Grocery Automated Warehouse

The grocery industry is in the midst of transformation, presenting new challenges for supermarkets, hypermarkets, discount stores, convenience retailers, and e-grocery platforms. From the demand for affordable food to diverse in-store experiences and seamless fulfillment, the industry faces ever-increasing expectations. In this dynamic landscape, traditional methods struggle to overcome obstacles such as labor costs, volatility, SKU increases, and seasonal fluctuations.

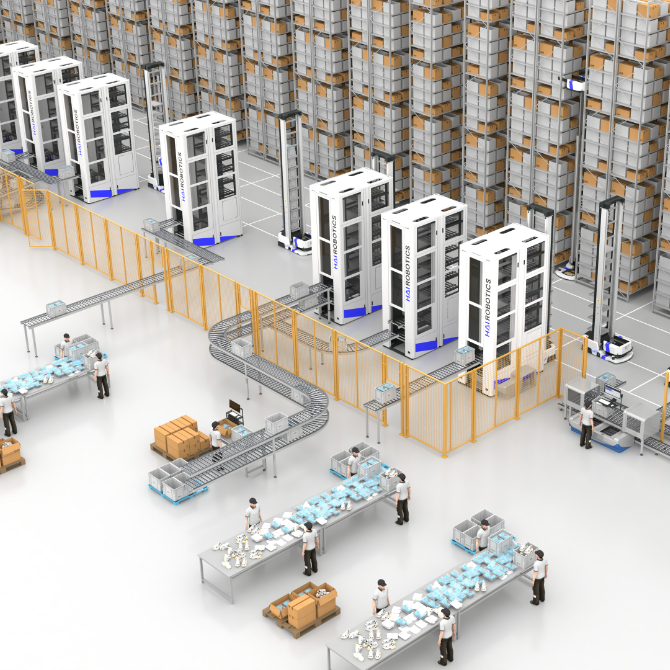

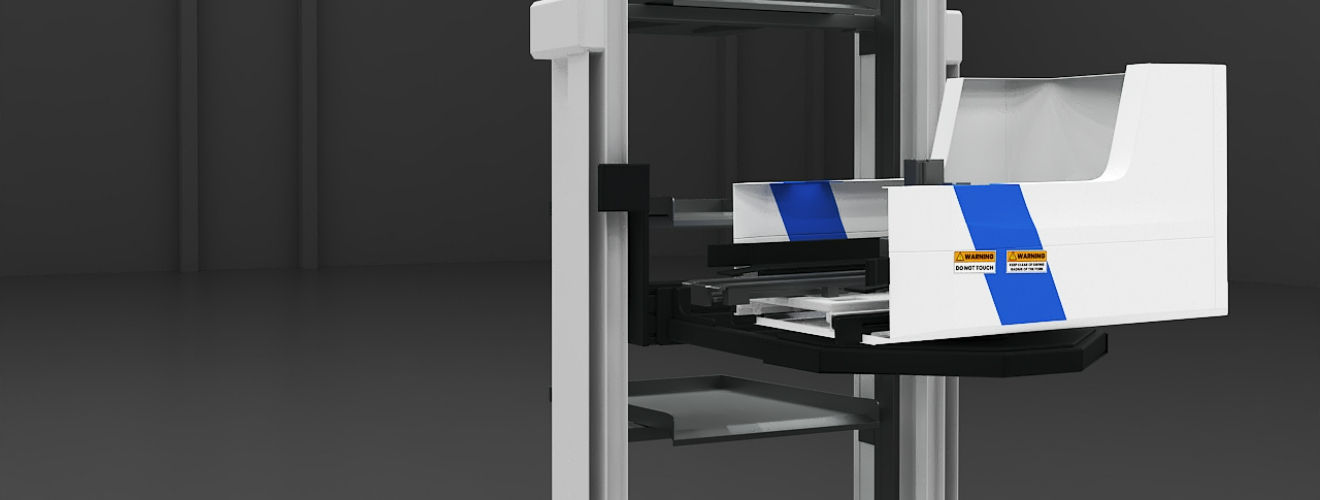

Discover the power of our ACR solutions (Autonomous Case-handling Mobile Robot) – your key to conquering the challenges of modern grocery fulfillment. Embrace automation and technology, scale systematically, and meet high volatility in customer demands head-on.

