Hai Robotics Automates Philips Zhuhai Factory

After one year of evaluation, Philips chose Hai Robotics to automate its Zhuhai Factory, making the first step into intelligent manufacturing. With the emergence of a range of logistics robotics solutions, Philips quickly build an intelligent and automated supply chain.

With business development, manufacturers have to improve productivity to meet the demand. After one year of evaluation, Philips chose Hai Robotics to automate its Zhuhai Factory, making the first step into intelligent manufacturing.

Automated Philips Zhuaihai Factory

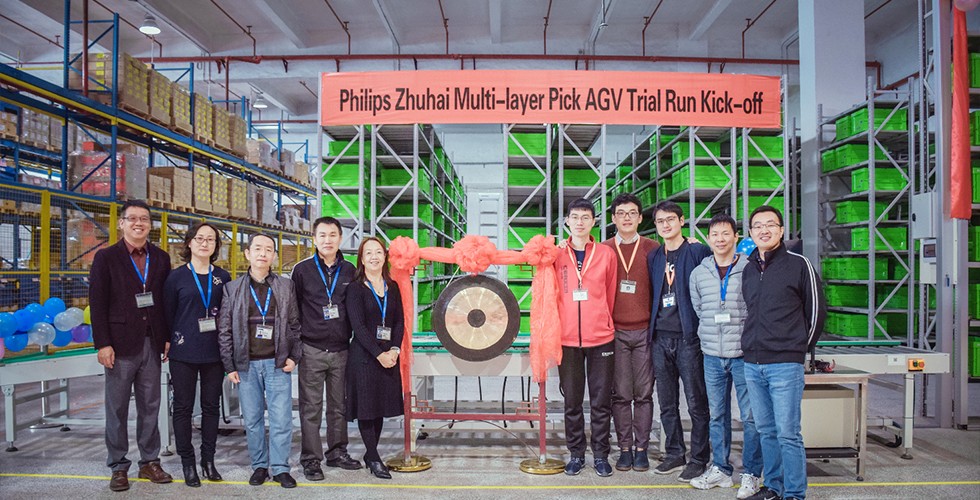

On 9th December, Anura De Silva, the General Manager of Philips Zhuhai, and Richie Chen, the CEO of Hai Robotics, attended the opening ceremony and announced that the HaiPick warehouse was officially launched.

In the solution, HaiPick robots will interact with the conveyor system to optimize the operation process. Therefore, the working efficiency will be increased by 4 times. Also, the storage density will be increased by 80% because of the 4-meter shelving.

Using Hai Robotics' advanced warehouse robots, Philips will be able to simplify its warehouse operations and improve supply chain flexibility through digitization. With the emergence of a range of logistics robotics solutions that can be flexibly adjusted and easily implemented, Philips will achieve a rapid return on investment and quickly build an intelligent and automated supply chain.

Related Article-