Automotive Warehousing Solution

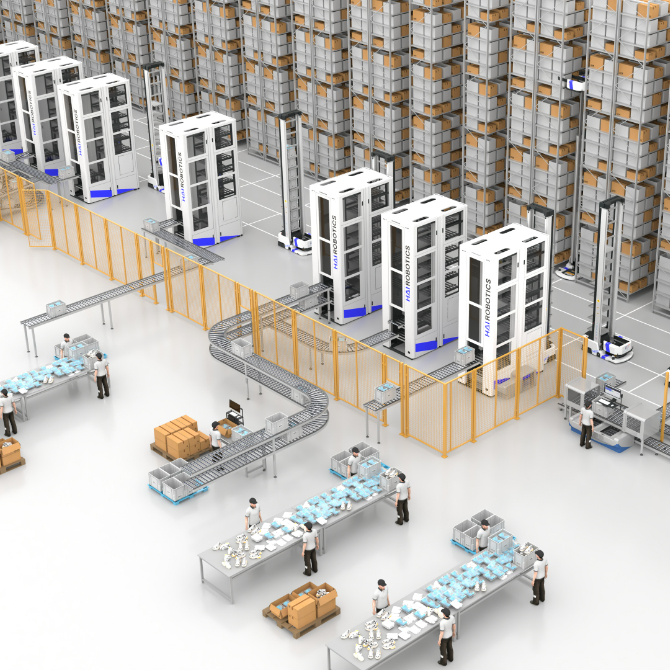

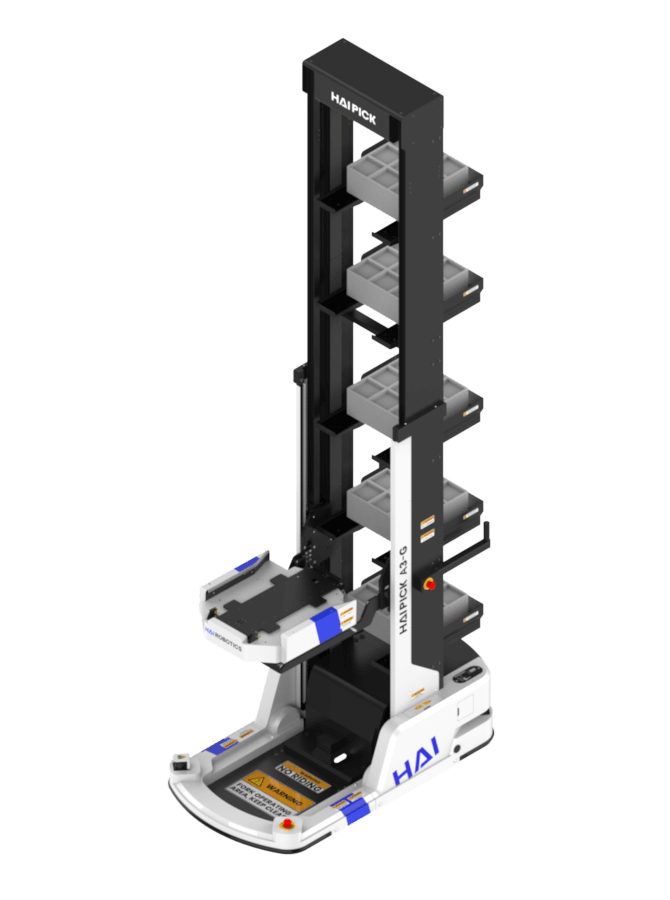

The diversification of order-driven production and rising labor costs are posing significant challenges to the traditional mode of warehousing logistics. In response, a robotics-based automotive warehousing solution has emerged at the case handling level.

Hai Robotics has transformed the traditional manual operation mode by making major advancements in efficiency, cost savings, and flexibility. This innovation is propelling the automotive industry's logistics sector into a new era of automation, intelligence, and digitization.

Highlights

178%

Increase space utilization rate by 178%

172%

Increase picking efficiency by 172%

50%

Cost savings of 50% in manual material preparation

Our Values

Automation Storage for Multi Dimension Case & Material

Realize Visualization & Digitization of the Warehousing Operation

Intelligent Scheduling, Continuous Empowerment of Dynamic Storage Location

Effectively Improve Ergonomics, Reduce Training Costs and Improve Staff Stability