Unlocking Grocery Fulfillment with ACR: Your Future-Ready Solution

400%

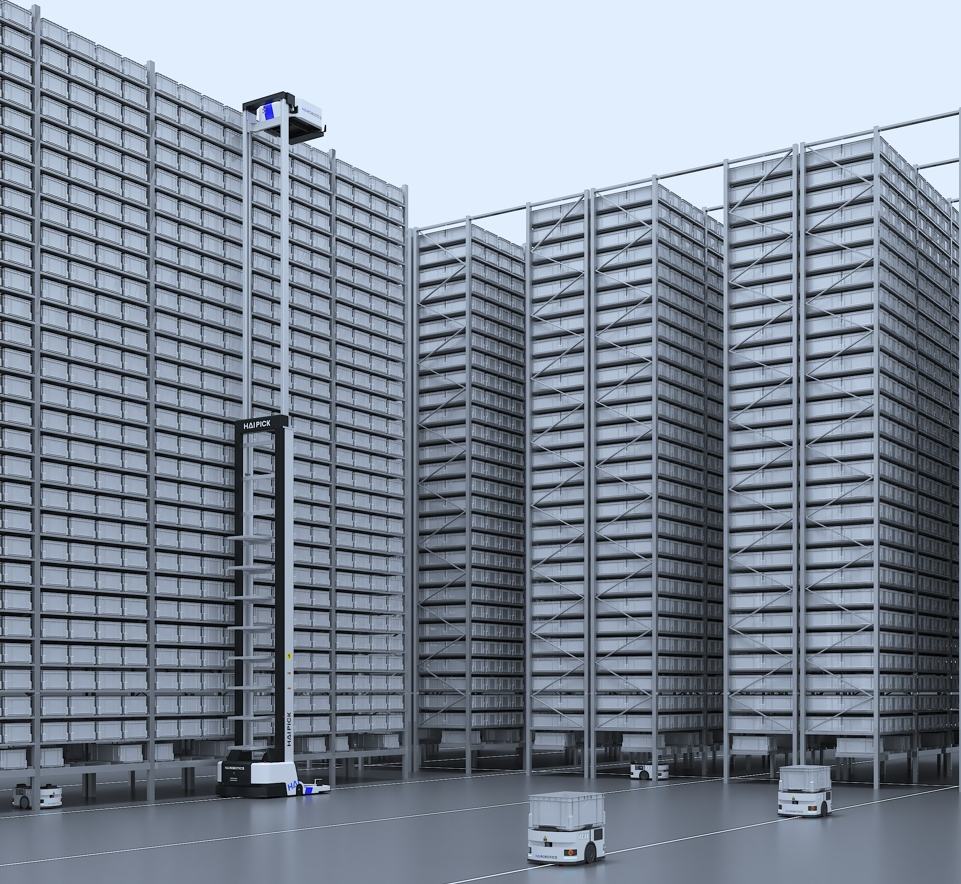

Increase storage density by 80-400%

3-4 Times

Increases picking efficiency by 3-4 times

99.99%

Achieve picking accuracy of 99.99%

High ROI

Cost-effective technology with High ROI

What our ACR solution offers:

Flexibility for Future-Proofing

Adapt to your evolving order profiles, SKU numbers, and load requirements.

Optimised Productivity

Slash cost per order line, reduces FTE dependency, and obtain rapid ROI.

Efficiency and Precision

Ensure speedy order fulfillment for fragmented orders, shorter lines, and growing SKU numbers while maintaining a remarkable 99.99% picking accuracy, and enable seamless same-day and next-day deliveries.

