What Makes HaiPick System 3 the Right Choice?

HaiPick System 3 offers a smarter path to warehouse automation, with two distinct approaches tailored to your operational priorities. Whether your challenge is handling diverse load types or maximizing storage density, HaiPick System 3 gives you the right solution for the job.

6x

Storage Density

75%

Less Storage Footprint

3x

Higher Daily Throughput

99%+

Order Picking Accuracy

67%

Lower Labor Costs

24/7

Ready Automation

How Does HaiPick System 3 Work?

HaiPick System 3 combines two types of warehouse robots, HaiPick Robots (Automated Case‑handling Mobile Robots) and Fast-Transit Companion AMRs, to accelerate automated storage and retrieval. Each HaiPick Robot navigates narrow aisles in between racks in densely packed storage zones to handle goods for putaway and picking, while Companion AMRs transport said goods from and to workstations for inbound and outbound processing. By orchestrating the flow of goods from storage to order fulfillment, the system speeds up operations, reduces manual handling, and adapts flexibly as demand changes.

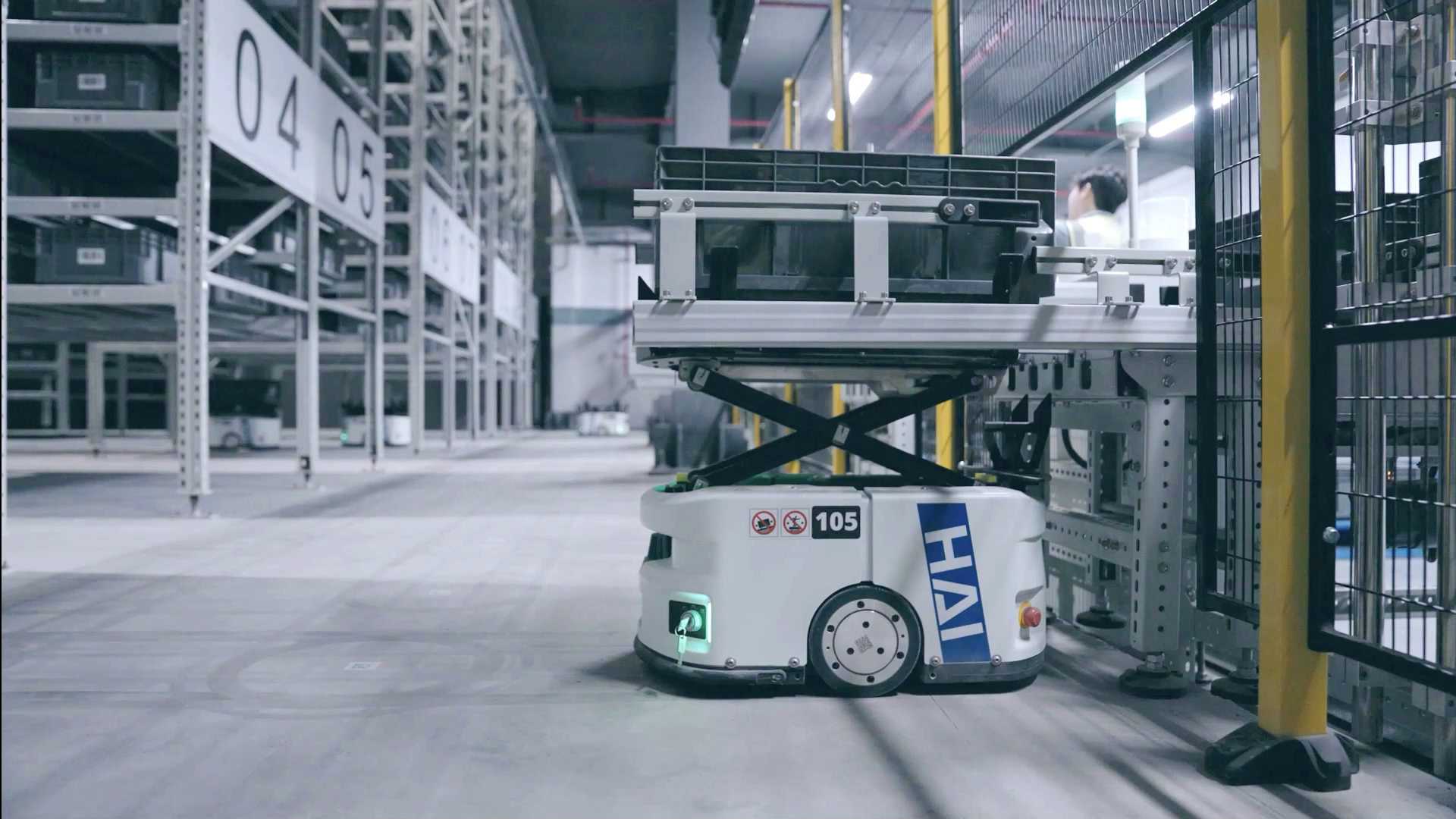

Rapid and Agile Transport with Companion AMRs

Companion AMRs keep goods moving quickly between workstations and storage, ensuring smooth inbound and outbound flows. Companion AMRs can:

-

Carry totes from inbound workstations to buffer areas for HaiPick Robots pickup

-

Deliver totes from buffer areas to outbound workstations

-

Speed up to 4 m/s for higher overall throughput

