SF-DHL Supply Chain

Apparel Warehouse

7 Days

Complete Deployment

20 Times

Improved Inbound Efficiency

160%

Storage Density

3.5 Times

Improved Outbound Efficiency

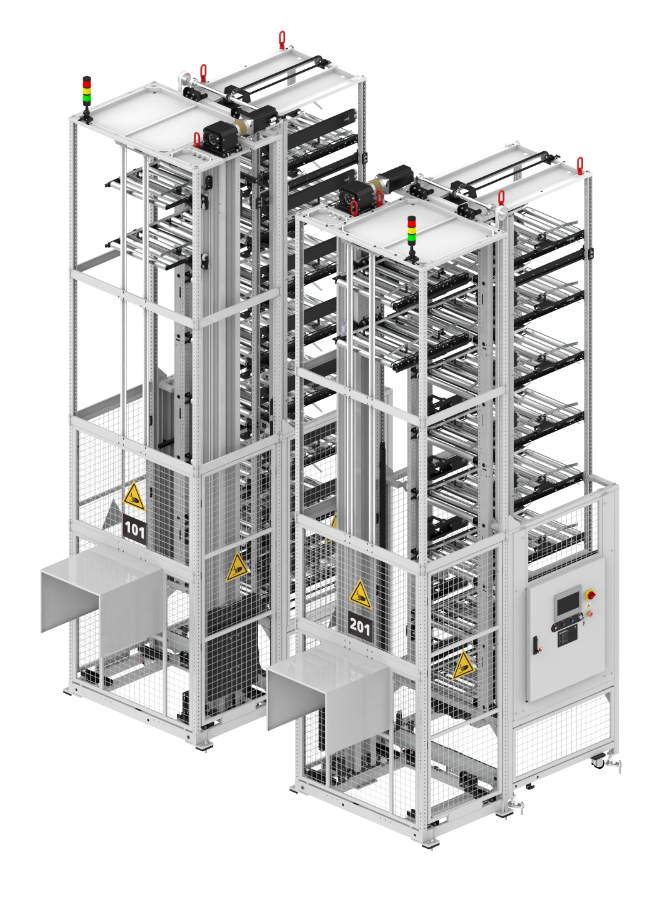

To meet the demand for the 618 online shopping festival, SF-DHL in Shanghai sought an efficient, intelligent, and flexible automation solution. The goal was to improve overall operation efficiency, reduce labor costs, and optimize storage density. HAI ROBOTICS provided a solution that included 9 units of HAIPICK A42, 3 workstations, and HAIQ Software Platform. The warehouse area is 2,000 m2, including 1,500 m2 of shelving storage area with 20,000 storage spaces. HAI ROBOTICS delivered the project within one month, and the HAIPICK system came into operation, automating the storage, handling, transportation, and other essential processes.

The project achieved the following results:

1. Increased storage capacity

By utilizing 4.2m high HAIPICK A42 robot, the warehouse can now utilize 4m high shelves, resulting in 60% increased storage density. This has enabled the warehouse to store an average of 10 standard cases per square meter.

