Sinocare

Semi-finished Pharmaceuticals Warehouse

10,652

Storage Locations within 1096㎡

200 totes

Inbound Efficiency Per Hour

13 totes/㎡

Storage Density

99.9%

Picking Accuracy

Sinocare’s traditional, manual storage method of the wide array of delicate goods was falling behind growing consumer demand. Relying solely on arduous manual picking methods by workers was inconsistent at best for their inbound and outbound workflows.

Compounding their problem was their poor use of existing storage space. Sinocare couldn’t fully utilize its vertical storage space due to how inconvenient it was for workers to get up to high spaces to retrieve and stow goods. With their storage space growing more insufficient by the day, Sinocare realized that they would soon not meet future production needs, and thus fall short of consumer demands.

The last obstacle preventing the industry leader from achieving storage success was their disjointed and erratic data management. Workers still conducted all warehouse management with manual paperwork, which meant they couldn’t connect any data to a manufacturing execution system.

This rigid, traditional paper system was prone to errors, and severe lags in data analysis meant that Sinocare may not be able to respond well to real-time consumer demand which could lead to backlogs and dissatisfied customers.

Deciding to upgrade its traditional manual warehouse into an intelligent, hybrid automation system meant a serious change for Sinocare. The global pharmaceutical leader evaluated many vendors to assess which company was the best fit for their situation.

The company determined Hai Robotics' ASRS system powered by its principal product, the Autonomous Case handling Robot (ACR) would greatly optimize its entire warehouse workflow. Sinocare trusted that the ACR solution would go above and beyond to address the challenges to its production and expansion.

Pain Points

--Inefficient outbound and inbound workflow:

Semi-finished product storage relying on inconsistent and arduous manual handling.

--Insufficient storage space:

The current storage capacity limit of 7,500 cases will not meet future production.

--Lack of digital connectivity & integration:

Manual paper warehouse management cannot connect to its manufacturing execution system (MES).

Our Solution

Sinocare Implemented the Following Units For its own HaiPick System 3 Solution:

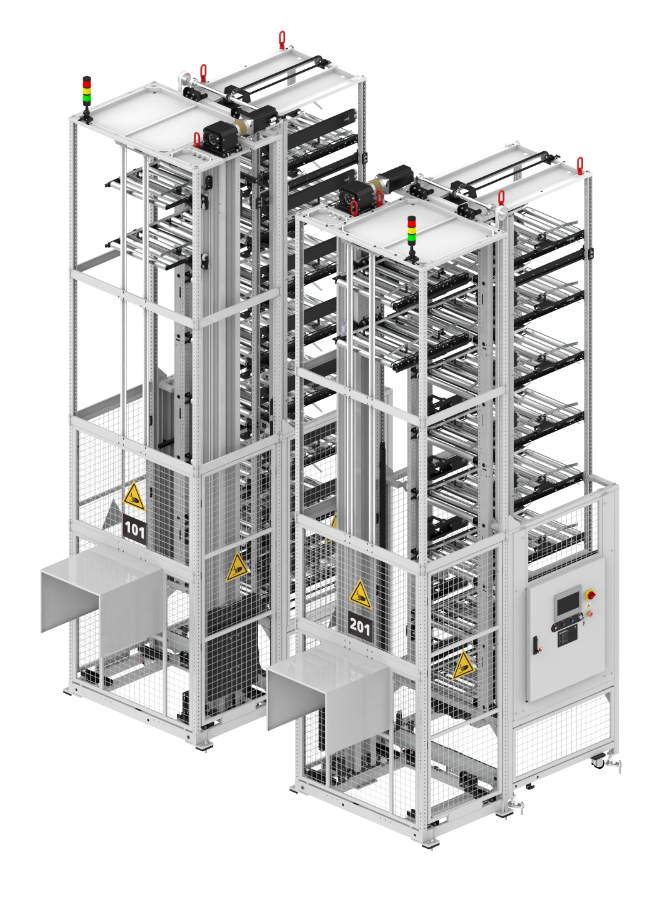

• Six HaiPick ACR A42D units for double-deep high-density storage shelving.

• Four compact AMR for agile tote transportation.

