HaiCharger

Hai Robotics offers a one-stop solution, customizing comprehensive charging systems based on customer business scenarios and warehousing automation needs, optimizing space utilization and reducing operating costs.

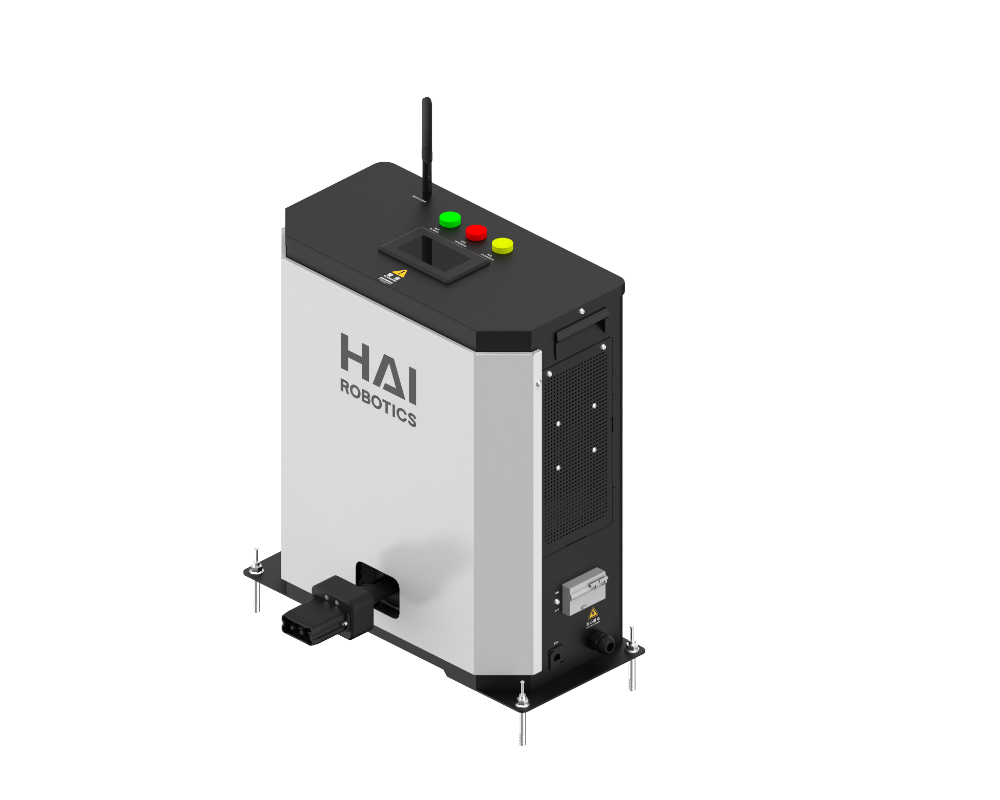

The charging station, developed independently by Hai Robotics, is a DC charging product designed for intelligent charging of ACR and AMR robots. It features a user-friendly display showing machine status, including connection, charging, and communication. The station offers various interfaces and functions, ensuring ease of use. Through an Ethernet port, a management system can remotely monitor charging status between the station and the robot. This charging product integrates multiple protection mechanisms, providing safe and reliable DC charging services.

Charging Station

- Convenient & Fast: Easy to install, operate, and maintain with a plug-and-play design for maximum convenience.

- Real-time Display: Features a 4.3-inch LCD screen that shows the charging and communication status in real-time.

- Three Operation Modes: Includes manual, automatic, and recovery modes.

- Smart Charging: Utilizes a preset charging curve, dynamically adjusting voltage and current.

- Rapid Charging: Charges a 42 Ah battery fully in just 1 hour, or in 32 minutes using fast charge mode.

- Comprehensive Protection: Equipped with voltage limit, overheat protection, current limit, short circuit protection, reverse polarity protection, and anti-shock protection.

- Built for Harsh Environments: Designed with industrial-grade components to withstand extreme conditions.