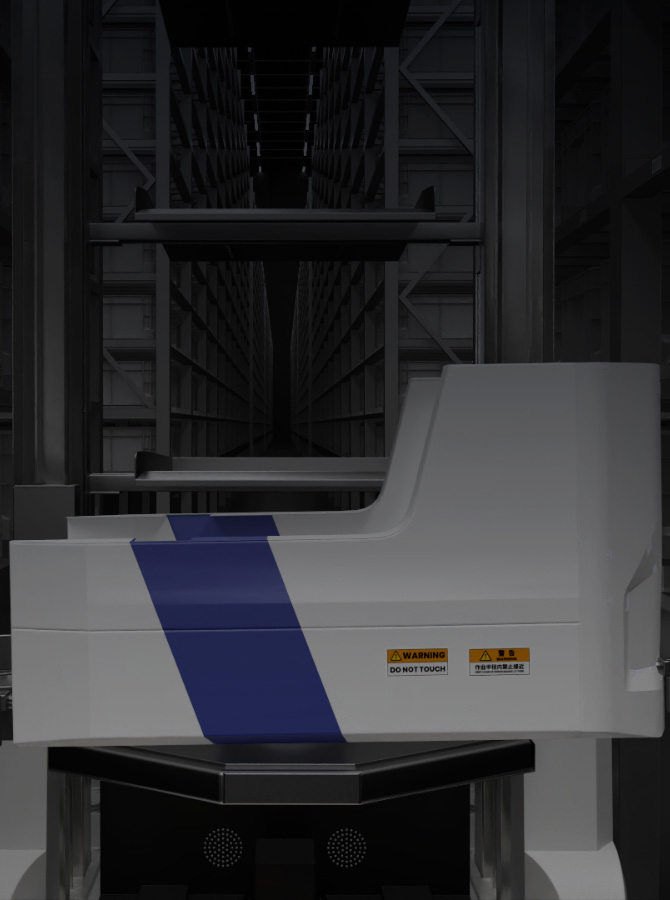

Enhanced Storage Density

Maximize storage density and height, making efficient use of your warehouse space.

For Supermarkets

Flexibility becomes your power. Our solution adapts to your evolving order profiles, SKU numbers, and load requirements, future-proofing your operations. With unmatched picking accuracy, quick deployment, scalability, and system redundancy, we ensure your operations are efficient and future-ready.

For Discount Stores

Efficiency takes center stage. Our solution slashes cost per order line, reduces FTE dependency, and offers a rapid ROI, optimizing your productivity like never before.

For E-grocery

Agility and flexibility define success. Our ACR Solutions ensure your operations keep pace with fragmented orders, short order lines, and SKU increases. Achieve seamless same-day and next-day deliveries, while optimizing storage density and height. For e-grocery operations of traditional retailers, we're here to help you make the most of your spaces and be closer to your consumers than ever before.

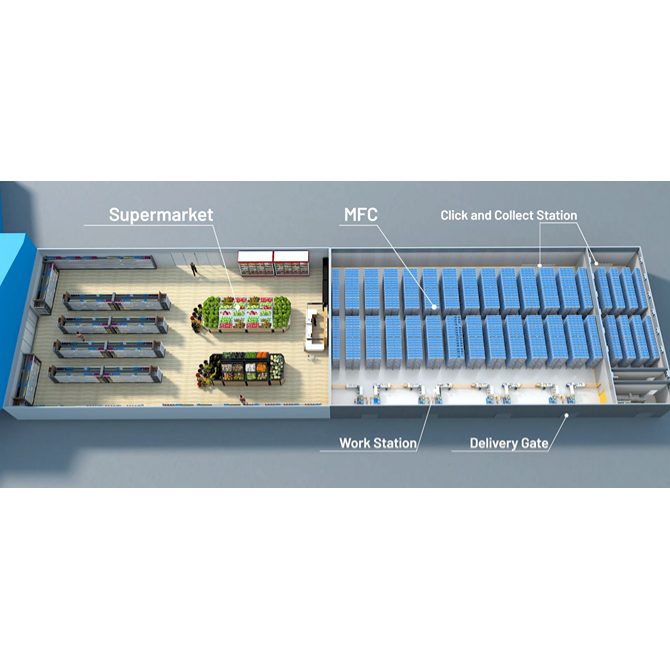

Introducing ACR-based MFC Solution

Our MFC (Micro-fulfillment Center) ACR-based solution can achieve:

-

Close proximity maximises customer convenience

-

Increased handling agility provides faster order response rates

-

Optimises existing storage space, even in hyper-urban settings

-

Reduces distribution, rental/real estate, picking & packaging, and labour costs

-

Easy-to-deploy and user-friendly technology and software system

-

Customizable systems to scale up or down due to consumer demand

-

Safely operates in three temperature zones (ambient, chilled & frozen)