Geely LYNK&CO

Assembly Shop KLT Warehouse

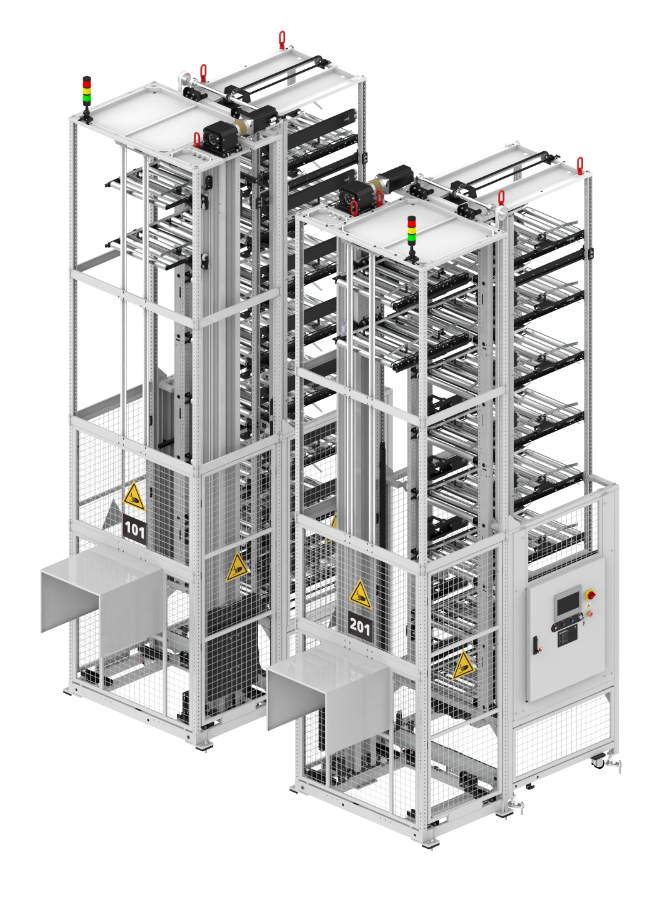

100 totes/h

Conveyor Inbound Workstations Efficiency

600 totes/h

Fast-inbound Workstations Efficiency

99.9%

Picking Accuracy

"The use of Hai Robotics’ ACRs has greatly improved the efficiency of warehouse picking. Geely achieved a more refined management of multiple SKUs and met the factory's just-in-time production requirements. Additionally, the high utilization of storage space further increased the storage density."

"The use of Hai Robotics’ ACRs has greatly improved the efficiency of warehouse picking. Geely achieved a more refined management of multiple SKUs and met the factory's just-in-time production requirements. Additionally, the high utilization of storage space further increased the storage density."

SAIC GM Wuling (SGMW)

Assembly Shop KLT Warehouse

10,752

Storage locations within an 1100㎡ warehouse

660 cases/h

Increased inbound & outbound efficiency

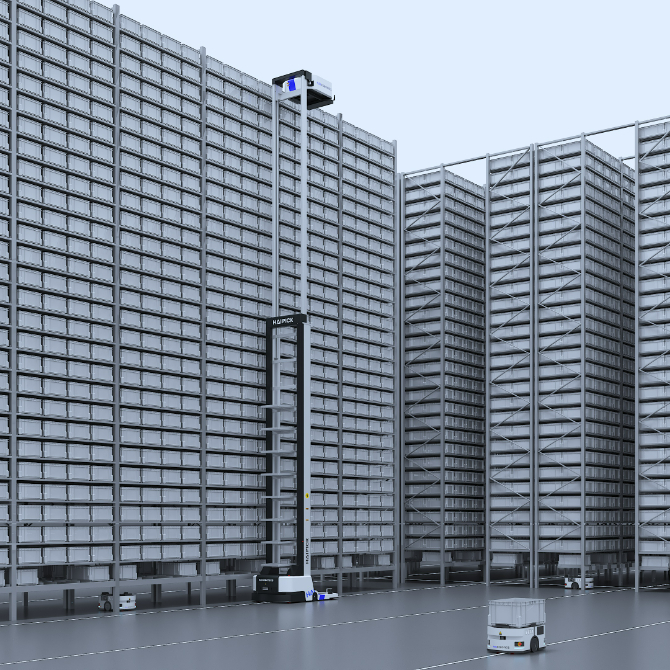

5.5 meters

Utilized full vertical storage space

The current intelligent system solution, whether regarding efficiency or storage density metrics, is a substantial improvement in production requirements.

Automotive Electronics Project

Raw Material Warehouse

2,960

Storage Locations

99.9%

Picking Accuracy

Fast

Return On Investment

"Hai Robotics products and solutions have received high praise in the industry, and that’s why we choose Hai Robotics."

Downloads

Download our latest industry report and learn how ACR powers different sectors. You'll learn exactly what ACR is and why it's different and so powerful.