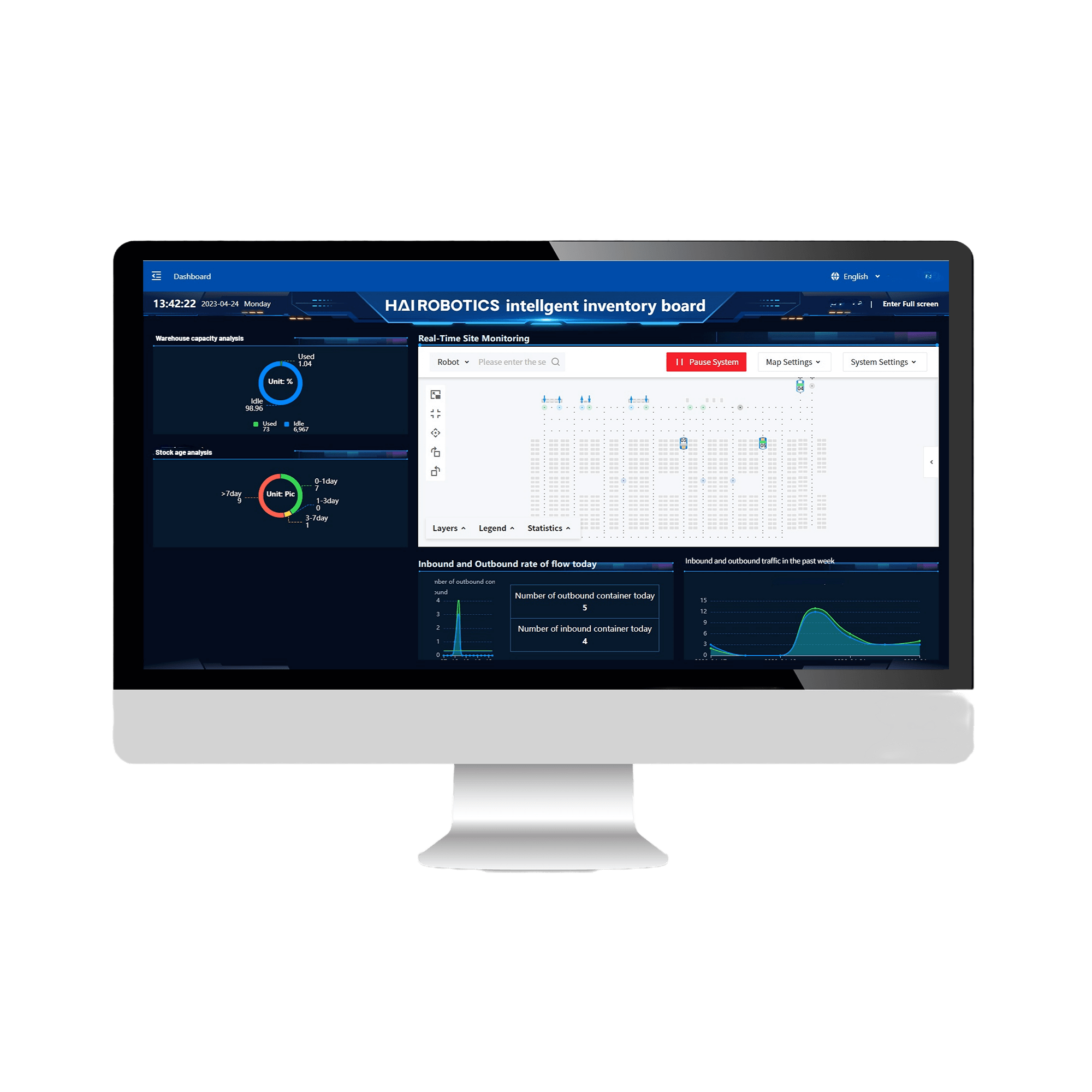

2. Kanban visual management system

The warehouse now boasts an easy-to-use Kanban visual management system. It provides operators and managers with an efficient and accurate information management system that tracks orders and robots' status in the warehouse.

3. Rapid deployment

The deployment of the system was completed within a week in a 2,000 square meter warehouse. Commissioning of the system took only one month, meeting the project's urgent delivery requirements. This enabled the warehouse to successfully complete the operations for one of China's biggest online shopping festivals.

4. Improved operational efficiency

The combination of HAI ROBOTICS' self-developed path planning and depth algorithm with the HAIQ Software Platform has enabled the warehouse to simultaneously dispatch 9 HAIPICK robots. These robots work together to intelligently handle, sort, and accurately store cases, resulting in improved inbound and outbound efficiency. The warehouse can now store over 2,500 pieces of clothing and pick and distribute nearly 700 pieces of clothing every hour. The efficiency of storage and delivery has increased by 20 times and 3.5 times, respectively.

With Hai Robotics' solution, the company transformed and improved overall operation efficiency, reduced labour costs, and optimized storage density.

With Hai Robotics' solution, the company transformed and improved overall operation efficiency, reduced labour costs, and optimized storage density.

Downloads

SF-DHL was looking for an efficient, intelligent, and flexible automation solution. The automation transformation project aimed to improve overall operation efficiency, reduce labor costs, and optimize storage density.

Download our latest industry report and learn how ACR powers different sectors. You'll learn exactly what ACR is and why it's different and so powerful.

Download the white paper and discover what industry leaders think about the future of warehouse automation, the impact it would have on workforces and sustainability, the risks facing the industry, and the potential avenues for collaboration to drive forward progress.