability, adding robots, racks, or workstations independently as assortments and volumes grow.

-

Fast deployment options, including HaiPick Climb for rapid go-live in brownfield or fast-growth environments.

-

Future-ready architecture that supports phased expansion without downtime or structural redesign.

HaiPick Solutions for Automated Apparel Warehouses

Desigual

Viladecans Distribution Center

7,980

Storage Locations

30,000 Units/day

Daily Delivery Efficiency

650 Cartons/hour

Throughput

3-4 Times

Improved Warehouse Efficiency

60-80%

Lower Operational Costs

99.99%

Picking Accuracy

This saves us a lot of time and money! It is very easy to manage this type of solution, both in terms of implementation as well as use by staff. Our teams’ experience with the integrator and Hai Robotics has been consistently positive.

This saves us a lot of time and money! It is very easy to manage this type of solution, both in terms of implementation as well as use by staff. Our teams’ experience with the integrator and Hai Robotics has been consistently positive.

Scalpers

Guillena Logistics Hub

100,000

double-deep storage locations

250

boxes per hour throughput

4,500

orders shipped in 5 hours

60%

warehouse footprint decrease

the scalability of the system, which allows both the expansion of storage capacity and the incorporation of new vehicles. Automation increases the speed of order preparation, compensates for the shortage of skilled labor, and minimizes errors, thus improving service quality and reducing costs.

the scalability of the system, which allows both the expansion of storage capacity and the incorporation of new vehicles. Automation increases the speed of order preparation, compensates for the shortage of skilled labor, and minimizes errors, thus improving service quality and reducing costs.

New Wave Textiles

Utrecht Warehouse

84,832

Storage locations (phase 1)

30%+

Storage capacity increased

532

Load carriers per hour designed capacity

99%+

Order picking accuracy

We are excited to see our warehouse operations transformed with HaiPick System 3. The system delivers the efficiency and scalability we need to continue serving our customers at the highest level.

BOOT BARN

Kansas City Distribution Center

2x

Storage density

100%

Picking accuracy

50%

Lower labor costs

250%

Increased efficiency

Hai Robotics helped us achieve the throughput and capacity that we needed to support our 400 stores nationwide.

Download

Explore your future apparel warehouse

Discover how Hai Robotics can transform your apparel storage, improve warehouse garment handling, and unlock flexible storage solutions tailored to your business.