Efficient Storage and Retrieval with HaiPick Robots

HaiPick Robots perform all storage and retrieval tasks with precision and speed, enabling ultra-dense storage while ensuring fast, accurate access to inventory. HaiPick Robots can:

-

Reach up to 12 meters in height

-

Support triple-deep picking

-

Handle totes up to 50 kg and 850×650 mm

Versatile Workstations for Every Workflow

Not every warehouse runs the same way. That’s why HaiPick System 3 provides different workstation options for automation. Whether you need seamless integration with existing conveyor lines, direct handling of original packaging without decanting, or compact desktop workstations for efficient picking, the system adapts to your business needs instead of forcing you to change it.

Highlights of HaiPick System 3

Store More Without Expanding Your Footprint

Rising storage demand and limited space often lead to costly expansion. HaiPick System 3 uses Chain-Pick technology to achieve up to triple-deep storage, eliminating front-to-back gaps between totes and dramatically improving density.

-

Triple‑Deep Storage: Enabled by Chain‑Pick technology, storing up to 43,000 totes in 1,000 square meters.

-

Ultra‑Efficient Layout: Chain‑Pick totes maximize space efficiency, while telescopic HaiPick Robots reach up to 12 m and support overhead racking above 5.8 m for full vertical utilization.

0 mm

front-to-back gaps

40 mm*

side-to-side gaps

*This value may vary depending on local fire regulations.

