3PL Warehouse Automation Solution

As e-commerce continues to grow and supply chains become more complex, 3PL warehouse operations are under increasing pressure to deliver faster, more cost-effective, and more flexible logistics services. Managing diverse client requirements, fluctuating order volumes, and value-added services within limited warehouse space has become a daily challenge for third-party logistics providers.

Many 3PL warehouses still struggle with low storage density, labor-intensive logistics processes, and rising operational costs. At the same time, customers expect faster fulfillment, reduced shipping times, and a seamless customer experience, putting even more strain on existing warehouse infrastructure.

In an environment defined by labor shortages, rising rents, and increasing competition, 3PL providers need intelligent automation solutions that help them scale efficiently, optimize warehouse space, and save money while maintaining service quality.

Hai Robotics delivers flexible 3PL warehouse automation solutions designed to support modern fulfillment processes, improve inventory warehouse management, and enable logistics service providers to grow profitably.

50%

Combined labor & rental savings of 50%

3-4 Times

Increase inbound & outbound efficiency by

2-3 Years

ROI 2-3 years

Trusted by Industry Leaders

Key Challenges in 3PL Warehouse Operations

Operating a 3PL warehouse means balancing efficiency, flexibility, and cost control often across multiple clients and service models.

Common challenges include:

-

Managing diverse fulfillment processes across different customers

-

Limited warehouse space and rising rental costs

-

Labor shortages impacting picking, replenishment, and value-added services

-

Complex logistics processes requiring fast adaptation

-

Difficulty integrating automation with existing warehouse management systems (WMS)

Without scalable automation, these challenges can negatively impact profitability, service levels, and overall customer experience.

Automated 3PL Warehouse Solutions Built for Flexibility

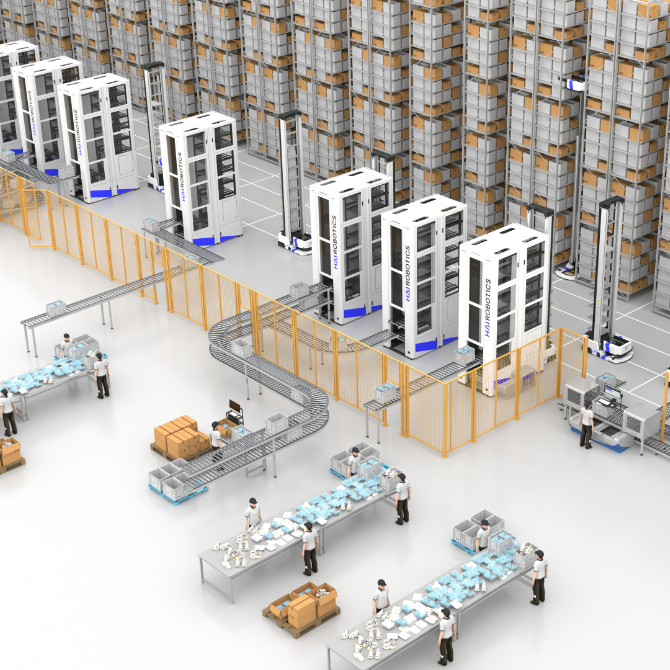

Hai Robotics offers a modular, goods-to-person automation approach that adapts to the dynamic needs of 3PL warehouses.

Our solutions support:

-

Multi-client inventory warehouse management

-

Flexible storage and picking strategies

-

Seamless integration with existing WMS platforms

- Rapid deployment without heavy infrastructure changes

By automating core logistics processes, 3PL providers can reduce reliance on manual labor, optimize warehouse space, and improve operational consistency across services including fulfillment, returns, and value-added operations.

Benefits of Hai Robotics’ Automated 3PL Warehouse Solution

- 50% Combined Labor & Rental Savings

By increasing storage density and reducing manual handling, Hai Robotics helps 3PL warehouses save money on labor and warehouse rental costs — delivering combined savings of up to 50% while maintaining high service levels.

- 3-4x Increase in Inbound & Outbound Efficiency

Automated picking, replenishment, and put-away processes enable 3PL operators to process higher order volumes with greater speed and accuracy. This results in a 3 to 4 times increase in inbound and outbound efficiency, even during peak periods.