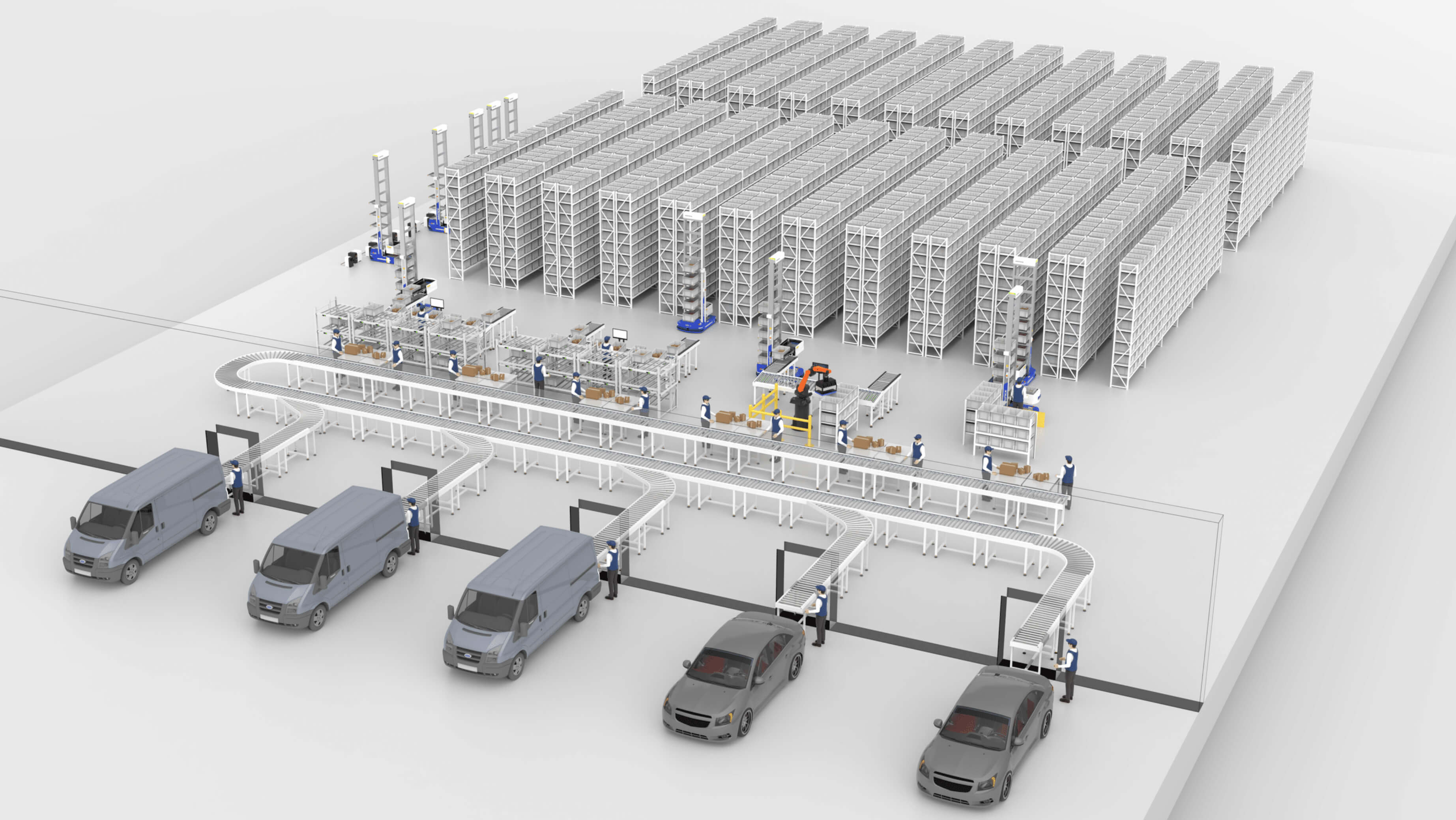

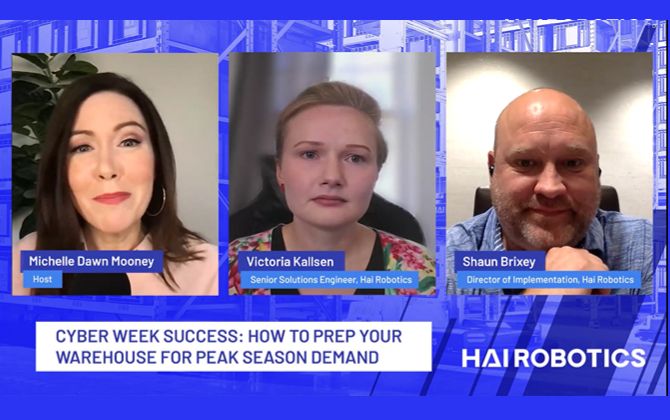

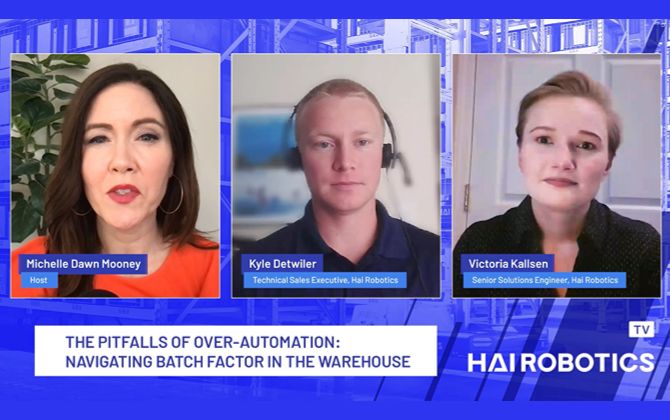

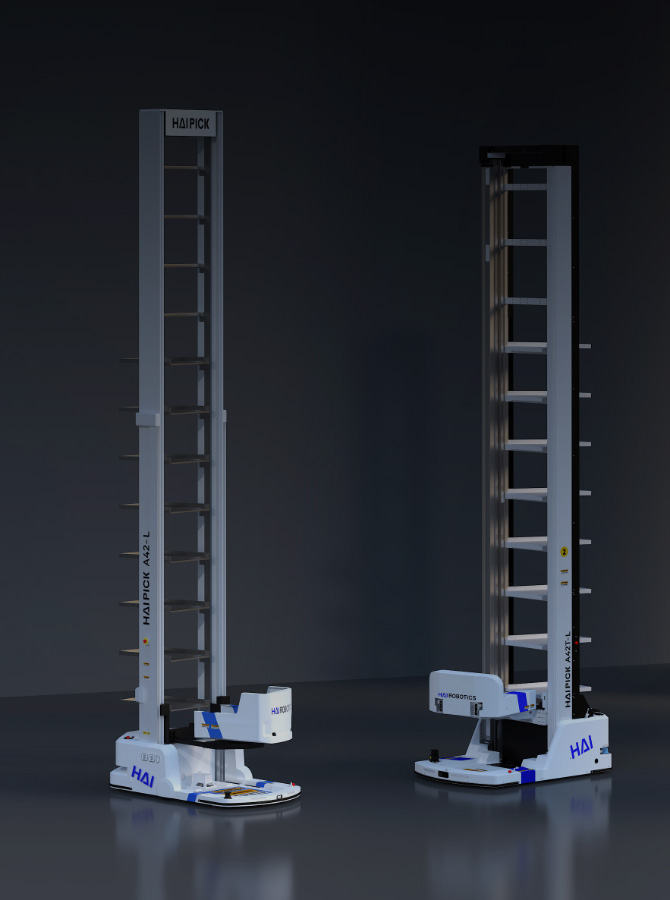

Large Online Retailer

Cross-border E-commerce Warehouse

42,000

storage locations

1,500

cases/hour system picking efficiency

99.99%

picking accuracy

The company mainly engages in cross-border e-commerce. After a successful first project using the HaiPick system, the company decided to implement the solution to power their first semi-automated warehouse in Lutterworth, UK. The equipment included CE-certified HaiPick robots and conveyors.

Downloads