12m

vertical storage

5.8m

Above 5.8 m overhead racking

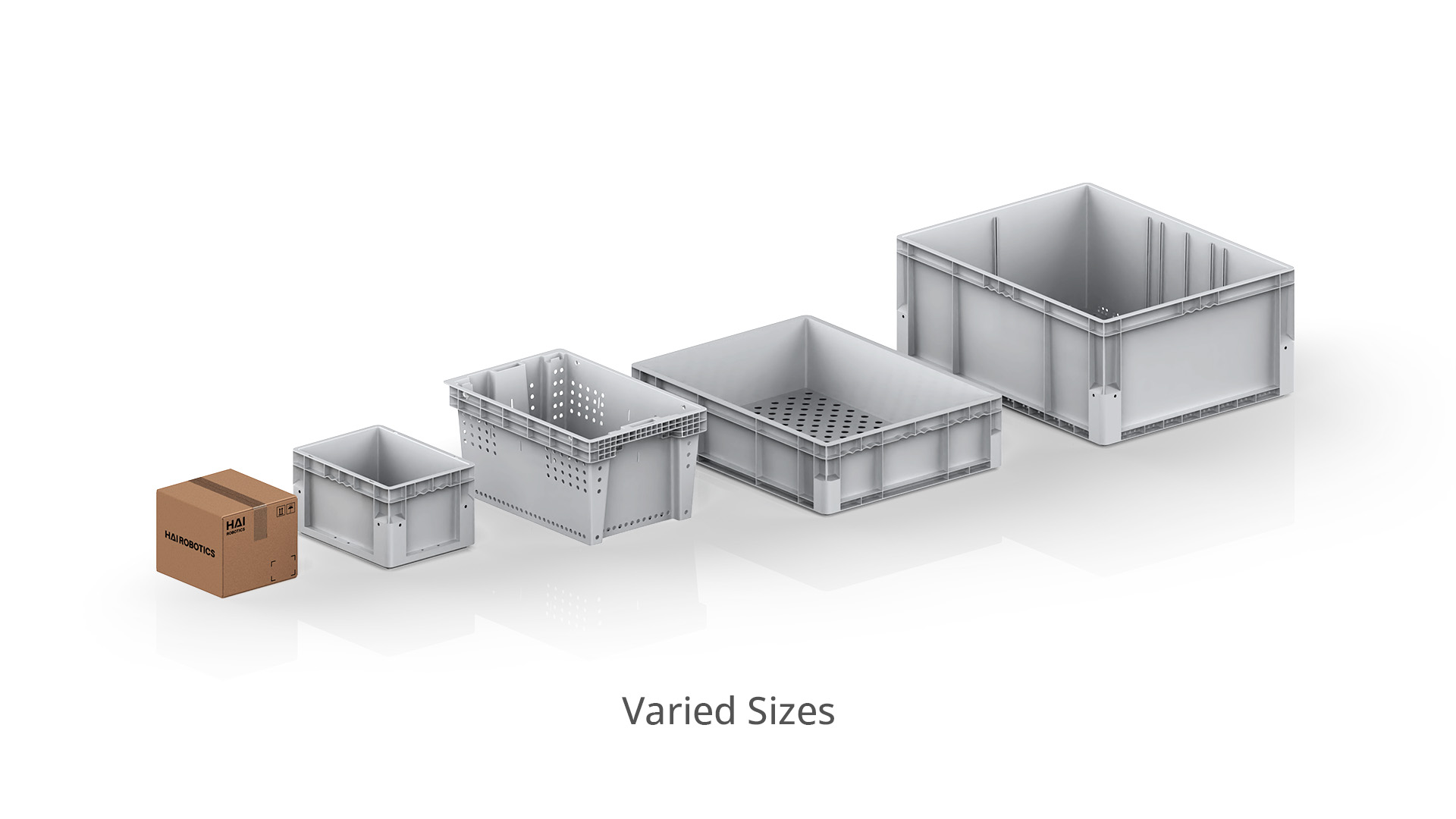

Handle Any Container in One Automated Warehouse System

Managing mixed SKU sizes and different container types often complicates operations and forces multiple workflows. HaiPick System 3 brings true warehouse automation by working seamlessly with totes, cartons, and trays, with trays enabling the storage of goods in their original packaging. This flexibility eliminates separate processes and gives ASRS warehouses the agility to manage even the most complex inventories.

Key capabilities include:

-

Varied Sizes: Handles totes and cartons from 300×300 mm to 850×650 mm within the same system.

-

Varied Types: Works with totes, trays, cartons, and customer-owned containers using adaptive gripping.

-

Flexible Configurations: Consolidation or fine segmentation, depending on needs.

