JNBY Group

Apparel Warehouse

88,000

Storage Locations

100 times

Increase Warehousing Efficiency

5,000 pcs

Comprehensive Warehouse Efficiency Per Hour

99.9%

Picking Accuracy

--Unbalanced operation (peak B2B end of quarter returns, daily store returns, peak returns after online promotion)

--Complex return operation (massive SKU return, multi-level sorting on shelves, single SKU and single storage)

--The return inventory cycle is slow (the peak return inventory is easy to squeeze, and the satisfaction rate of B2C inventory on sale is low

Our Solution

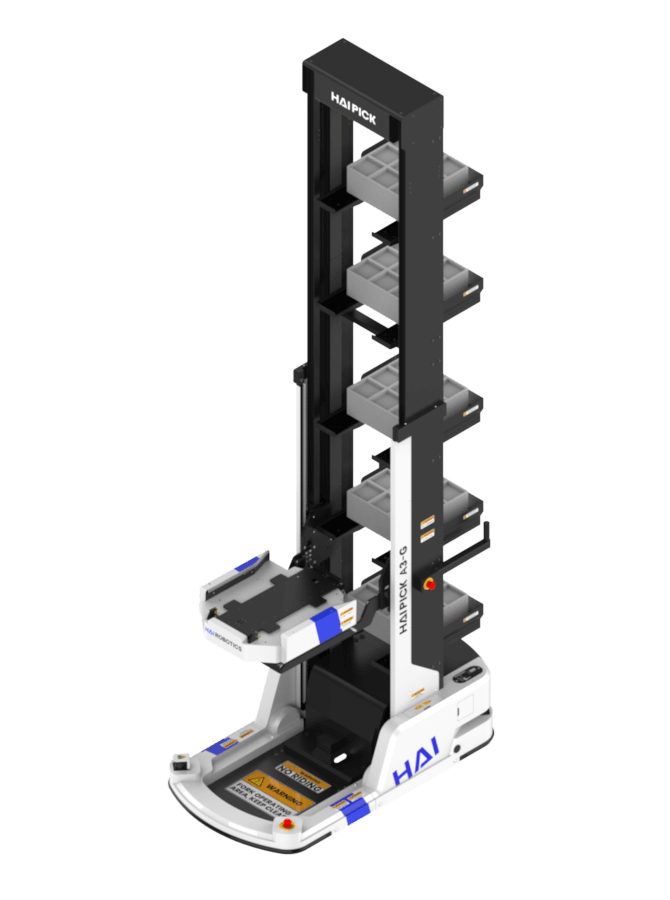

--Robot quantity & type: 56 units, A42L

--Charging stations:19

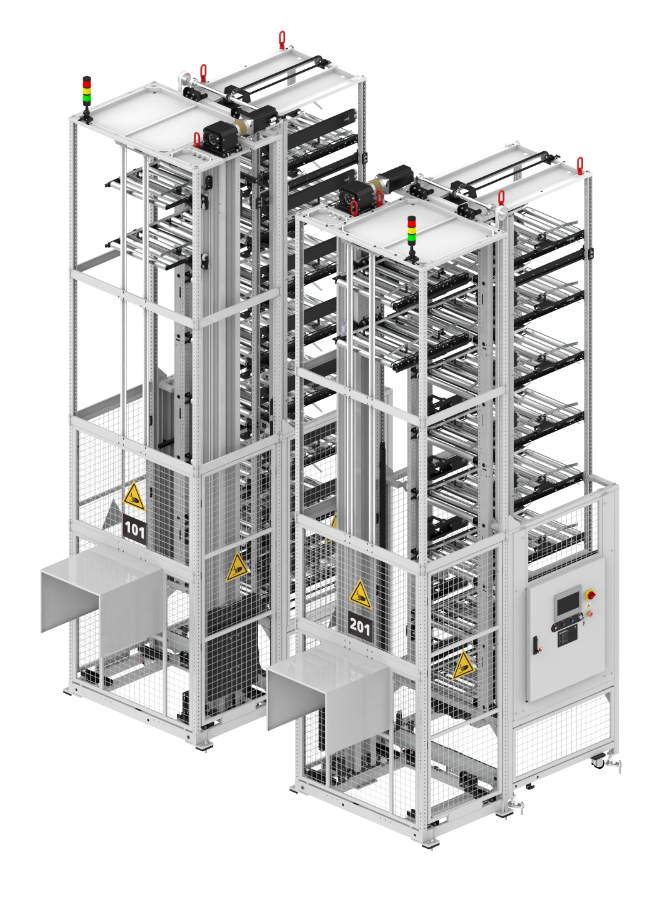

--Workstation type & quantity: 7 HAIPORT loaders + 7 HAIPORT unloaders

--Shelving height: 2780mm

--Storage unit type/size: Tote 600mm(L)×440mm (W)×280mm (H)

--Warehouse area: 16,000m²; Storage area: 12,400m²; More than 88,000 storage locations: add storage locations in the existing warehouse

--The comprehensive efficiency of warehousing increased from 50 pieces/hour to over 5,000 pieces/hour: the comprehensive efficiency of warehousing increased by more than 100 times, greatly reducing the warehousing time

Downloads

Download our latest industry report and learn how ACR powers different sectors. You'll learn exactly what ACR is and why it's different and so powerful.

Download the white paper and discover what industry leaders think about the future of warehouse automation, the impact it would have on workforces and sustainability, the risks facing the industry, and the potential avenues for collaboration to drive forward progress.