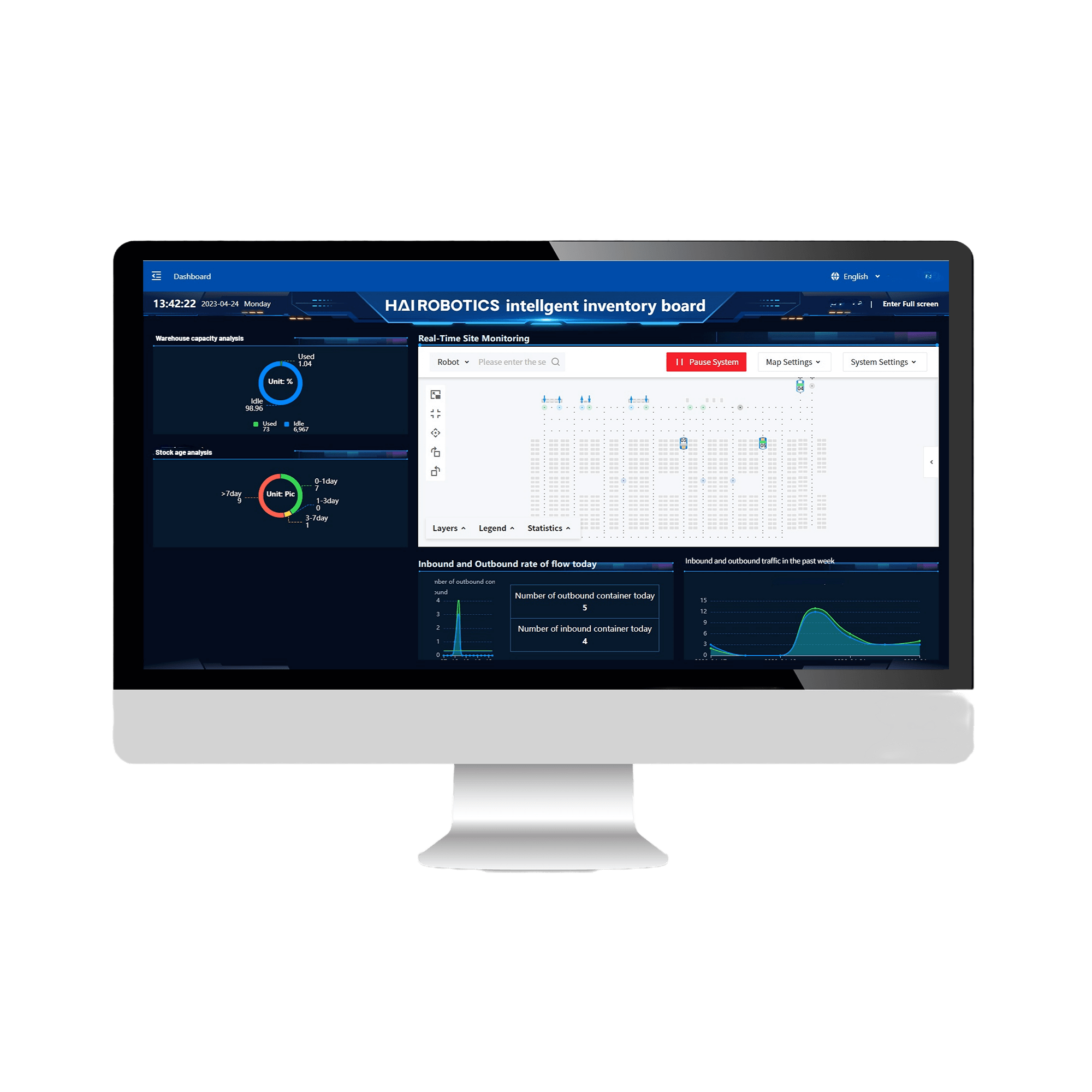

• The comprehensive and intelligent HaiQ software digitally manages the HaiPick ACR and the AMR units and fluidly links up to Sinocare’s Electric Cloud Storage (ECS) system.

• A manual buffer wall as an outbound workstation.

• Two charging stations for the HaiPick ACR, and two for the AMR units.

From inbound to inventory, HaiPick System 3 performs to solve Sinocare’s pain points in a cost-effective and flexible way.

* Inbound Success:

Sinocare’s partnership with Hai Robotics resulted in an increase in warehouse storage locations from 7500 to 10,652, in the 1,096m² warehouse area. The system fully loaded the healthcare facility’s storage density to an impressive capacity of 13 totes per m². The A42D ACR units worked seamlessly with the pharmaceutical company’s previously installed manufacturing equipment, such as their mechanical arms by automatically transporting the containers from the inbound conveyor to their proper inbound storage locations. The shelving units Sinocare worked with Hai Robotics to implement also improved its storage space by increasing the height of the shelves to a maximum shelf height of 4.4m. Sinocare’s inbound efficiency increased from 150 to 200 totes per hour due to Hai Robotics’ improvements.

* Outbound Success:

For Sinocare’s hybrid-automated outbound process, the HaiPick ACR also integrated smoothly to receive outbound tasks and arrive at designated positions in a timely manner. The pharmaceutical company was pleased that the ACR can move six 600mm(L)×400mm(W)×340mm(H) containers at once to the buffer rack. Sinocare’s efficiency greatly improved as well with the introduction of the supplied AMR. The tailor-made AMR swiftly secures and transports containers from the rack to the production line to complete outbound tasks. The AMR boosts the container to make it near effortless for Sinocare’s valued workers to remove the goods and put them into the assembly line.

* Inventory Success:

Sinocare greatly enjoyed the HaiQ software platform to accomplish the digital management of inbound, outbound, inventory, and stock-taking processes, including controlling each ACR and AMR unit, to achieve user-friendly intelligent warehousing. The HaiQ software allowed Sinocare’s workers to tap into the full advantages of a goods-to-person process. When checking their system inventory, Sinocare’s electric cloud storage (ECS) software system links instantly to the HaiQ intelligent software solution and completes all inventory checks. The streamlined teamwork of the HaiQ software system, the ACR and AMR units managed by the software, and Sinocare’s employees accomplish a significantly improved inventory process with heightened peak efficiency.

Sinocare used HaiPick System 3 to completely transform its operations into an ultramodern facility, capable of maintaining a competitive edge over its key industry rivals. Scalable and portable, the entire system can be easily relocated if Sinocare decides to add onto the system or even move its operations in the future. The respected pharmaceutical leader remains a staunch partner of Hai Robotics and regards them highly for helping them better serve their customers and communities around the world.

“The future of the big health industry will witness the inevitable trend of deep integration and advancement of the smart supply chain in the medical device health manufacturing sector. Sinocare is committed to leveraging digital transformation to achieve optimal performance growth in the industry."

“The future of the big health industry will witness the inevitable trend of deep integration and advancement of the smart supply chain in the medical device health manufacturing sector. Sinocare is committed to leveraging digital transformation to achieve optimal performance growth in the industry."

Download

How pharmaceutical leader Sinocare triumphed over inefficient workflows, insufficient storage space, and outdated paper management by partnering with Hai Robotics.

Download our latest industry report and learn how ACR powers different sectors. You'll learn exactly what ACR is and why it's different and so powerful.