- ROI Within 2–3 Years

Thanks to scalable deployment and reduced operational costs, many 3PL customers achieve a return on investment within 2 to 3 years, making automation a sustainable long-term strategy rather than a short-term fix.

Highlights of Hai Robotics’ 3PL Automation Solutions

- Flexible Solutions for Various Business Scenarios

Hai Robotics solutions are designed to support a wide range of 3PL business models — from e-commerce fulfillment to B2B distribution and value-added services. The system easily adapts to changing client requirements without disrupting ongoing operations.

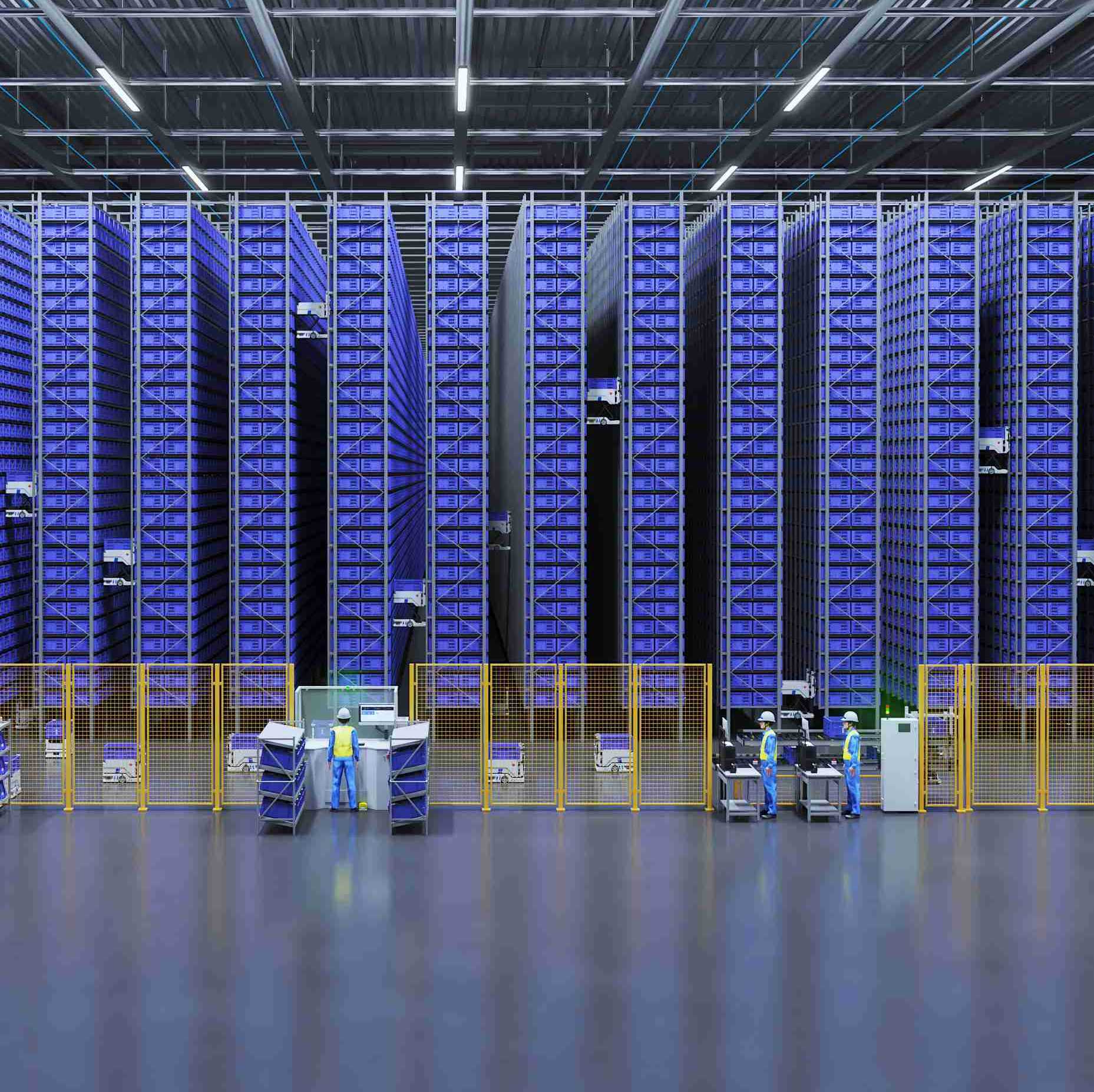

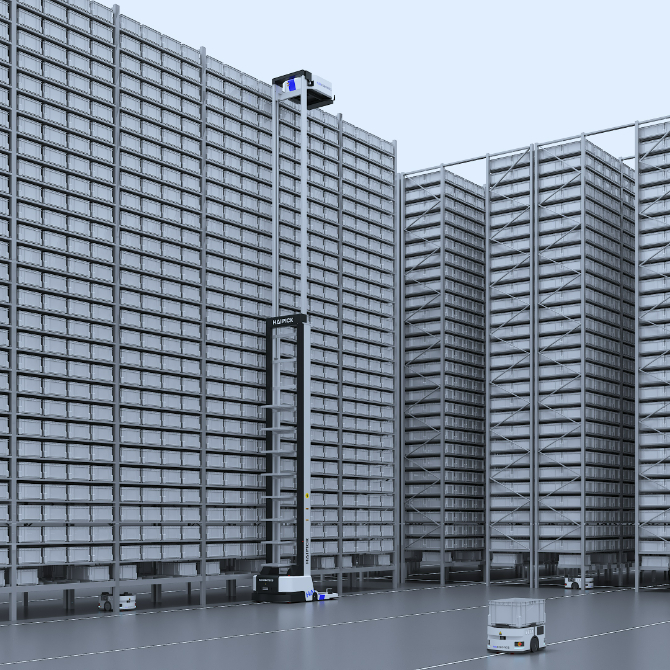

- Increase Storage Density and Reduce Warehouse Rental Cost

By maximizing vertical warehouse space and enabling high-density storage, Hai Robotics helps 3PL providers significantly improve warehouse space utilization — reducing the need for costly warehouse expansion or relocation.

- Ergonomic, User-friendly Operation

Goods-to-person workflows reduce operator walking distances and physical strain. This improves workforce productivity, lowers training requirements, and supports safer, more ergonomic working conditions.

- High Picking Efficiency with Accuracy Up to 99.99%

Automated picking and intelligent system control ensure consistently high accuracy rates up to 99.99%, helping 3PLs reduce errors, minimize returns, and enhance customer experience.

- Easy to Deploy and Upgrade

Hai Robotics solutions are modular and scalable, allowing 3PL providers to deploy automation quickly and expand capacity over time. This makes it easier to respond to new customer contracts, seasonal peaks, and evolving logistics processes.

Supporting End-to-End Fulfillment and Value-Added Services

Modern 3PL operations go beyond basic storage and shipping. Hai Robotics enables efficient handling of services including kitting, labeling, returns processing, and customized fulfillment workflows.