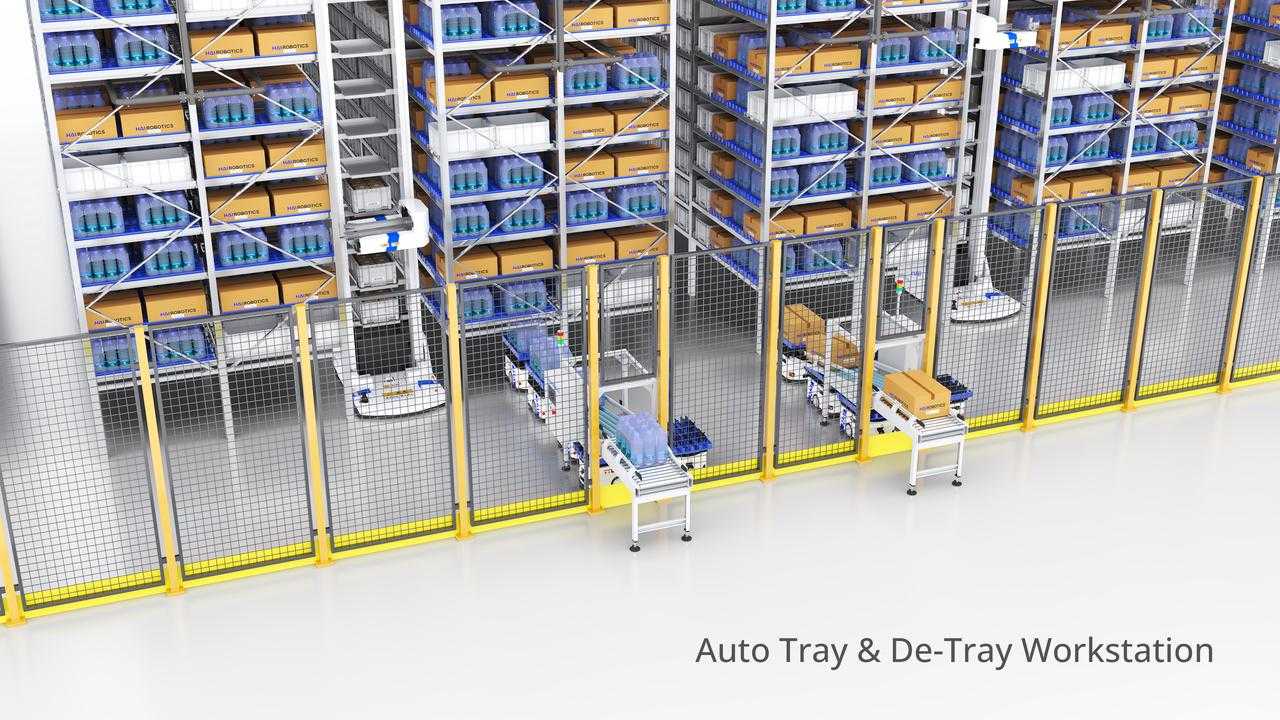

Speed Up Automated Warehouse Operations and Cut Waste

Manual decanting and container switching can eat up time, labor, and packaging resources. With HaiPick System 3, you can keep products in their original packaging and let the system handle full cases in and out automatically. By removing repetitive tasks, HaiPick System 3 keeps automated operations fast, clean, and cost‑efficient.

-

Auto Tray and De‑Tray: Supports full‑case in/out for faster order fulfillment.

-

Original Packaging Handling: Eliminates decanting to save labor and materials.

Ensure Safety Without Sacrificing ASRS Uptime

Routine maintenance or inspection no longer means downtime. With smart HaiVest, staff can enter the automation zone safely at any time. Robots pause only when someone is nearby and automatically resume when the area is clear, keeping your team safe while maximizing system uptime.

-

Smart HaiVest: Allow safe human access to automation zones.

-

Dynamic Robot Response: Robots pause when staff approach and resume automatically.

Proven Results with HaiPick System 3

From food and beverage to fashion, e-commerce, and automotive warehousing, HaiPick System 3 adapts to diverse needs by handling goods in mixed container sizes and even in their original packaging. This flexibility eliminates unnecessary decanting, saves labor, and keeps operations efficient.

Discover how global brands like KOHLER, Lenovo, and NEPA have transformed their operations with HaiPick System 3 in our customer case studies.

Discover HaiPick System 3 Yourself

Experience HaiPick System 3 in our Virtual Warehouse and see how it can transform your facility before implementing warehouse automation.

HaiPick System 3 Brochure