By streamlining fulfillment processes and reducing shipping times, 3PL providers can improve service quality while maintaining cost control and ultimately delivering a better customer experience for their clients.

A Smarter Way to Optimize 3PL Warehouse Operations

With intelligent automation, flexible system design, and seamless WMS integration, Hai Robotics helps 3PL providers modernize their logistics operations without sacrificing adaptability.

Whether your goal is to expand capacity, reduce shipping costs, or enhance fulfillment performance, Hai Robotics offers a future-ready 3PL warehouse automation solution that grows with your business.

HaiPick Solutions for Automated 3PL Warehouse

JD Logistics

California Distribution Center

100,000+

SKUs Currently Managed

240%

more vertical storage

641.7

outbound orders / hour

JD Logistics' California distribution center maximizes throughput and operational efficiencies with Hai Robotics' ASRS solution.

Winit

Cross-border E-commerce Warehouse

50,000

daily processed pieces

99.99%

picking accuracy

3-4 times

improved warehouse efficiency

These smart robots have well met our expectations. We picked Hai Robotics as our autonomous robot supplier among several other companies because it is one of the first developers. Its system has better stability than that of others, and its staff is professional.

These smart robots have well met our expectations. We picked Hai Robotics as our autonomous robot supplier among several other companies because it is one of the first developers. Its system has better stability than that of others, and its staff is professional.

Download Resources

The main trends and challenges in 3PL fulfilment.

Innovative and flexible automation solutions that meet the needs of 3PL providers, helping them achieve unprecedented efficiency and storage density.